Page 29

BOILERMA

TE

A-CL

ASS

SP

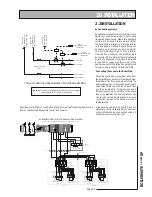

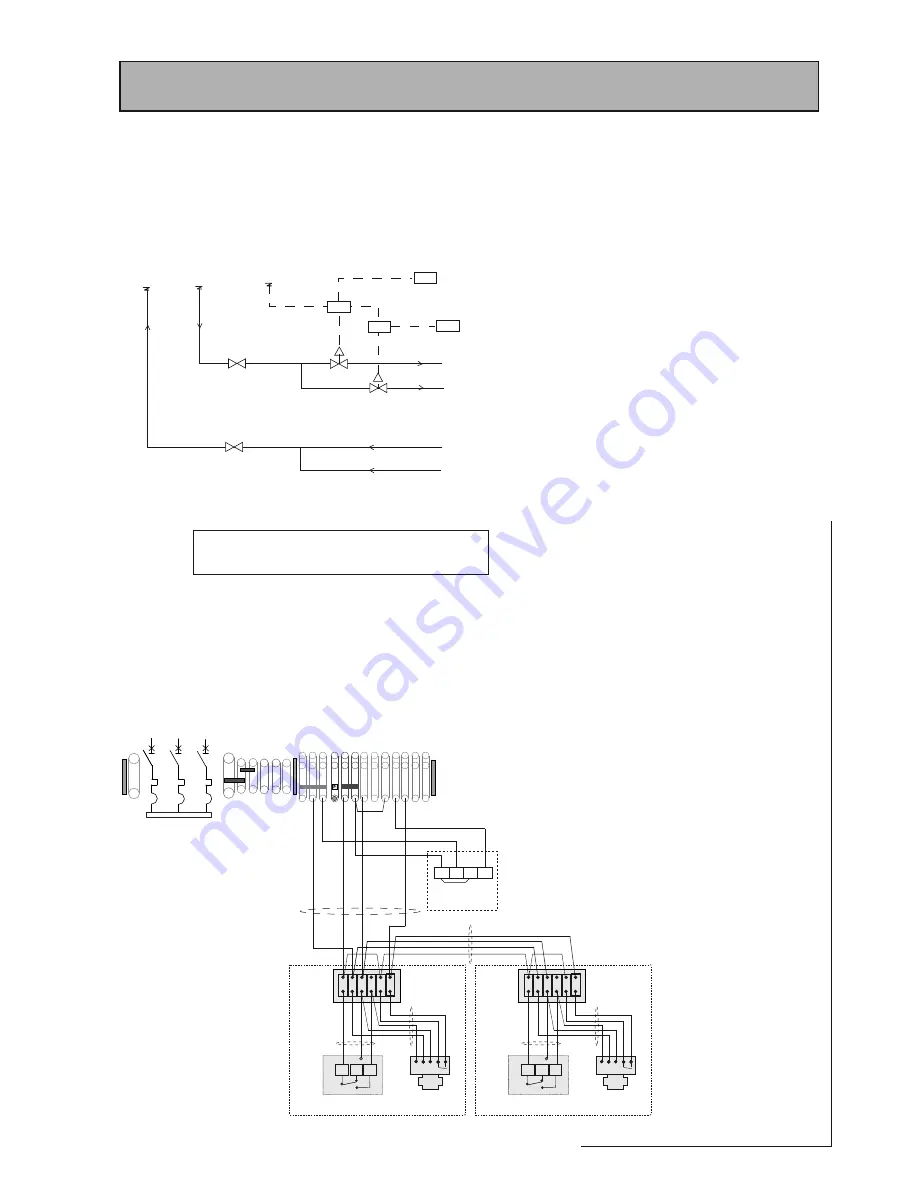

Zoned heating systems

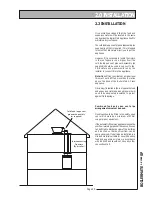

BoilerMate is available in a no clock/multi-zone

version for use where a property has to have

its space heating zoned. Where this appliance

version is to be used it is recommended that

the BoilerMate is located on a raised platform

in the cupboard creating a space below the

appliance to locate the zoning equipment.

The recommended height of the platform

from the fl oor is 250mm. The platform must

be constructed in a material that will not easily

deteriorate if exposed to moisture. It must also

be capable of supporting the weight of the

appliance when full. Details of the weight when

full is provided in section 1.2 Technical Data.

1

COM

2

OFF

3

ON

E

L

E

N

AS

TP5000 Programmable room

Thermostat

Zone valve Spring return

with auxiliary switch

Junction Box

3 core 0.75mm²

flex

L2

L N E

AS

E

1

2

3

COM OFF ON

L1

SL

E

N

L

5 Core flex from

zone valve

1

COM

2

OFF

3

ON

E

L

E

N

AS

TP5000 Programmable room

Thermostat

Zone valve Spring return

with auxiliary switch

Junction Box

3 core 0.75mm²

flex

L2

L N E

AS

E

1

2

3

COM OFF ON

L1

SL

E

N

L

5 Core flex from

zone valve

1

2

3

4

Single channel

Grasslin clock

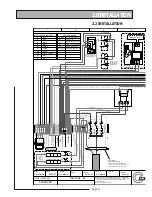

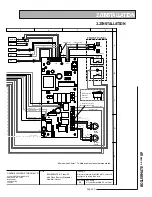

BOILERMATE MULTI-ZONE EXTERNAL WIRING DIAGRAM

Note: Terminals L3 AND SL-H must be linked in a no clock/multi-zone option.

MCB 2

MCB 1

MCB 3

16A

6A

16A

N

E

SL-W

SL-B

SL-R

L1

L2

L3

N

N

N

SL-F

N-IH

L-IH

L-IH

SL-H

E

E

PE-IH

Zone 1

Hot Water Time

Control

Zone 2

4 Core cable

4 Core cable

2.2 INSTALLATION

2.0 INSTALLATION

Connecting the zones to the BoilerMate.

The space heating fl ow should be taken from

the BoilerMate connection into the space below

the platform. The fl ow can now be split into the

appropriate amount of zones and a controlling

zone valve fitted to each branch. Each flow

can then be piped to its radiator zone and

the heating return brought back to the space

below the platform. The heating returns can

now be connected together before a single

connection is made to the heating return on

the BoilerMate.

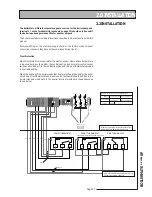

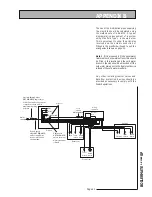

A typical way of providing heating and hot

water time control is shown below. However,

other methods can be used such as using a 3

channel programmer if required.

-ANUAL)SOLATING

6ALVES

#

ONNEC

TION

TO"OILER-

AT

E30

HEATINGR

ETURNPIPE

#

ONNEC

TION

TO"OILER-

AT

E30

HEATINGFLO

WPIPE

#

ONNEC

TION

TO"OILER-

AT

E30

ELECT

ERMINALS

:ONE

0ROGRAMMABLEROOM

THERMOSTAT

:ONE

0ROGRAMMABLEROOM

THERMOSTAT

:ONE&LOW

:ONE&LOW

:ONE2ETURN

:ONE2ETURN

490)#!,3#(%-!4)#!22!.'%-%.4/&-5,4):/.%(%!4).'

./4%/.,9:/.%3!2%3(/7.&/2#,!2)49"54&524(%2:/.%3

#!."%!$$%$).4(%3!-%7!9)&2%15)2%$

Note: Remove link from L1 to SLR when fi tting time controls for heating. Remove link

from L2 to SLW when fi tting time control for hot water.

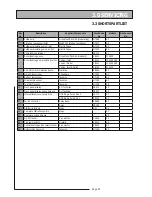

Summary of Contents for BMA 120 SP

Page 44: ...Page 44 ...

Page 45: ...Page 45 BOILERMATE A CLASS SP ...