Page 33

BOILERMA

TE

A-CL

ASS

SP

This product is covered by the ‘Benchmark’

scheme and a separate commissioning/

service log book is included with this

product. This must be completed during

commissioning and left with the product

to meet the Warranty conditions offered

by Gledhill.

These Instructions should be placed along with

the component manufacturers instructions in the

pocket provided on the rear of the front panel.

The front panel should then be refi tted.

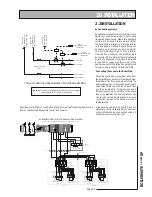

2.3 COMMISSIONING

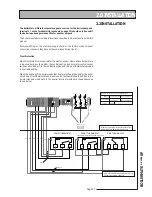

Commissioning Space Heating

(a) The central heating is best commissioned when the store is hot and therefore

should be carried out after commissioning the BoilerMate.

(b) Move the central heating control rocker to the constant position, set heating

programmer to continuous and ensure that the room thermostat is calling for heat.

This will be indicated by display segments V1.3 and V1.4 being on respectively. The

BoilerMate controller will now:-

• Open the 3 port valve to mid position to turn on the central heating. This will be

indicated by display segment V2.3 being lit. Display segment H2.3 will be on and V2.1

will be on when the boiler is fi ring. In normal operation the store temperature will

need to reach 57ºC before the valve is allowed to operate.

Once the store is fully heated (normally 75ºC) the 3 port valve will move over fully to

the central heating position.

Note: The controller is set to give hot water priority and if the store temperature drops

below 60ºC the 3 port valve will move back to the hot water only position.

(c) Wait until the heating circuit has reached its normal temperature before balancing

the system in the usual way to achieve a temperature drop of about 10

o

C.

(d) Set the programmer and room thermostat as per manufacturer’s instructions

supplied with the appliance and ensure that the programmer instructions along with

the user instructions for the appliance are left with the user.

NOTE: With sealed heating systems air is released from the water during the fi rst

few weeks of operation. This must be vented and the system repressurized.

Commissioning Domestic Hot Water System

(a) When the store is hot, open a hot water tap nearest to the appliance at

approximately 6 litres/minute. After about 2 – 3 seconds, the plate heat exchanger

pump will start. This is indicated on the A.C.B. by display segment H2.1.

(b) The hot water fl ow temperature should settle at about 52ºC. Close this tap and

open the hot bath tap at maximum fl ow rate and record the fl ow rate and the hot

water temperature in the ‘Benchmark’ logbook.

(c) Close the hot water tap(s) and after few seconds, the plate heat exchanger pump

will stop running and display segment H2.1 will turn off.

NOTE: It is recommended that the hot water rocker is left on constant so that

hot water is always available. The central heating rocker should be left on timed

and the clock set to control the times heating is required.

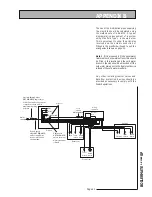

Hand over to User

(a) Explain the system and the BoilerMate appliance controls to the user.

(b) Explain how to operate the heating and hot water controls to the user. This should

include setting ‘on’ and ‘off’ times and the room temperature on the room thermostat

as well as the use of thermostatic radiator valves.

(c) Advise on boiler operation and maintenance advised in the boiler manual.

(d) Explain how to select and check the operation of the emergency backup electric

boiler ‘switch operation’ - if there is a failure of the boiler.

(e) Handover appliance and room thermostat user instructions and put the completed

“Benchmark” logbook and the appliance instruction manual in the pocket on the

inside of the appliance front panel.

(f ) DON’T place any clothing or other combustible materials against or on top of this

appliance.

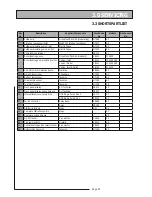

Summary of Contents for BMA 120 SP

Page 44: ...Page 44 ...

Page 45: ...Page 45 BOILERMATE A CLASS SP ...