Page 18

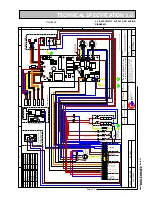

3.4 ELECTRICITY SUPPLY

AND WIRING DIAGRAMS

The mCHP_BoilerMate

A-CLASS

is fitted with a

electric backup heater rated at 6kW as standard.

Therefore the single mains electricity supply

to the appliance must be rated at 32A at 230V

ac and connected to the appliance through

a 2-pole local isolator. All fuses must be ASTA

approved to BS 1362. This supply is internally

split and fused for the control and power

circuits. This appliance MUST BE EARTHED.

The BoilerMate only supplies the control

signal power to the mCHP unit. Therefore the

mCHP unit must be connected to the mains

supply via its dedicated 2-pole isolator as

per manufacturer’s instructions.

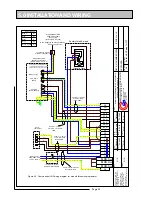

The internal wiring diagram is shown in figure

3.6 and typical external wiring arrangement is

shown schematically in figure 5.2.

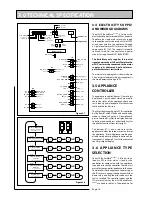

3.5 APPLIANCE

CONTROLLER

The appliance controller (figure 3.7) has a 2 digit

display and 2 push buttons which are used to

check the status of the appliance, check and

set its identity and interrogate it for the current

faults and the fault history.

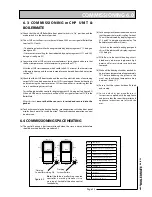

The 2 digit display on the main PCB is controlled

by 2 buttons B1 and B2 The flow chart of display

modes is shown in figure 3.8. Generally, each

press of button B1 cycles the display from top

to bottom and each press of button B2 cycles

the display functions from left to right.

The buttons B1 is also used to reset the

appliance i.e. clear the lockout errors and reset

the appliance. (Note: Appliance resetting can

also be carried out using the push button on the

front panel). See figure 6.2 for further details of

the 2 digit digital display.

3.6 APPLIANCE TYPE

SELECTION

The mCP BoilerMate

A-CLASS

is fitted with an

identity (iD) resistor which is read by the

controller for comparison with the appliance

type (code) set on the controller. The two must

match for the controller/appliance to function.

Therefore if either the appliance code setting or

the iD resistor is wrong, the appliance will shut

down safely and flag the error code until the

fault is rectified. The controller codes and the

iD resistor values for the mCHP-BoilerMate

A-

CLASS

are listed in table 3.6. The procedure for

3.0 TECHNICAL SPECIFICATION

Tank_middle

T_overh_2

T_dhw_in

ID_resistor

T_overh_1

Tank_bot

T_dhw_out

ID_resistor

ID_resistor

Ext_led_k

Ext_se_1

PC Connector

Reset

button

Enter

button

Main processor

FLIP jumper

J9

J31

J30

SEND_TO_GAS

VSS

GASV_IN

220_0

WD_RECEIVE

VSS

SAFETY

220_1

J29

DIV_OUT_2

220-0

DIV_OUT_1

220_0

EL_HEAT_OUT

BOIL_HEAT_DEM

OVERHEAT

220_0

BOIL_HEAT_DEM

CH_P_MOD

CH_P_L

CH_P_L

CH_P_PE

BOIL_P_PE

BOILER_P_MOD

BOIL_P_L

BOIL_P_N

DHW_P_PE

DHW_P_MOD

DHW_P_L

DHW_P_N

220_1

220_PE

220_0

220_PE

220_1

220_0

CH_ON_IN

220_0

220_1

SWL_IN

DHW_ON_IN

220_INPUT

J3

J33

J32

J34

J28

J5

2 digit display

B1

B2

.ORMALSTANDBYSTATE

)NDICATESYSTEMSTATUS

3EESECTION

3ENSORTEMPERATUREREADING

3EESECTION

3ETPOINTREADING

3EESECTION

&AULTCODE)NDICATION

,OCKOUTS

3EESECTION

3

3

3

3

3

3

3

3

#

#

#

#&

C

C

C

C&

!

!

!

!

&AULTCODEINDICATION

"LOCKOUTS

3EESECTION

!PPLIANCE4YPE

3EESECTIONS

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

0RESS"

"

"

Figure 3.7

Figure 3.8

Summary of Contents for mCHP BMA 225

Page 44: ......