Page 23

mCHP

BOILERMA

TE

A-CL

ASS

HEATING AND HOT WATER 4.0

4.1.2

USE IN HARD WATER

AREAS

(a) The control system prevents the domestic

water from exceeding 55

o

C for most of

the operational time of the appliance and

therefore limits the formation of scale .

(b) The Building Regulations L1A: New

dwellings/L1B: Existing dwellings and

the requirements set out in the Domestic

Heating Compliance Guide specify that

“where the mains water hardness exceeds

200ppm provision should be made to treat

the feed water to water heaters and the

hot water circuit of combination boilers

to reduce the rate of accumulation of lime

scale”.

To comply with this requirement the

hardness of the mains water should be

checked by the installer and if necessary

the optional factory fitted in-line scale

inhibitor should be specified at the time

of order for hardness levels between 200

and 300 ppm (mg/l).

Where the water is very hard ie 300ppm (mg/

l) and above the optional polyphosphate

type, inhibitor should be specified at the

time of order. However, this will need to

be fitted by the installer at a suitable point

in the cold water supply to the appliance.

(c) if scale should ever become a problem the

plate heat exchanger is easily isolated and

quickly replaced with a service exchange

unit which can be obtained at a nominal

cost from Gledhill.

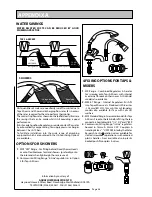

4.1.3

COLD AND HOT WATER DISTRIBUTION

NETWORK

(a) As a minimum, it is recommended that the cold supply to the appliance internally

is run in 22mm copper or equivalent in plastic and then from the appliance in

22mm past the hot water draw-off to the bath .

(b) We would recommend that best results for balanced system are achieved by

fitting appropriate flow regulators to each hot and cold water outlets. These must

be fitted in cases where the final branch pipe sizes are not as recommended in (c)

below or the water pressures are above the recommended 2 – 3 bar range.

(c) Alternatively the tee-offs to the outlets should be in 10mm except for bath and

shower, which should be in 15mm (i metre minimum length).

(d) The hot water supply to a shower-mixing valve should be the first draw-off point

on the circuit. The cold water supply to a shower-mixing valve should be fed

directly from the rising main and should be the first draw off point on the cold

water circuit.

(e) it is important that the cold water pipe work is adequately separated from any

heating/hot water pipe work to ensure that the water remains cold and of drinking

water quality.

4.1.4

TAPS AND SHOWER FITTINGS

(a) Ensure that all terminal fittings are suitable for mains pressure. Use aerated taps

whenever possible to prevent splashing.

(b) Any shower mixing valve used must be suitable for mains fed hot and cold supplies.

However all mains pressure water systems are subject to dynamic changes

particularly when other hot and cold water taps are opened and closed. For this

reason, a thermostatic shower MUST be used with this appliance.

(c) Note that the shower fittings must comply with the backflow prevention

requirements (Para 15, Schedule 2) of the Water Supply Regulations 1999.

(d) A bidet can be supplied from the mCHP BoilerMate appliance as long as it is of

the over rim flushing type and incorporates a suitable air gap.

4.1.5

DEAD LEG VOLUMES

if the dead leg volumes of the hot water draw-

off pipework is excessive and the delivery

time will be more than 60 seconds before

hot water is available at the tap, you may

consider using trace heating such as the

‘RaychemHWAT’ system. Please call Gledhill

technical department for further details.

Summary of Contents for mCHP BMA 225

Page 44: ......