Page 30

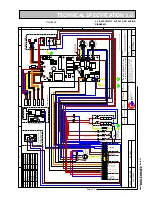

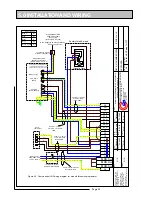

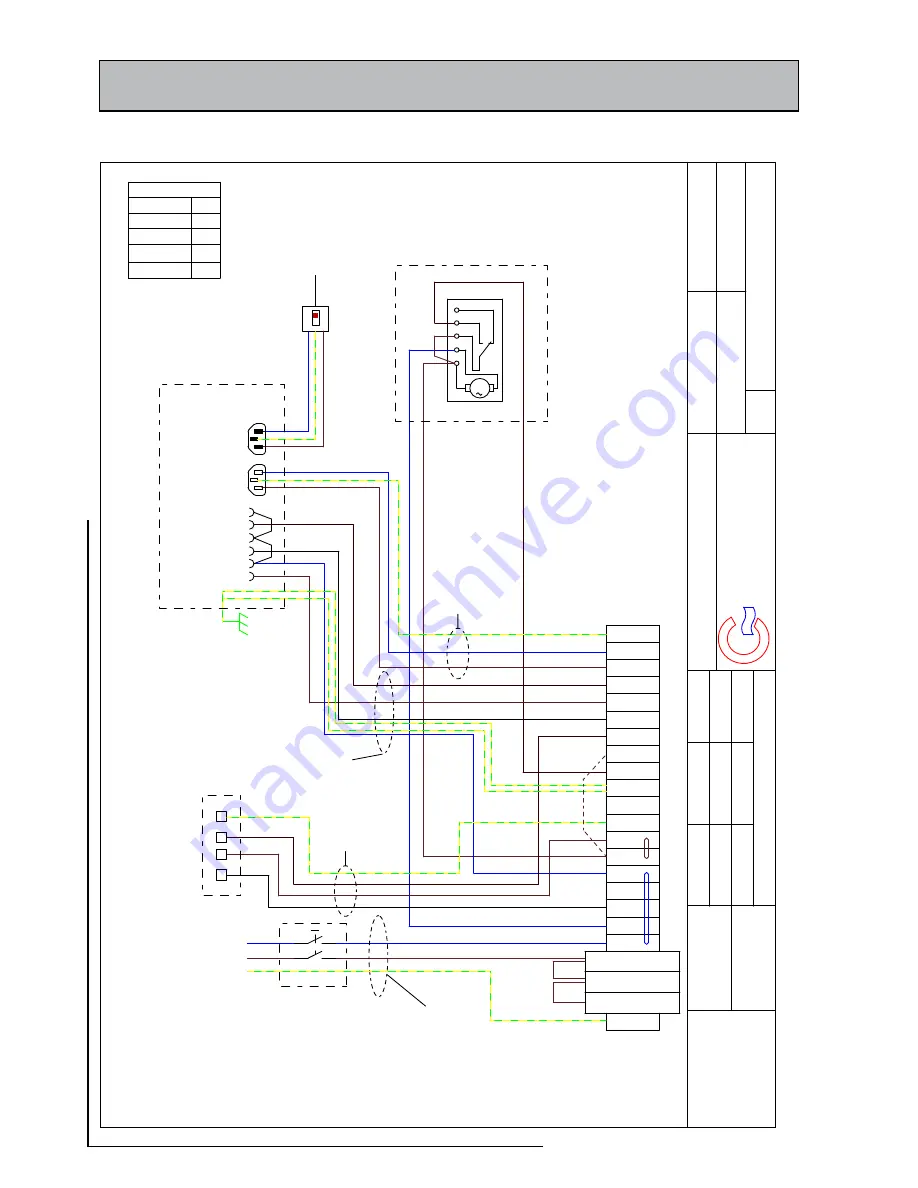

5.0 INSTALLATION AND WIRING

SYCAMORE

TRADING EST

ATE

SQUIRES GA

TE LANE

BLACKPOOL

LANCASHIRE FY4 3RL

©

N

N

N

PE

PN

PL

SL_E

SL_B

SL_O

SL_R

SL_H

SL_W

PE

PE

PE

PE

L

L

N

N

M

1

2

3

5

4

MCB 2

MCB 3

MCB 1

Grasslin Clock

Factory fitted & wired

16A

6A

16A

2

3

4

5

6

1

Mains supply

Mains supply

230V, 50Hz, 32A

(6mm² - 10mm²)

Local 2 pole isolator

within 2m of Boilermate

Local 2 pole isolator

within 2m of appliance

6 pin plug

(ELCO 300013)

CHP Pump

Supply

Room

Thermostat

WhisperGen mCHP

appliance connections

(Model : PPS2 - ACLG - 4)

WhisperGen mCHP

230V 50Hz supply

fused at 8A

(Anti surge HRC fuse)

L

SL

PE

N

0.75mm² - 1.00mm²

3 core & E cable

(230V, 50Hz)

6.0mm² Flat twin & earth

Boilermate cable

0.75mm² - 1.0mm²

3 core & E + 2 core & E

cable

0.75mm² - 1.0mm²

3 core & E cable

(230V, 50Hz)

Figure 5.4 Contols and mCHP wiring diagram for models fitted with programmer

Colour Legend

Br

Brown

Bl

Blue

B

Black

Gry

Grey

G / Y

Green / Yellow

Gry

Gry

Gry

Gry

B

B

B

B

B

Bl

Bl

Bl

Bl

Bl

Bl

Bl

G / Y

G / Y

G / Y

Wh

G / Y

G / Y

G / Y

G / Y

Br

Br

Br

Br

Br

Br

Br

Br

Br

Br

Please refer to the Installation/Service

manual supplied with the WhisperGen

appliance before making connections

ON

OFF

Note: Supply to be brought directly

from consumer unit

DO NOT SCALE FROM THIS

IT IS

NOT TO BE

REPRODUCED COPIED OR DIS

CLOS

ED TO A THIRD

PARTY EITHER WHOLLY OR IN PART WITHOUT OUR

MT'L.

FINISH

DRN.

DATE

DIMS.

CH'KD.

DATE

SCALE

APP'D.

DATE

TOL.

TITLE

DRG. NAME

DRG. SIZ

E

DRAWING. COPYRIGHT OF THIS DRAWING IS RES

ERVED .

WRITTEN CONS

ENT.

Boiler mCHP

prog 1A.FC7

A4

N /

A

N /

A

N /

A

GLEDHILL

W

ATER ST

ORAGE L

TD.

Installers Wiring Diagram for mCHP

appliance

with factory fitted programmer

22-04-05

22-04-05

22-04-05

GLEDHILL

W

ATER ST

ORAGE L

TD.

N /

A

N /

A

P. Ganderton

APPROVED

ISSUE No : 1A

DA

TE : NOVEMBER 2004

S. Gataora

S. McGachie

Summary of Contents for mCHP BMA 225

Page 44: ......