Page 8

INSTALLATION

INST

ALL

A

T

ION

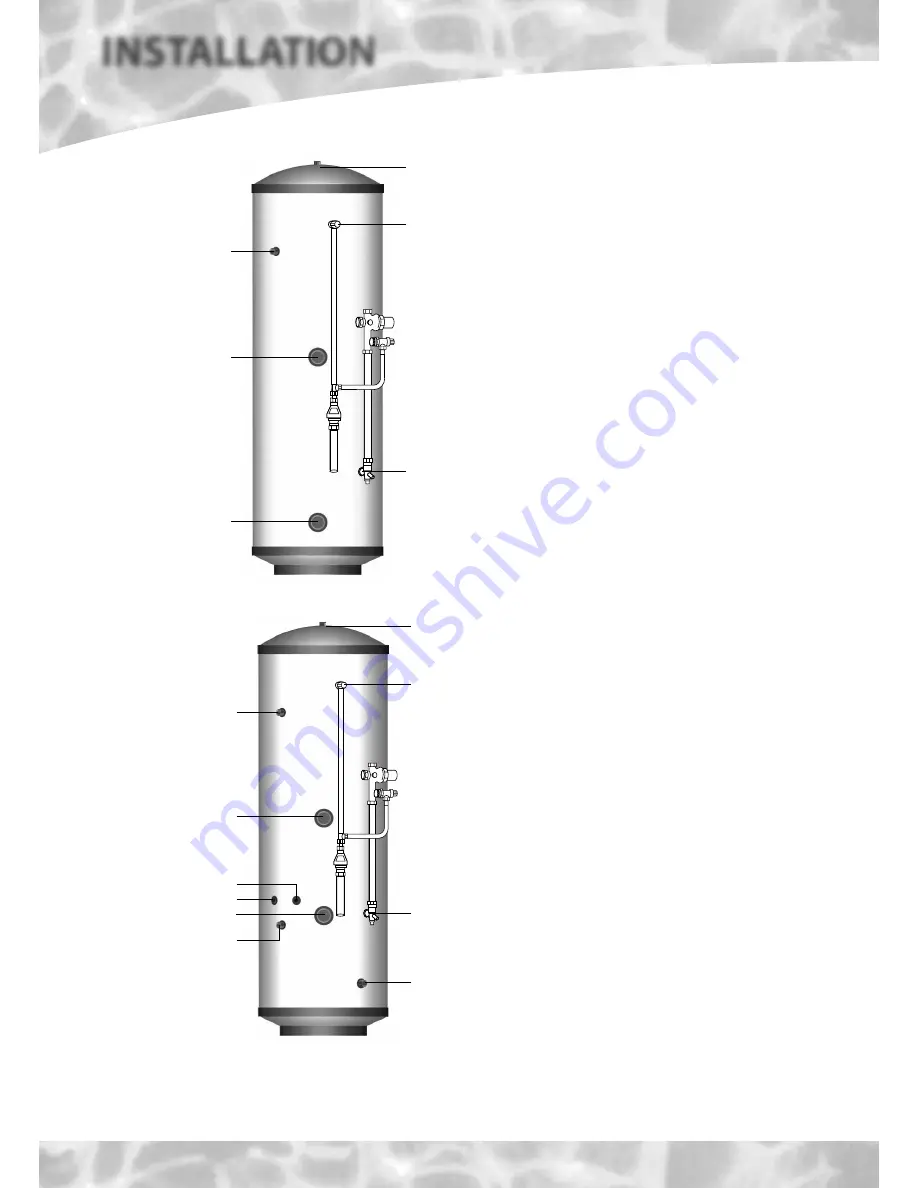

Stainless Lite Direct

Basic Appliance

1. Hot water draw off (22mm) compression

2. Temperature & pressure relief valve 90°/6 bar

3. Hot water secondary return 22mm capped

(not fi tted to smaller sizes, see table 1)

4. Immersion heater 1¾” BSP 3kW

(normally on-peak)

5. 22mm cold supply compression

6. Immersion heater 1¾” BSP 3kW

(normally off-peak)

Component kit supplied separately

A. Combination inlet group incorporating

pressure reducing valve, strainer, check

valve, balance cold take off point, expansion

relief valve and expansion vessel connection

points.

B. Portable expansion vessels c/w fl exible hose

and wall bracket

C. Tundish

Stainless Lite Indirect

Basic Appliance

1. Hot water draw off (22mm) compression

2. Temperature & pressure relief valve 90°/6 bar

3. Hot water secondary return 22mm capped

(not fi tted to smaller sizes, see table 1)

4. Immersion heater 1¾” BSP 3kW

5. 22mm cold supply compression

6. Immersion heater 1¾” BSP 3kW

7. Dual control/overheat stat pocket (22mm)

8. Boiler control sensor pocket (spare)

9. Primary return (22mm)

10. Primary fl ow (22mm))

Component kit supplied separately

A. Combination inlet group incorporating

pressure reducing valve, strainer, check

valve, balance cold take off point, expansion

relief valve and expansion vessel connection

points.

B. Potable expansion vessels c/w fl exible hose

and wall bracket

C. Tundish

D. Dual control thermostat and combined

overheat thermostat

E. Two port (22mm) zone valve for

primary circuit

F. Wiring junction box for primary system

1

2

5

3

4

6

1

2

3

4

7

5

6

9

8

10

Typical arrangement of component kit shown fi tted to the appliance for clarity

Pipework to be supplied and fi tted by installer.

Summary of Contents for Stainless Lite Direct 90-300 litres

Page 29: ...Page 29 NOTES ...