Page 16

d) It is preferable for the discharge to be visible at both the tundish and the fi nal point

of discharge but where this is not possible or practically diffi

cult there should be

clear visibility at one or other of these locations. Examples of acceptable discharge

arrangements are:

1. Ideally below the fi xed grating and above the water seal in a trapped gulley.

2. Downward discharges at a low level; i.e. up to 100mm above external surfaces

such as car parks, hard standings, grassed areas etc are acceptable providing

that where children play or otherwise come into contact with discharges, a

wire cage or similar guard is positioned to prevent contact whilst maintaining

visibility.

3. Discharges at a high level; e.g. into metal hopper and metal down pipe with the

end of the discharge pipe clearly visible (tundish visible or not) or onto a roof

capable of withstanding high temperature discharges of water and 3m from

any plastic guttering systems that would collect such discharges.

4. Where a single pipe serves a number of discharges, such as in blocks of fl ats,

the number served should be limited to not more than 6 systems so that any

installation can be traced reasonably easily. The single common discharge pipe

should be at least one pipe size larger than the largest individual discharge pipe

to be connected. If unvented hot water storage systems are installed where

discharges form safety devices may not be apparent i.e. in dwellings occupied by

blind, infi rm or disabled people, consideration should be given to the installation

of an electronically operated device to warn when discharge takes place.

Safety

The safety devices supplied or fi tted on an Stainless Lite are selected for their suitability

for the temperatures and pressures involved. They must not be changed, removed or

by-passed and it is essential that only genuine replacement parts supplied or approved

by Gledhill Building Products Limited are used. This includes the immersion heaters,

which must incorporate an energy cut-out. All parts are available to approved installers

from Gledhill Building Products Limited, Sycamore Estate, Squires Gate, Blackpool

(Telephone 01253 474402).

Combination Inlet Group

Combines elements 1, 2 and 3 below.

1.

Pressure Reducing Valve

- This must be fi xed near the cylinder. The cold water supply

to any mixer taps/showers must be taken from the cold water tapping of this valve

to ensure balanced hot and cold pressures. This valve is factory set to ensure the

correct operating pressure for the Stainless Lite.

2.

Non Return Valve

- This is integral with the pressure reducing valve to prevent

backfl ow of hot water towards cold water draw off points.

3.

Cold Water Expansion Relief Valve

- This safety device is preset at the factory and

will relieve excess cold water pressure resulting from a fault condition.

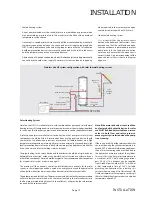

Stainless Lite HP SOL model without

solar heating system

P&T Relief Valve

Tundish

Hot Outlet

To Drain

PRV

ERV

NRV

Stop

Tap

Kitchen

Cold

Tap

Combination

Valve

Balanced

Cold

Outlets

Expansion

Vessel

Heat Pump

Return

Secondary

Return Circuit

Non Return

Valve

Pump

Stainless Lite HP SOL model with

solar heating system

Secondary

Return Circuit

Heat Pump

Flow

P&T Relief Valve

Tundish

Hot Outlet

Mixed Hot

Water Out

To Drain

PRV

ERV

NRV

Stop

Tap

Kitchen

Cold

Tap

Combination

Valve

Balanced

Cold

Outlets

Expansion

Vessel

Heat Pump

Return

Solar Return

Solar Flow

Non Return

Valve

Pump

Heat Pump

Flow

Stainless Lite HP & Slimline model

without solar heating system

P&T Relief Valve

Tundish

Hot Outlet

To Drain

PRV

ERV

NRV

Stop

Tap

Kitchen

Cold

Tap

Combination

Valve

Balanced

Cold

Outlets

Expansion

Vessel

Heat Pump

Return

Secondary

Return Circuit

Non Return

Valve

Pump

Heat Pump

Flow

INSTALLATION

INSTALLATION

Summary of Contents for Stainless Lite HP Indirect 180-400 litres

Page 30: ...Page 30 NOTES ...

Page 31: ...Page 31 NOTES ...