Page 16

Lift Up Pressure & Temperature Relief Valve

This safety device is also pre-set at the factory and relieves before the temperature

reaches 100°C. It is also a Pressure Relief Valve, and is pre-set to 6 bar.

Immersion Heaters

The immersion heaters fitted to our units are 3kW 240V ~AC. Check that the mains

supply conforms to this, and all external wiring conforms to the most recent

revision of the IEE wiring regulations. An Incoloy element is used on this product for

standard domestic use and water conditions, use our Titanium elements in all other

circumstances, part number SH002.

The immersion heater is fitted into the hot water cylinder using an O-ring. After the

unit is filled with water check for leaks to determine if the O-ring has sealed and

tighten carefully using the appropriate tool. To prevent damage to the O ring do not

use excessive force to tighten the immersion heater.

The immersion heater is supplied with a thermostat which has been tested

for operation in the cylinder and complies with the European directives for

Electromagnetic compatibility and radio interference. It is Rated at 16 Amp 250V ~AC.

Immersion Heater Wiring

E

L

N

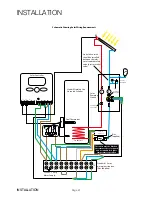

INSTALLATION

INSTALLATION

The immersion thermostat has two terminals

A and B. The Live (brown) wire should be

connected to terminal A and the Neutral (blue)

wire should be connected to terminal B. It has

been our experience that Crimp terminals make

better connections. The immersion heater must

be fully earthed (earth post) and connected via

a double pole isolator switch having a contact

separation at least 3mm, see diagram opposite.

Danger of electrocution: before making any

adjustments to the thermostat isolate the

immersion heater from the mains electricity

supply at the fuse spur unit.

The immersion heater thermostats incorporate

a manual reset safety/overheat cut out

thermostat. Should this operate, investigate the

cause for the operation cut out before pressing

the red reset button labelled safety. If there is no

apparent fault adjust the control setting down

slightly to prevent nuisance tripping.

If another heat source is used to heat the

cylinder and this is allowed to raise the water

temperature excessively then the overheat

thermostat will trip. This is likely on solar

thermal products when the solar thermostats

are set at high temperatures.

The Direct cylinder is intended to be heated

from an off peak supply using the lowest

immersion heater(s) and boosted via the upper

immersion heater from an on peak supply.

Suitable controllers are available to control this

operation effectively.

Solar Thermistors / sensors

Care must be taken to ensure that the solar probes

are fully inserted into the pockets provided.

Important

Failure to follow the drain down procedure will

invalidate the warranty. (see page 22)

NEVER

drain the cylinder of hot water and

then close all cylinder inlets and

outlets.

REASON

as the air remaining in the cylinder

cools the pressure inside the

cylinder will fall below atmospheric

and cause damage to the cylinder.

NEVER

close the cold main and drain the

cylinder via any tap connected to it.

REASON

as the water drains, the pressure

inside the cylinder may decrease

below atmospheric and this may

cause damage to the cylinder.

In line with good plumbing practice, use of

excessive flux should be avoided.

I.V.

Combination Valve

I.V.

If two Stainless Lites are coupled together the secondary inlet and outlet pipes must

be balanced. The units must be fitted on the same level.

Note: No valves must be fitted between the expansion vessel and the storage cylinder(s).

Thermostat Type TSR fitted in the

Direct cylinders; is supplied set at

62°C ± 3°C. Position 4 is 55°C ± 3°C

and position 5 is 68°C ± 3°C.

Thermostat Type TSE fitted in the

indirect cylinders - is supplied set

in position 5 at 60°C ± 4°C.

When ordering a replacement

part the TSR thermostat type will

be supplied with the immersion

heater.