Page 18

BENCHMARK

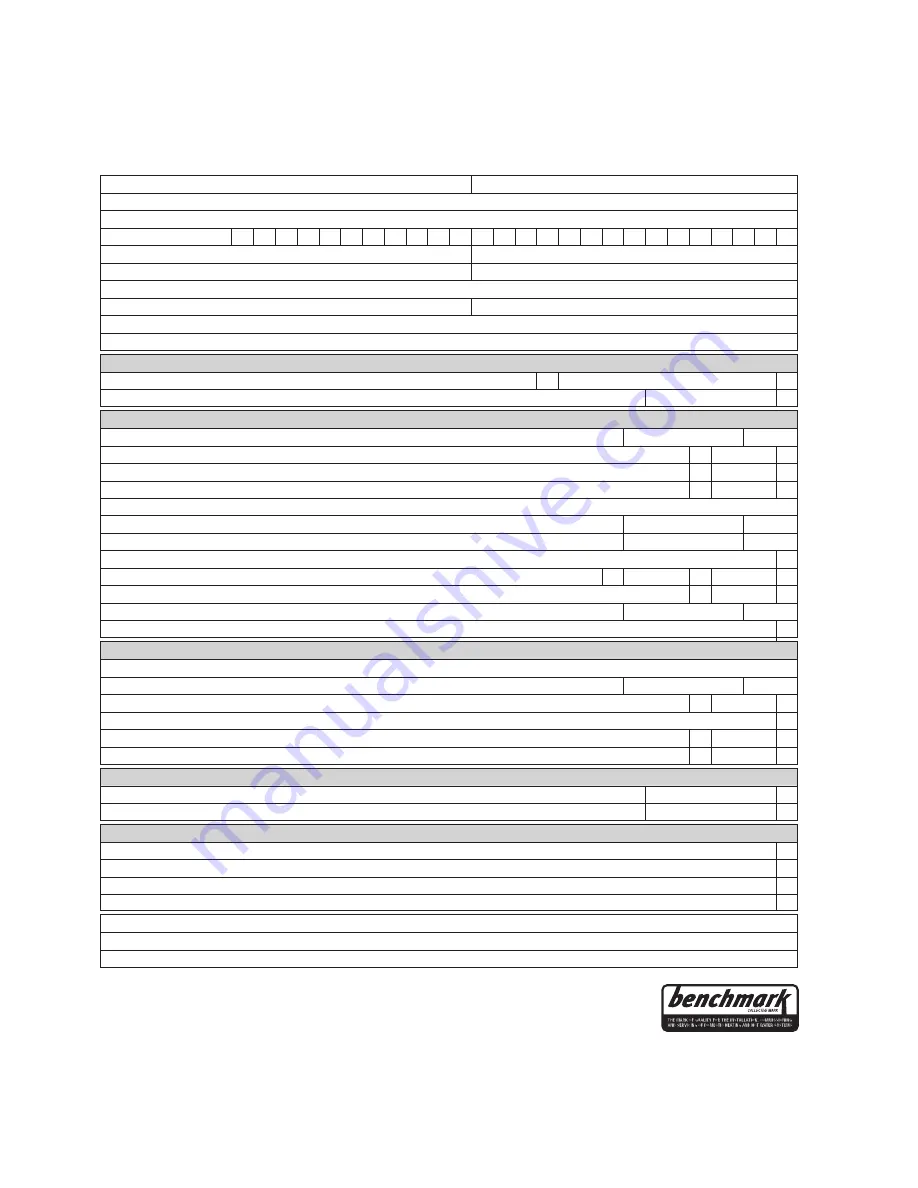

This Commissioning Checklist is to be completed in full by the competent person who commissioned the storage system as a means of

demonstrating compliance with the appropriate Building Regulations and then handed to the customer to keep for future reference.

Failure to install and commission this equipment to the manufacturer’s instructions may invalidate the warranty but does not affect statutory rights.

MAINS PRESSURE HOT WATER STORAGE SYSTEM COMMISSIONING CHECKLIST

Customer name:

Telephone number:

Address:

Cylinder Make and Model

Cylinder Serial Number

Commissioned by (PRINT NAME):

Registered Operative ID Number

Company name:

Telephone number:

Company address:

Commissioning date:

To be completed by the customer on receipt of a Building Regulations Compliance Certificate*:

Building Regulations Notification Number (if applicable)

ALL SYSTEMS PRIMARY SETTINGS

(indirect heating only)

Is the primary circuit a sealed or open vented system?

Sealed

Open

What is the maximum primary flow temperature?

°C

ALL SYSTEMS

What is the incoming static cold water pressure at the inlet to the system?

bar

Has a strainer been cleaned of installation debris (if fitted)?

Yes

No

Is the installation in a hard water area (above 200ppm)?

Yes

No

If yes, has a water scale reducer been fitted?

Yes

No

What type of scale reducer has been fitted?

What is the hot water thermostat set temperature?

°C

What is the maximum hot water flow rate at set thermostat temperature (measured at high flow outlet)?

I/min

Time and temperature controls have been fitted in compliance with Part L of the Building Regulations?

Yes

Type of control system (if applicable)

Y Plan

S Plan

Other

Is the cylinder solar (or other renewable) compatible?

Yes

No

What is the hot water temperature at the nearest outlet?

°C

All appropriate pipes have been insulated up to 1 metre or the point where they become concealed

Yes

UNVENTED SYSTEMS ONLY

Where is the pressure reducing valve situated (if fitted)?

What is the pressure reducing valve setting?

bar

Has a combined temperature and pressure relief valve and expansion valve been fitted and discharge tested?

Yes

No

The tundish and discharge pipework have been connected and terminated to Part G of the Building Regulations

Yes

Are all energy sources fitted with a cut out device?

Yes

No

Has the expansion vessel or internal air space been checked?

Yes

No

THERMAL STORES ONLY

What store temperature is achievable?

°C

What is the maximum hot water temperature?

°C

ALL INSTALLATIONS

The hot water system complies with the appropriate Building Regulations

Yes

The system has been installed and commissioned in accordance with the manufacturer’s instructions

Yes

The system controls have been demonstrated to and understood by the customer

Yes

The manufacturer’s literature, including Benchmark Checklist and Service Record, has been explained and left with the customer

Yes

Commissioning Engineer’s Signature

Customer’s Signature

(To confirm satisfactory demonstration and receipt of manufacturer’s literature)

* All installations in England and Wales must be notified to Local Authority Building Control (LABC) either directly or through a

Competent Persons Scheme. A Building Regulations Compliance Certificate will then be issued to the customer.

© Heating and Hotwater Industry Council (HHIC)

www.centralheating.co.uk

This Commissioning Checklist is to be completed in full by the competent person who commissioned the storage system as a means of

demonstrating compliance with the appropriate Building Regulations and then handed to the customer to keep for future reference.

Failure to install and commission this equipment to the manufacturer’s instructions may invalidate the warranty but does not affect statutory rights.

MAINS PRESSURE HOT WATER STORAGE SYSTEM COMMISSIONING CHECKLIST

Customer name:

Telephone number:

Address:

Cylinder Make and Model

Cylinder Serial Number

Commissioned by (PRINT NAME):

Registered Operative ID Number

Company name:

Telephone number:

Company address:

Commissioning date:

To be completed by the customer on receipt of a Building Regulations Compliance Certificate*:

Building Regulations Notification Number (if applicable)

ALL SYSTEMS PRIMARY SETTINGS

(indirect heating only)

Is the primary circuit a sealed or open vented system?

Sealed

Open

What is the maximum primary flow temperature?

°C

ALL SYSTEMS

What is the incoming static cold water pressure at the inlet to the system?

bar

Has a strainer been cleaned of installation debris (if fitted)?

Yes

No

Is the installation in a hard water area (above 200ppm)?

Yes

No

If yes, has a water scale reducer been fitted?

Yes

No

What type of scale reducer has been fitted?

What is the hot water thermostat set temperature?

°C

What is the maximum hot water flow rate at set thermostat temperature (measured at high flow outlet)?

I/min

Time and temperature controls have been fitted in compliance with Part L of the Building Regulations?

Yes

Type of control system (if applicable)

Y Plan

S Plan

Other

Is the cylinder solar (or other renewable) compatible?

Yes

No

What is the hot water temperature at the nearest outlet?

°C

All appropriate pipes have been insulated up to 1 metre or the point where they become concealed

Yes

UNVENTED SYSTEMS ONLY

Where is the pressure reducing valve situated (if fitted)?

What is the pressure reducing valve setting?

bar

Has a combined temperature and pressure relief valve and expansion valve been fitted and discharge tested?

Yes

No

The tundish and discharge pipework have been connected and terminated to Part G of the Building Regulations

Yes

Are all energy sources fitted with a cut out device?

Yes

No

Has the expansion vessel or internal air space been checked?

Yes

No

THERMAL STORES ONLY

What store temperature is achievable?

°C

What is the maximum hot water temperature?

°C

ALL INSTALLATIONS

The hot water system complies with the appropriate Building Regulations

Yes

The system has been installed and commissioned in accordance with the manufacturer’s instructions

Yes

The system controls have been demonstrated to and understood by the customer

Yes

The manufacturer’s literature, including Benchmark Checklist and Service Record, has been explained and left with the customer

Yes

Commissioning Engineer’s Signature

Customer’s Signature

(To confirm satisfactory demonstration and receipt of manufacturer’s literature)

* All installations in England and Wales must be notified to Local Authority Building Control (LABC) either directly or through a

Competent Persons Scheme. A Building Regulations Compliance Certificate will then be issued to the customer.

© Heating and Hotwater Industry Council (HHIC)

www.centralheating.co.uk

While this Checklist can be used for any installation covered by its description, only appliances manufactured by Scheme Members will

be covered by the rules and requirements of the Benchmark Scheme.

Summary of Contents for STAINLESSLITE PLUS

Page 11: ...Page 11 APPENDIX APPENDIX A ...

Page 13: ...Page 13 NOTES ...

Page 14: ...Page 14 NOTES ...

Page 15: ...Page 15 NOTES ...