Supplied By www.heating spares.co Tel. 0161 620 6677

Page 18

Page 19

SY

STEMA

TE

2000

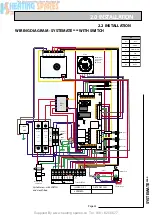

2.2 INSTALLATION

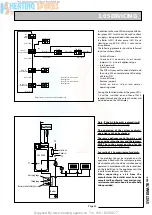

2.0 INSTALLATION

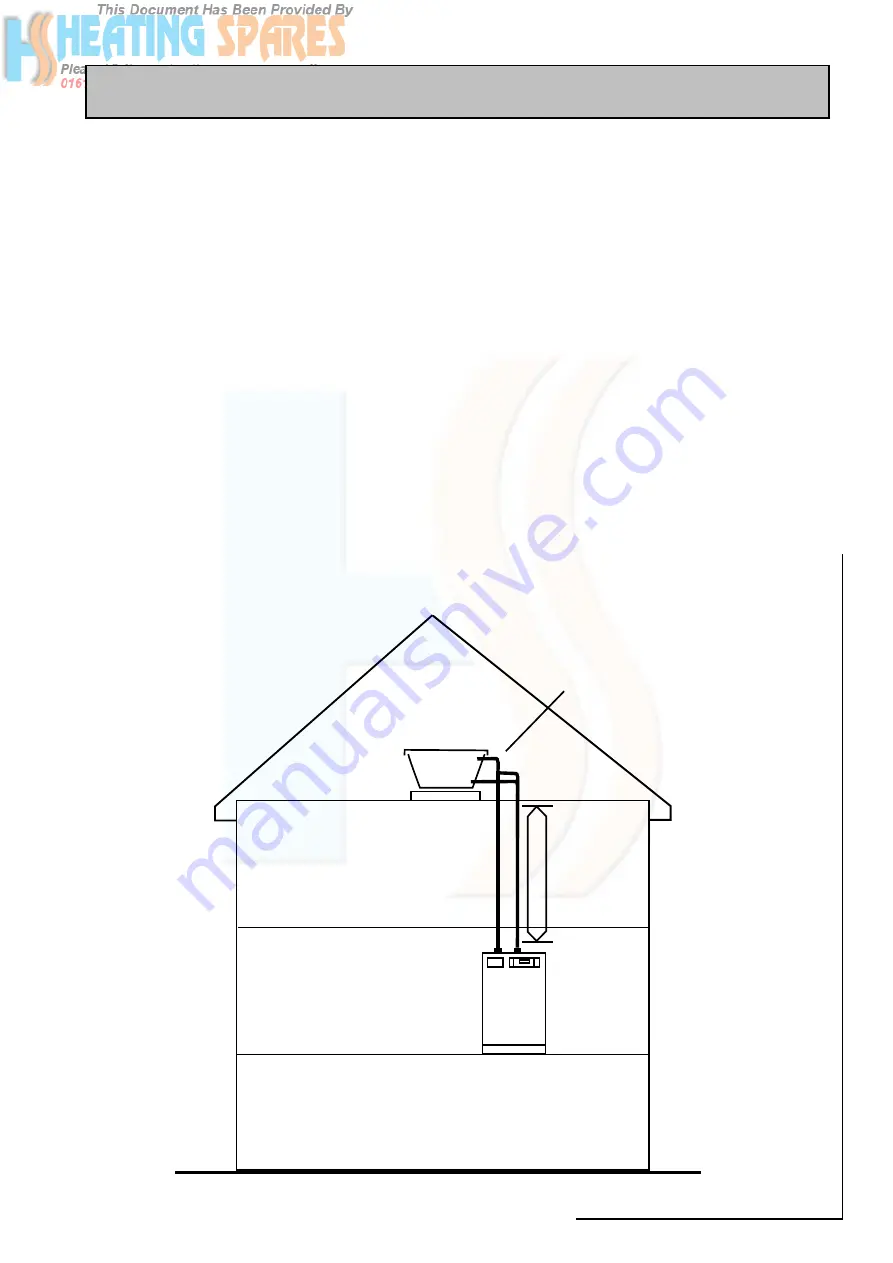

It is normally envisaged that the feed and

expansion cistern will be located in the same

cupboard as the SysteMate appliance itself to

maintain a dry roof space.

The cold feed/open vent pipework assembly

(as supplied) should be used if it is intended

to install the F & E cistern directly on top of

the appliance.

However, if it is necessary to locate the cistern

in the roof space (or on a higher floor) the

cold feed/open vent pipework assembly (as

supplied) should be used to connect to the F &

E cistern and pipework site run by the installer

to connect this to the appliance,

Obviously, any pipework in the roof space and

the feed and expansion cistern will need to

be adequately insulated to protect against

frost damage.

All factory made joints should be checked after installation in case they have

been loosened during transit.

The fittings for the feed and expansion cistern should be installed following the

instructions provided by the manufacturer in a position to suit the particular location

and the cistern fitted on its supports/base.

The cold feed/expansion and safety open vent should be installed between the

appliance and the feed and expansion cistern.

Combined feed and open vent pipe arrangements must not be used.

No valves should be fitted in the safety open vent which must be a minimum of

22mm copper pipe or equivalent.

The expansion vessel should be positioned on the supports provided and the

connecting pipe from the SysteMate 2000 connected to the air vent assembly

provided.

If an overflow/warning pipe is fitted it shall have a continuous fall, be fitted to

discharge clear of the building and be sited so that any overflow can be easily

observed. It shall also be installed in a size and material suitable for use with heating

feed and expansion cisterns in accordance with BS 5449 and should not have any

other connections to it.

���� ���� � ���� �����

�������� ��������

��� ���������

���������������

��������

��� ����������

Summary of Contents for SysteMate 125

Page 8: ...Supplied By www heating spares co Tel 0161 620 6677 Page 8 1 0 DESIGN 1 2 TECHNICAL DATA ...

Page 31: ...Supplied By www heating spares co Tel 0161 620 6677 Page 31 SYSTEMATE 2000 3 0 SERVICING ...

Page 40: ...Supplied By www heating spares co Tel 0161 620 6677 Page 40 ...

Page 41: ...Supplied By www heating spares co Tel 0161 620 6677 ...

Page 42: ...Supplied By www heating spares co Tel 0161 620 6677 ...

Page 43: ...Supplied By www heating spares co Tel 0161 620 6677 ...

Page 44: ...Supplied By www heating spares co Tel 0161 620 6677 ...