Page 10

Page 11

from any heating from the hot water pipework

to ensure that the water remains cold and of

drinking water quality.

A pipe thermostat is incorporated in the circuitry

which cuts the supply to the pump when

the water in the return pipe reaches the set

temperature. Ensure the hot water temperature

is set correctly to avoid excessively hot water at

the outlets and long pump run times.

Secondary circulation pipework must be

insulated to prevent energy loss in both heated

and unheated areas.

Immersion Heaters

These are 3kW 230V AC heaters and incorporate

a thermostat. The thermostat incorporates a

manual reset. They have incalloy elements

to prolong their life expectancy in aggressive

water conditions. We recommend best practice

of connecting the wiring to the immersion heater

is using crimp connections.

Utilising Off Peak Electricity

Where it is intended that units are fitted to

unrestricted offpeak circuits, then suitable

controllers such as the Horstmann off peak electric

time controller will be required. External wiring

to the immersion heaters must be in accordance

with the relevant IEE Wiring Regulations and the

circuit must be protected by a suitable 16A MCB

fuse and a 20A double pole isolating switch.

Safety

The immersion heaters must be earthed and they

must be isolated from the mains before the cover

is removed on every occasion. Replacement

immersion heaters should be obtained from

Gledhill Building Products Limited.

Important

The unit must not be powered up unless the

thermal store has been filled with water, the

pump has been bled and water is confirmed

to be present in the pipework above the pump.

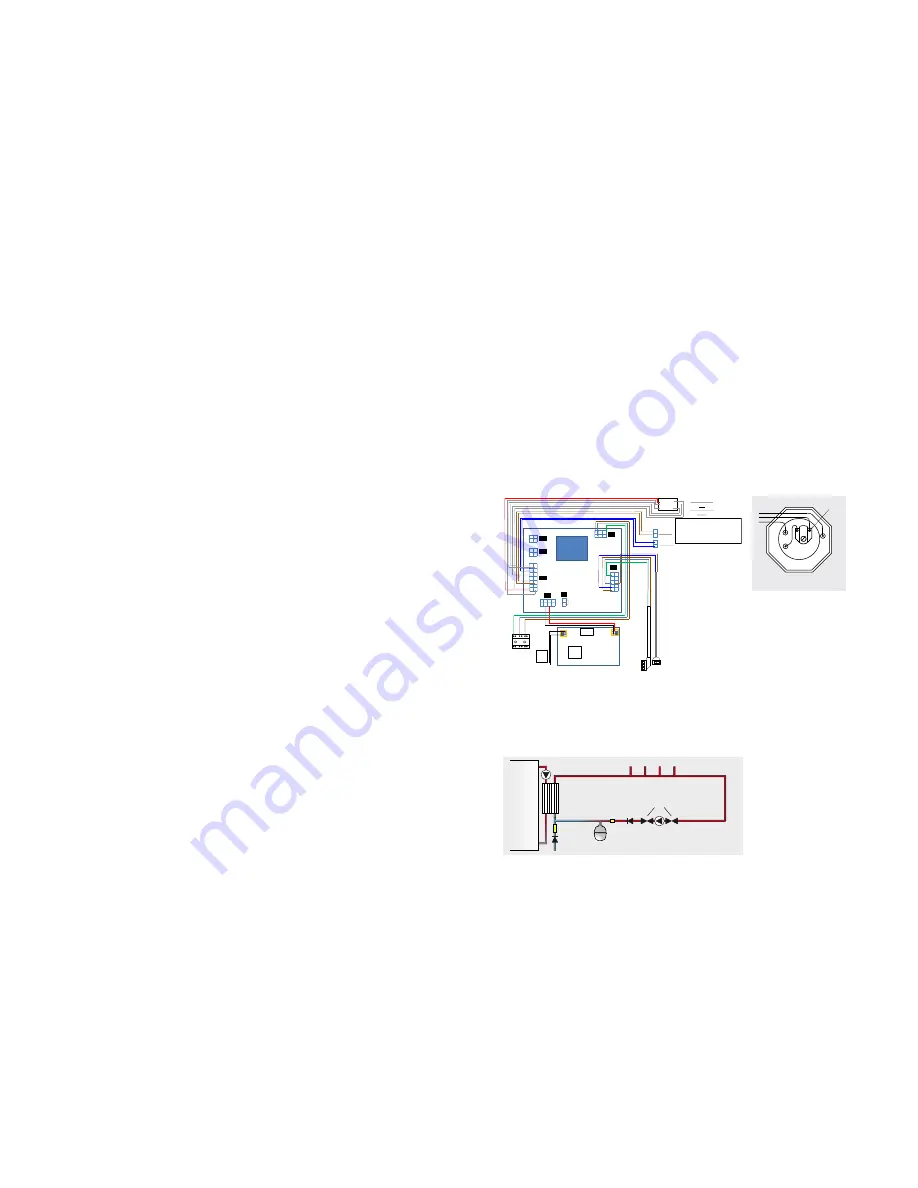

Wiring The Control Panel

The control panel requires a separate 3 amp fuse spur double pole to ensure safe

isolation. The cable/flex from the fuse spur to the control panel must be a minimum

of 0.75mm

2

C.S.A. and be heat resistant. The cable should be clipped to prevent

accidental snagging.

The control panel front cover is secured by 4 screws. Remove these and lift off the

front cover to expose the power terminals. These are found at the bottom left of the

control panel. Prepare the cable end and feed it through the cable gland.

Use a screwdriver to press the neutral cross down on the WAGO connector. This opens

the clamp and the neutral wire can be fed into the connector. Remove the screwdriver

and test the wire is securely fit. Repeat with the PE and live cables. Tighten the cable

gland and check for security. Perform the necessary safety checks and refit the front

panel.

Secondary Hot Water Circulation

If the length of the hot water draw-off pipework is excessive and the delivery time

will be more than 60 seconds before hot water is available at the tap, you may wish to

consider using trace heating to the hot water pipework such as the Raychem HWAT

system. Also a conventional pumped secondary circulation system (shown below)

can be used with any model of the Torrent Stainless.

It is important that the cold water pipework is adequately separated and protected

Pipe Layout

In all mains pressure installations it is important to remember that the incoming cold

supply must be shared between all terminal fittings. It is important that a 22mm supply

is brought to the appliance and a 22mm take-off is continued at least to the bath.

If there are two baths, 28mm pipework should be considered. One metre of smaller

diameter pipework, or flow restrictors, should be provided on the final connection to

all outlets so as to balance the water available. In any event the distribution pipework

should generally be in accordance with BS EN 806:3.

Plastic Pipework

All the recommendations with regard to the heating systems in this manual are

generally based on BS/EN Standards copper pipework and fittings. However plastic

pipework system can be used in place of copper as long as:-

a. The chosen system is recommended for use in domestic heating systems by the

manufacturers and it is installed fully in accordance with their recommendations.

b. The design criterion of the plastic system is at least equivalent to the use of BS/EN

Standards copper pipework and fittings.

c. Barrier pipework for these systems is recommended.

Ball Valve and Overflow

The feed and expansion tank can be filled manually if required e.g. using a hose pipe

fitted with a double check valve.

In this situation an overflow pipe can still be fitted if required to ensure that if a leak occurs

on the plate heat exchanger it can be discharged safely to the outside of the building.

Note: If a ball valve is fitted, then a warning/overflow pipe must always be fitted.

The feed and expansion tank (provided by the installer) must be sized correctly to

enable the expansion of the entire system volume. This will include the central heating,

store, solid fuel and boiler circuit volumes.

See page 12 for guidance sizing the feed and expansion tank.

Water Treatment

In all Torrent Stainless models, the primary (i.e. non-potable) water is stored and the

domestic hot water is heated instantaneously by means of heat exchangers. Therefore

treating the primary water will not contaminate the domestic hot water supply.

Although the Torrent Stainless primary store has no special water treatment

requirements, the radiators and other parts of the circuit will require the application of

a scale and corrosion inhibitor. The only Fernox products that arent compatible are the

Flux and to a lesser extent some of our Acidic Cleaning products, namely DS40. This is

because the Chloride in Flux can cause pitting in even Duplex Steel. The volumes and

concentration should be calculated in accordance with the manufacturers instructions

and when calculating the system volume (i.e. the water content), the volume of the

Torrent Stainless should be taken into account.

Use In Hard Water Areas And Scale Protection

The patented design of the domestic hot water plate heat exchanger is such that

the turbulence through the plates slows down the formation of scale in moderate

hard water conditions. However, the requirements set out in the ‘Domestic Building

Services Compliance Guide’ and the Building Regulations approved documents L1A

and L1B regarding scale protection should be complied with.

INSTALLATION

INSTALLATION

INSTALLATION

INSTALLATION

Thermostat

Immersion Heater Wiring

E

L

N

These requirements state that; “where the mains

water hardness exceeds 200ppm provision should

be made to treat the feed water to the water

heaters and the hot water circuit of combination

boilers to reduce the rate of accumulation of

scale”. To comply with this requirement: -

a. The hardness of the mains water should be

checked by the installer and if necessary a

suitable in-line scale inhibitor device should

specified for hardness levels between 200

and 300ppm (mg/l).

b. Where the hardness level is 300ppm (mg/l) and

above, the optional phosphate type inhibitor

should be specified and fitted at a suitable

point in the cold water supply to the appliance.

It is important that where the supply to the

Torrent Stainless is in 22mm the in-line scale

inhibitor is also 22mm. In practice servicing is not

normally required but in hard water areas, the

requirements can be considered similar to those

needed for instantaneous or ‘combi’ appliances.

The installation of scale inhibitor should be in

accordance with the manufacturers instructions

and Water Byelaws.

London Loop

As the thermal store gets hot the water will

expand and the water level in the F&E tank will

rise, as will the level of water in the vent pipe.

Hot water will also rise to the top of the cylinder.

When the water at the base of the cylinder

becomes hotter it may run out the cold feed

connection pipe. If the cold feed pipe then runs

vertically it works like a chimney with the hot

water rising to the top in the same way hot air

does from a fire. If this section is not insulated

then it will lose heat and waste energy.

If, however, the cold feed is formed into a sheppard’s

crook or london loop it will form a thermal trap. A

thermal trap works by ensuring that cold water is

held below hot water. Because hot water always

rises it will not be able to move down and around

the loop/crook and therefore will not rise up the

cold feed pipe work. This will reduce heat loss and

thereby prevent energy waste.

The minimum depth of the U trap is calculated by

multiplying the pipe diameter by 8. For example;

• Using 22mm pipework will require a

minimum of 176mm

22mm pipework is highly recommended to

ensure that the London loop does not air lock

during the commissioning process. It also

enables a faster installation of the product due

to the increased filling rate.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

1

2

3

4

1

2

3

4

1

2

3

4

5

6

7

8

1

2

1

2

3

4

5

6

7

8

9

1

10

2 3

4 5 6

J18

J20

J19

J3

J7

J8

J1

TS sensor

GND GND

IN OUT

T1 T2

1

2

CW sensor

1

2

Combined flow

and

HW temperature

sensor

L - Brown

PR61

E – G/Y

N - Blue

PW

M

-

PW

M

+

SP

ARE

Fuse

Dip

Sw

itc

h

1 2 3 4

To

DHW

pipe

All the these sensor inputs carry a

Voltage of 5V.

The max cable length is 1 meter.

The sensors connected to the control

Should be free from the appliance earth

Torrent Stainless

Inline filter &

flow regulator

Single check

valve

Single

check

valve

Pump isolation

valves

Cold water inlet

Plate heat exchanger

Hot water outlets

Pipework length and

diameter to suit

property demands

Pipework length and

diameter to suit

recirculation flow rate

approx 1-2 l/min

Cold water sensor

Control

stat

Flow sensor

Potable water

expansion vessel

Secondary

circulation

pump

Summary of Contents for Torrent Stainless OV

Page 22: ...Page 42 Page 43 NOTES NOTES ...