LIT-181

Page 2 of 4

Square Gravers in Quick

Change holders (FIG. F), must

be inserted into the jaws from

the back. DO NOT hold tool by

the Quick Change holder in the

jaw.

Hold Curved Traditional

Graver (FIG. G) as shown.

NOTE: Because of the

tools curve, you will need to

guesstimate the angle needed

to set the face angle.

90 DEGREE SQUARE GRAVER

With the graver’s excess metal

removed (see getting the graver

ready to sharpen, (FIG. G-1)

you are ready to make the face

angle (FIG. G-2). With the tool

mounted, face angle down, and

the TOOL DIAL locked at 0°, set

the POST DIAL at 45°. This is

just an example, you may change

face angles to fit your needs. If

you are using a square blank

graver, start your face angle by

using a 260 grit wheel on the

Power Hone. Then finish the face

surface by stepping up to a 600

grit, then a 1200 grit. Once you

have finished the face you will

need only to take these steps

again if the tip becomes severely

damaged. If you’re not using a

Power Hone, shape the face as

close as possible on a bench

grinder and finish with this fixture

and a stone.

A 15° heel will be used for this

example (FIG. G-3 & 4). Set the

POST DIAL at 15° and lock it.

Rotate the TOOL DIAL halfway

around or 180°, go from the top

0° setting until the bottom 0°

setting is on top. From the new

0°, tool pointing away from

you, turn dial clockwise, until

it reads 45° and lock. Sharpen

on a ceramic wheel making the

heel about 1/32" long. If you

heel on a 1200 grit wheel, use

the fixture and stroke the graver

a couple times without turning

the Power Hone on. After

forming this heel turn the dial

counterclockwise going past the

0° until it reads 45° and lock in

position. Finish the heel on this

side using the same method. It

is important that both heels are

the same size and symmetrical.

MAKING A 120 DEGREE GRAVER FROM A SQUARE GRAVER

Refer to “SHARPENING A 90° GRAVER”, for details. With the

graver’s excess metal removed (FIG. H-1) mount the tool face

angle down in the TOOL DIAL

and lock at 0°. Set the

POST DIAL at 45° (or desired

face angle) and grind the face

(FIG. H-2). Turning the TOOL

DIAL around 180° to reference

0° and change the POST DIAL

to 2-1/2° (halfway between 0°

and 5°) and lock in position.

From reference 0°, rotate dial

clockwise to 30° and grind angle

(FIG. H-3). Make this angle

grind about 1/2" long. Rotate

TOOL DIAL counter clockwise

past reference 0° to 30°, lock

and grind angle (FIG. H-4).

Make this side the same length

as the other side (FIG. H-3).

TIP: To measure how much you

are grinding off, time it or count

while it’s grinding. It may be

necessary to regrind the other

side to make both sides equal.

But it is important that the sides

are equal and symmetrical.

Make the heel (FIG. H-5 & 6)

by changing the POST DIAL

to 15° (or desired heel angle).

The TOOL DIAL is already at

30° left, so make this heel and

rotate TOOL DIAL right, past

reference 0° to 30° and make

the other heel. The 120° graver

is complete.

HOW TO MAKE A 110 DEGREE

& 130 DEGREE OUT OF A

SQUARE GRAVER

Basically, making a 110° or

130° graver is the same as

making a 120° graver, just

change the TOOL DIAL angle

for different side angles.

110° graver (FIG. H-3, 4): The side angle POST DIAL is set at

2-1/2°, but set the TOOL DIAL from reference 0° left 35° and make

one side, then right 35° from reference 0° to make the other side.

130° graver (FIG. H-3, 4): The side angle POST DIAL is set at

2-1/2°, but set the TOOL DIAL from reference 0° left 25° and make

one side, then right 25° from reference 0° to make the other side.

How do you figure this angle setting? The sides of a 90° tool

mounted in a fixture, dial set at 0°, are 45° from the wheel. Adding

all angles: 45° + 45° + 90° = 180° (a flat plane). Using 180° minus

(desired tool angle) let’s say, 110° = 70°. There are two sides to

the tool, so you divide 70° by 2 which equals 35°, the setting to

make a 110° graver.

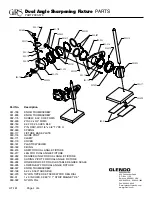

FIG. F

FIG. H

FIG. G-2

Face Angle

FIG. G-3&4

HEEL

FIG. G

FIG. H-2

Face Angle

FIG. H-3, 4

Heel

FIG. H-5&6

Heel