Glentek Inc. 208 Standard Street, El Segundo, California 90245, U.S.A. (310) 322-3026

16

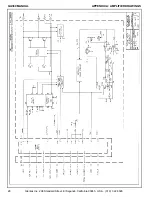

GA369 MANUAL

CHAPTER 6: START UP AND ADJUSTMENT PROCEDURE

CHAPTER SIX: START UP AND ADJUSTMENT PROCEDURE

6.1 SAFETY PRECAUTIONS:

Before starting the adjustment and alignment procedure please be sure to observe

the following precautions:

1. Be

certain that there are no visibly loose or damaged components.

2. Check that all connections are tight.

3. Check all power and signal wiring. Remove power input fuses, apply power and measure that correct power

voltage is being applied. Your DC Buss voltage will be 1.4 x the AC power applied (Refer to Appendix A, note 1).

4. Be sure that the motor mechanism is clear of all obstructions. If motor is connected to an axis lead screw or other

device with limited motion, place at midposition.

5. Work on only one amplifier at a time.

6. Make sure all Loop Gain pots are turned fully CCW before applying power.

7.

DO NOT

use grounded test equipment.

6.2 AMPLIFIER ALIGNMENT INTRODUCTION:

When adjusting an amplifier for optimum velocity loop operation it is desirable to achieve a critically damped, stable

step velocity response with maximum DC Tach Gain. The following discussion will describe how to best achieve this

result:

Your amplifier has been run at the factory with a known motor, tachometer and inertial load. In testing at the factory

we try to simulate the same conditions you will have in your system. For this reason it is a good idea to start with the

initial settings as shipped from the factory.

NOTE:

All of the following adjustments are to be made on the Personality Preamp card (Refer to Appendix

C, drawings 369-1200 & 369-1202).

6.3 VELOCITY LOOP PHASING:

For proper servo operation it is necessary for the amplifier to receive negative feedback from the tachometer. If the

tachometer leads are reversed (positive feedback), the amplifier will run away. To check the phasing of the motor and

tachometer proceed as follows:

1. Make sure Loop Gain potentiometer, R59, is full CCW (as shipped from factory).

2. Make sure that nothing is connected to the Signal Input (J1-3) or the Auxiliary Signal Input (J1-1 or J1-2).

3. Apply the main power.

4. Slowly turn the Loop Gain potentiometer, R59, CW. If the motor starts to run away turn the Loop Gain potenti-

ometer full CCW and reverse the motor armature leads. Again, turn the Loop Gain potentiometer CW. The motor

should be stopped or rotating slowly.

5. Leave Loop Gain potentiometer, R59, full CW for all remaining adjustments and operations.

6.4 TACH GAIN ADJUSTMENT:

1. At this point the motor will be rotating slowly. Adjust the Balance potentiometer,R43, until the motor rotation is

stopped.

2. While observing the tachometer output voltage with an oscilloscope, apply a step input voltage at the Signal Input

terminal of the amplifier. A step input voltage can be simulated by applying and removing a flashlight battery to

the Signal Input. For this purpose the battery is usually mounted inside of a small box with a switch. Common

names used to describe this DC signal voltage source are Battery Box or DC Simulator. Elaborate signal sources

are often made for this purpose including bipolar output, potentiometer output adjust and polarity reversing

switches, etc. You often hear the term

“DC Box the velocity loop

servo”

being used by people working on servo

systems.

(This Signal Box may be purchased from Glentek Inc., Part Number BB700)