17

q

15) With your engine still installed on the mo-

tor mount beams, use a ruler and measure the width

between the predrilled mounting holes in the motor

mount. This distance will vary depending on the

brand and size of the engine you have chosen. See

photo # 32 below.

q

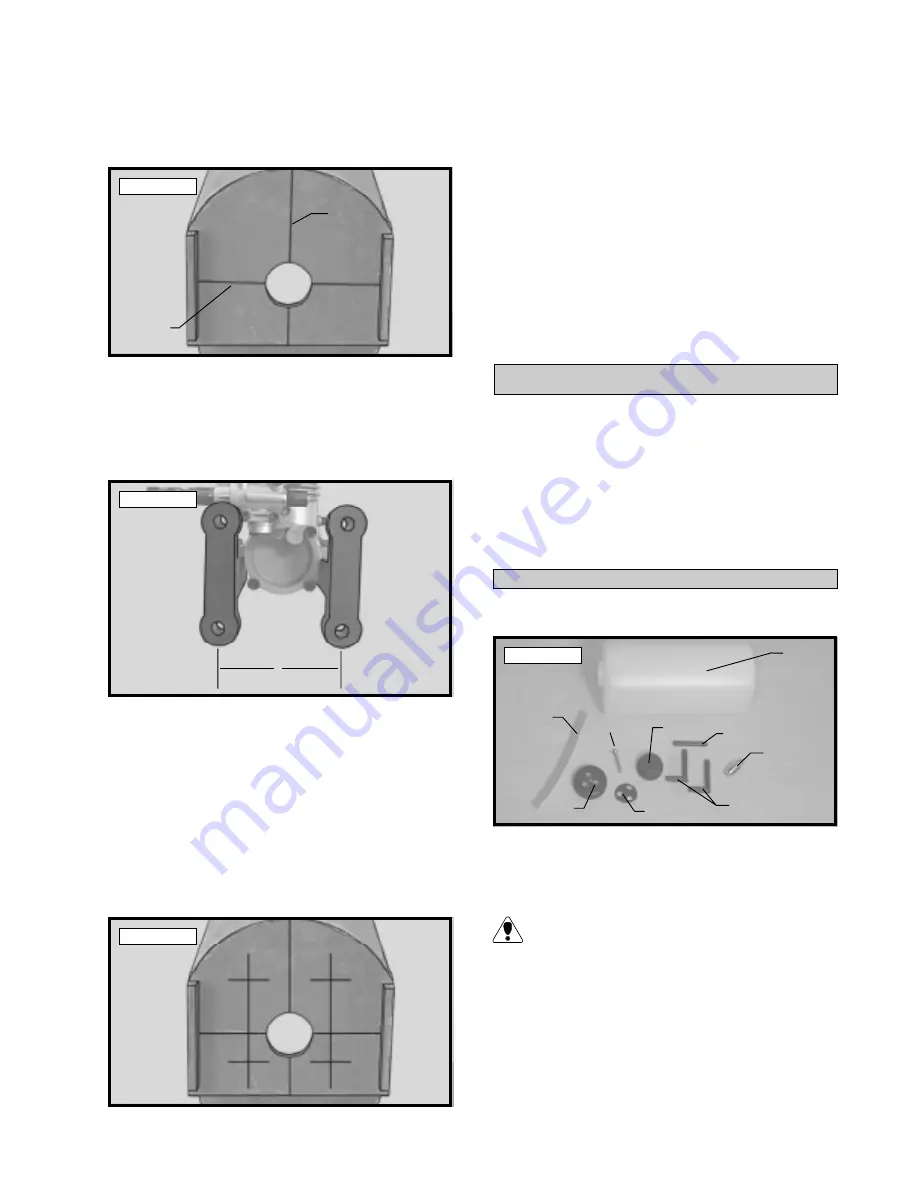

14) Using a ruler and a pen, measure up from

the bottom of the firewall 1-1/2” and place two

marks. Draw a horizontal line at these two marks.

See photo # 31 below.

Photo # 31

q

16) Divide the measurement found in step # 15

in half. Measure and mark this resulting distanceand

place marks to the right and left of the vertical center-

line. Draw one vertical line at the marks made to the

right and left of the vertical centerline.

q

17) On the two vertical lines you just drew,

measure and place two marks 5/8” below the hori-

zontal centerline and two marks 1-1/16” above the

horizontal centerline (looking at the firewall). See

photo # 33 below.

Photo # 32

q

18) Hold the motor mount assembly up to the

firewall and double check that the four intersecting

lines line up with the four predrilled holes in the mo-

tor mount beams.

q

19) Using a 7/32” drill bit, drill the four mount-

ing holes through the firewall for the motor mount

beams.

q

20) Mount the motor mount assembly to the fire-

wall using the four 4mm x 20mm machine screws,

four 4mm flat washers and four 4mm blind nuts.

Tighten the screws securely to draw the blind nuts

into the back of the firewall completely.

Photo # 33

PARTS REQUIRED

q

{1} 280cc Molded Fuel Tank

q

{1} 4mm x 28mm Nylon Pick-Up Tube

q

{2} 4mm x 28mm Prebent Nylon Vent Tube

q

{1} 3mm x 18mm Self Tapping Screw

q

{1} Length of Fuel Tubing

q

{1} Metal Weighted Pick-Up

q

{1) Nylon Fuel Cap

q

{1} Rubber Stopper

q

{1} Nylon Backplate

FUEL TANK

STOPPER ASSEMBLY

q

2) Using a modeling knife, cut the silicon fuel

tubing to 3-3/4” long. Connect one end of the tubing

to the weighted pick-up.

There are three molded holes in the rubber fuel

tank stopper. Two are opened and one is cov-

ered by a thin layer of rubber on the front of the stop-

per. Using a modeling knife, remove the thin layer of

rubber to completely open the third hole.

q

3) Push the single 4mm x 28mm nylon pickup

tube through one hole in the rubber stopper until 3/8”

protrudes from the front of the stopper. Slide the ny-

lon backplate over the tube at the back of the stopper.

q

1) Identify each of the parts that make up the

fuel tank assembly. See photo # 34 below.

Photo # 34

Vertical

Centerline

Horizontal

Centerline

Tank

Clunk

Silicon

Tube

Rubber

Stopper

Backplate

Screw

Pickup

Tube

Vent

Tubes

Cap

X

X = Distance

Between Beam

Mounting Holes