21

q

7) Using wire cutters, cut the length of wire cable

exactly in half. If the wire begins to unravel, care-

fully twist the wire back into shape and apply a drop

of Kwik Bond Thin C/A to the end of the wire.

q

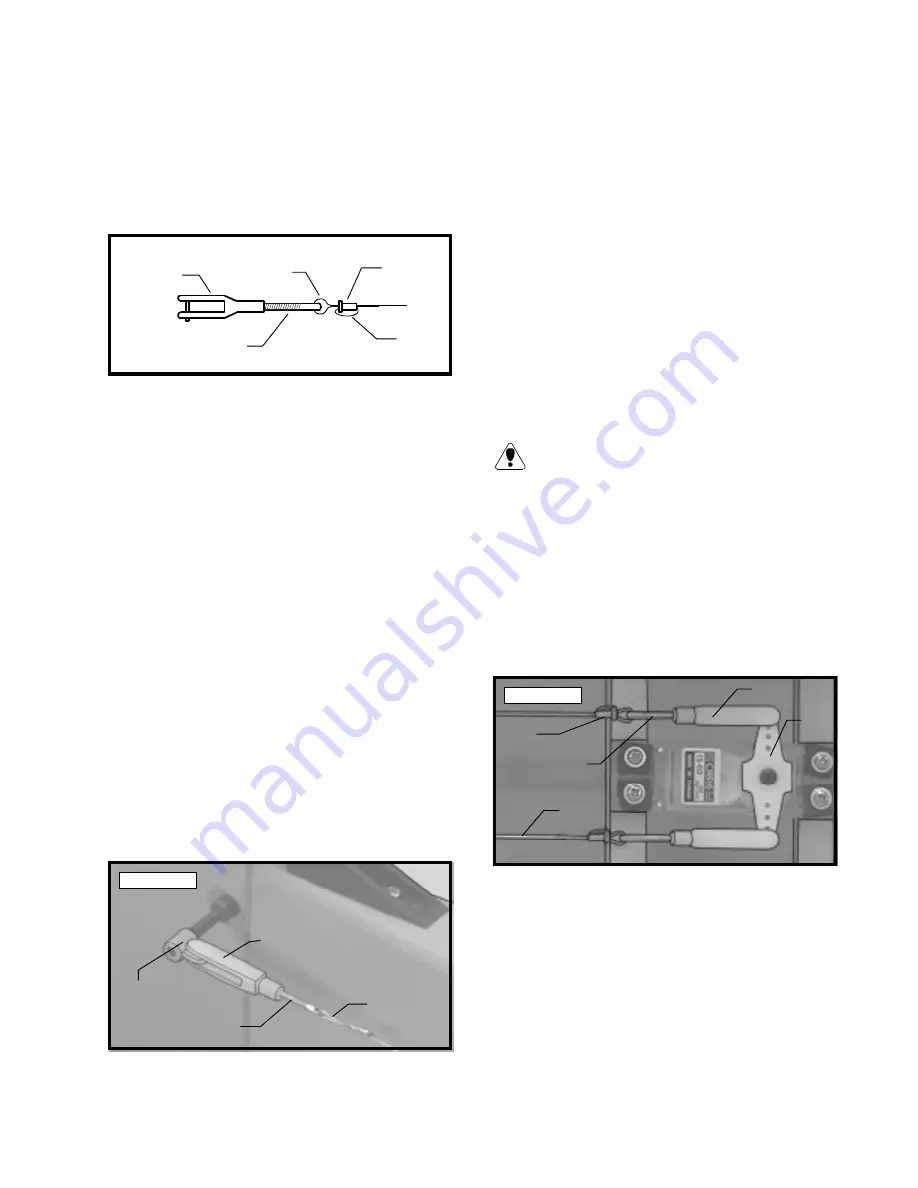

8) Install one threaded coupler onto only one

end of each wire cable. See figure # 17 and steps

A - D below.

Figure # 17

q

A) Slide one crimp collet onto the cable,

non-flange side first.

q

B) Thread one end of the cable through the

predrilled hole in the end of the threaded coupler,

then thread the cable back into the crimp collet.

q

C) Loop the cable around and thread it back

through the crimp collet. Pull the cable tight to

eliminate the slack in the loop.

q

D) Squeeze the crimp collet with pliers to

secure the cable in place. Apply a couple of drops

of Kwik Bond Thin C/A to the collet to lock it in

place. After the glue has cured, pull on the cable

to ensure the crimp collet is secure.

q

9) Thread one nylon clevis onto each of the two

threaded couplers. For security thread the clevises

on no less than 5/16”.

q

10) Attach one clevis to each adjustable control

horn and thread the other end of the cable through the

exit slots in the sides of the fuselage and into the servo

compartment. See photo # 41 below.

Photo # 41

q

12) Thread two nylon clevises onto the two re-

maining threaded couplers. For security, thread the

clevises on no less than 5/16”.

q

13) Hold the rudder in neutral using a couple of

pieces of masking tape. Plug the rudder servo into

the receiver and center the servo. The servo arm

should be perpendicular to the fuselage sides.

q

14) Working with the right side first, install one

nylon clevis/threaded coupler assembly into the outer

hole in the servo arm.

q

15) Slide one crimp collet, non-flange side first,

over the length of cable on the right side. Thread the

cable through the predrilled hole in the threaded cou-

pler.

Make sure the two cables do not cross inside

the fuselage. The cable from the right side of

the rudder should attach to the right side of the servo

arm.

q

16) While keeping the rudder and the rudder

servo centered, pull the cable tight and secure it in

place using the same technique as previously. Re-

move the excess cable using wire cutters.

q

17) Repeat steps # 14 - # 16 for the opposite

cable. See photo # 42 below.

Photo # 42

q

18) Remove the masking tape from the rudder.

With you radio system turned on and the rudder servo

and rudder centered, check for slack in the cables.

They should be fairly tight. Move the rudder to one

side, then let go of the stick. The rudder should come

back to center. Do this a couple of times in each di-

rection. If the rudder does not come back to center,

the cables are too tight. You can change the tension

of the cables by adjusting the clevises. For best re-

sults, you want the cables to be as tight as possible,

but not so tight that the linkage binds or does not cen-

ter when the rudder goes to neutral.

q

11) Install a long dual-arm servo arm onto the

rudder servo. Use wire cutters to remove the excess

arms.

Clevis

Threaded

Coupler

Wire

Cable

Crimp

Collet

Loop

Adjustable

Control

Horn

Clevis

Threaded

Coupler

Cable

Cable

Clevis

Servo

Arm

Threaded

Coupler

Crimp

Collet