22

PARTS REQUIRED

q

{1} 740mm Split Elevator Pushrod Assembly

q

{2} Nylon Clevises

q

{1} Adjustable Servo Connector Assembly

q

{2} Nylon Control Horn w/Backplates

q

{4} 2mm x 25mm Machine Screws

ELEVATOR PUSHROD

INSTALLING THE CONTROL HORNS

q

1) Position one elevator control horn on the bot-

tom of each elevator half. The centerline of each

horn should be 5/8” out from the fuselage sides at

the hinge line. Position the control horns so the cle-

vis attachment holes are directly in-line with the

hinge lines. The control horns should be angled to-

wards the fuselage sides. See figure # 18 below.

q

2) When satisfied with the alignment, use a

3/32” drill bit, and the control horns as a guide, and

drill the mounting holes through the elevator halves.

q

3) Mount the control horns to the elevators by

inserting the four 2mm x 25mm machine screws

through the control horn mounting bases, through the

elevator halves and into the backplates. Tighten the

screws, but do not overtighten them. You do not want

to crush the wood.

Figure # 18

q

4) Using a modeling knife, remove the cover-

ing from over the two elevator pushrod exit slots in

the rear of the fuselage. The center of each slot is

located on each side of the fuselage, 4” in front of the

rudder hinge line and 1” below the horizontal stabi-

lizer. Each slot is 1-1/2” long and 3/16” tall.

q

5) Slide the elevator pushrod assembly through

the fuselage and out the two pushrod exit holes. To

make this easier, drop two pieces of string through

the exit holes and into the servo bay. Tie one piece of

string to each wire and carefully pull the string. This

will guide the pushrod wires out the exit holes.

INSTALLING THE ELEVATOR PUSHROD

Make sure that when you install the pushrod, it

is installed below the rudder cables and that the

cables do not get wrapped around the pushrod wires

or dowel.

q

6) Thread two nylon clevises onto the threaded

ends of both elevator pushrods. For security, thread

the clevises on no less than 5/16”.

q

7) Attach each clevis to the outermost hole in

each control horn. See photo # 43 below.

Photo # 43

q

8) Install one adjustable servo connector through

the fourth hole out from the center of one servo arm.

You may have to enlarge the hole in the servo arm to

accommodate the servo connector. Remove the ex-

cess material from the arm. See figure # 19 below.

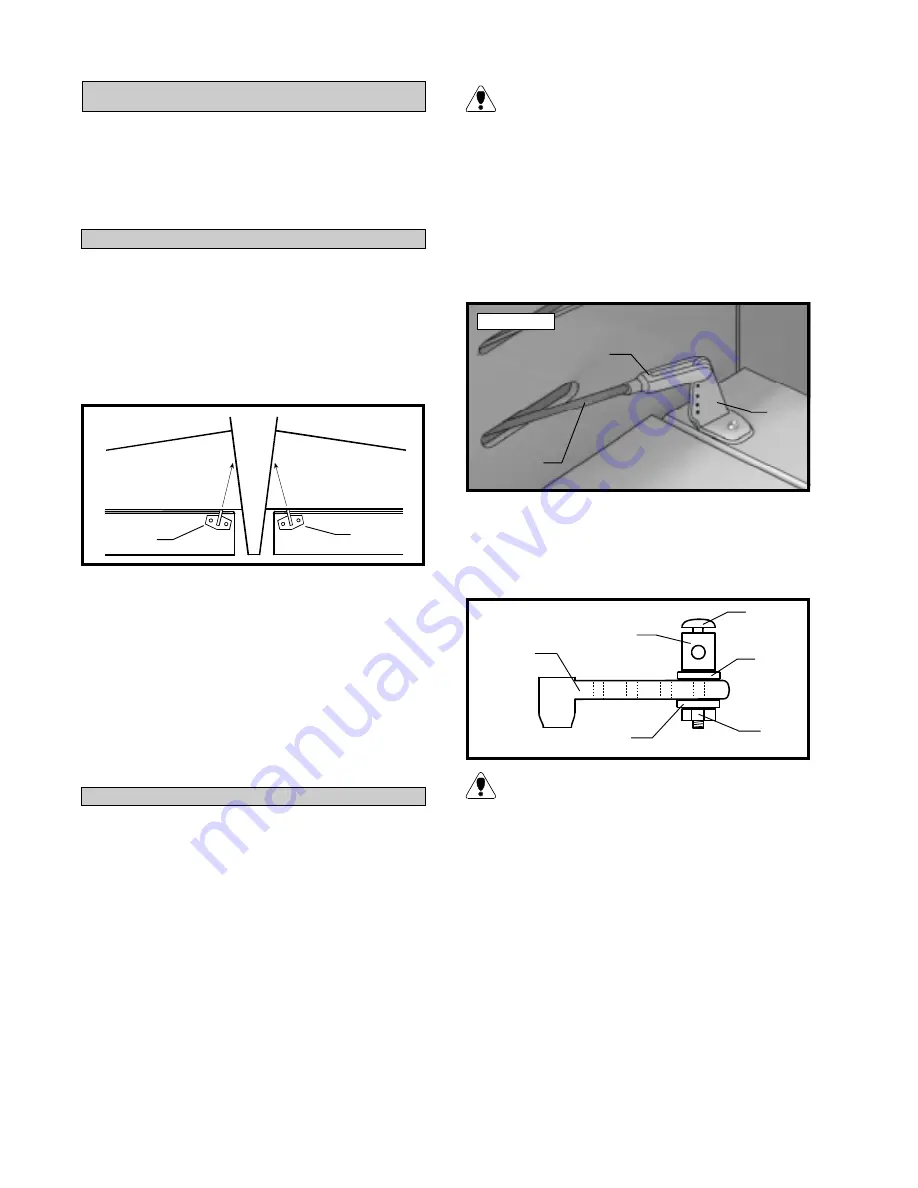

Figure # 19

After installing the adjustable servo connector

apply a small drop of Kwik Bond thin C/A to

the nut. This will prevent the connector from loosen-

ing during flight.

q

9) Slide the elevator pushrod wire through the

hole in the adjustable connector.

q

10) Use a couple of pieces of masking tape to

hold each elevator half in neutral.

q

11) Plug the elevator servo into the receiver and

center the servo. Place the servo arm onto the servo.

The servo arm should be perpendicular to the fuselage

sides and point towards the middle of the fuselage.

Pushrod

Wire

Clevis

Control

Horn

Servo

Arm

Set

Screw

Servo

Connector

Washer

Washer

Nut

Control

Horn

Control

Horn