7

The heat shrink tubing will prevent the plugs

from coming apart during assembly and more

importantly during flight. If you don't use heat shrink

tubing, electrical tape works well also.

q

19) Using the throttle pushrod wire as a guide,

insert one end through the precut servo lead hole in

the root rib, through the center ribs and into the servo

bay in the middle of the wing. Using masking tape,

tape the servo lead to the end of the wire. Carefully

pull the wire out of the wing while guiding the servo

lead out. When you have pulled the servo lead out,

remove it and the masking tape from the wire.

q

20) Set the servo hatch in place on the bottom

of the wing. The hatch should be orientated with the

servo arm toward the wing tip and up towards the

leading edge.

q

21) Using a ruler and a pen, measure and mark

the four mounting hole locations onto the hatch. The

holes should be located 1/8” in from each edge.

q

22) Drill 5/64” pilot holes through the hatch and

into the hardwood blocks beneath it at the locations

marked. Be careful not to drill through the top of the

wing! Remove the hatch and enlarge the holes in

only the hatch using a 7/64” drill bit. Reinstall the

hatch using the four 2.5mm x 12mm wood screws.

See photo # 3 below.

Photo # 3

q

23) Repeat steps # 17 - # 22 for the second servo

hatch assembly.

INSTALLING THE DIHEDRAL BRACE

q

24) Look at the surface of each root rib on both

wing halves. Notice how the excess covering mate-

rial overlaps onto them. Using a modeling knife, care-

fully cut away the covering from both of the root ribs.

Leave about 1/16” of covering overlapping so it does

not pull away.

It is important that the covering be removed

from the root ribs. This will ensure an adequate

wood-to-wood glue joint and prevent wing failure

during flight.

q

25) Using a ruler and a pen, locate and mark

the centerline of the plywood dihedral brace. Draw

one vertical line at this location on each side. See

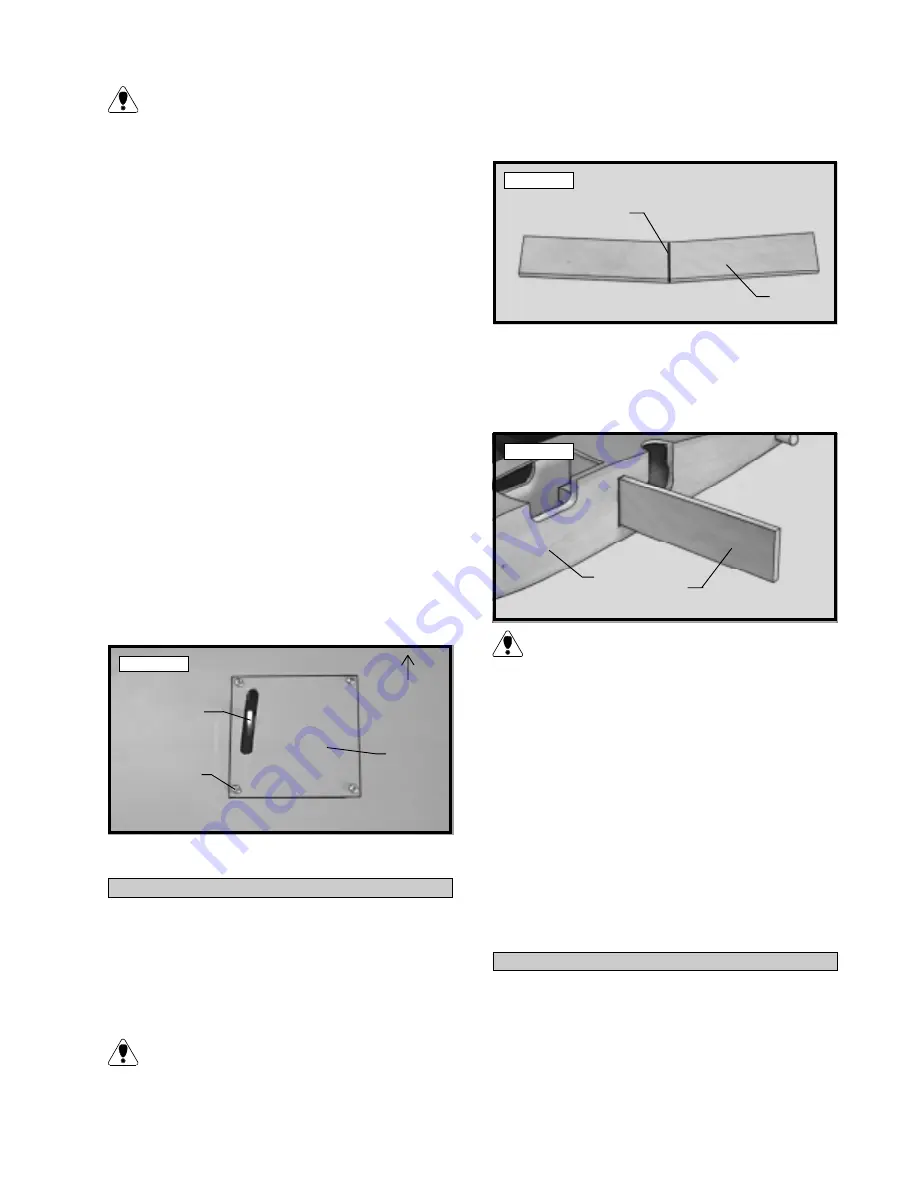

photo # 4 below.

Photo # 4

q

26) Test fit the dihedral brace into the plywood

box in each wing half. The brace should slide into

each wing half up to the centerline. If it does not,

remove the brace and lightly sand the edges and tips

until the proper fit is obtained. See photo # 5 below.

Photo # 5

The dihedral brace is cut in the shape of a "V".

The "V" shape should face the top surface of

the wing when the brace is installed.

q

27) Test fit both of the wing halves together with

the dihedral brace temporarily installed. Do not use

glue at this time! The wing halves should fit to-

gether tight with little or no gaps in the center section

joint. If the center section joint is not tight, remove

the wing halves and lightly sand the edges and tips of

the dihedral brace. Test fit the wing halves together

with the dihedral brace installed again. Repeat until

you are satisfied with the fit of the wing halves.

q

28) When satisfied with the fit of the wing

halves, remove the wing halves and the dihedral brace.

q

29) Mix a generous amount of Kwik Bond 30

Minute Epoxy. Working with only one wing half for

now, apply a thin layer of epoxy inside the plywood

dihedral brace box and to only half of the dihedral

brace. Make sure to cover the top and bottom as well

as the sides, and use enough epoxy to fill any gaps.

JOINING THE WING HALVES

Servo

Hatch

Servo

Arm

Leading

Edge

Wood

Screw

Dihedral

Brace

Draw

Centerline

Dihedral

Brace

Root

Rib