9

PARTS REQUIRED

OPTIONAL RETRACT MAIN GEAR

INSTALLING THE RETRACT MECHANISMS

q

{2} 50mm Diameter Wheels

q

{2} Molded Plastic Retract Gear Covers

q

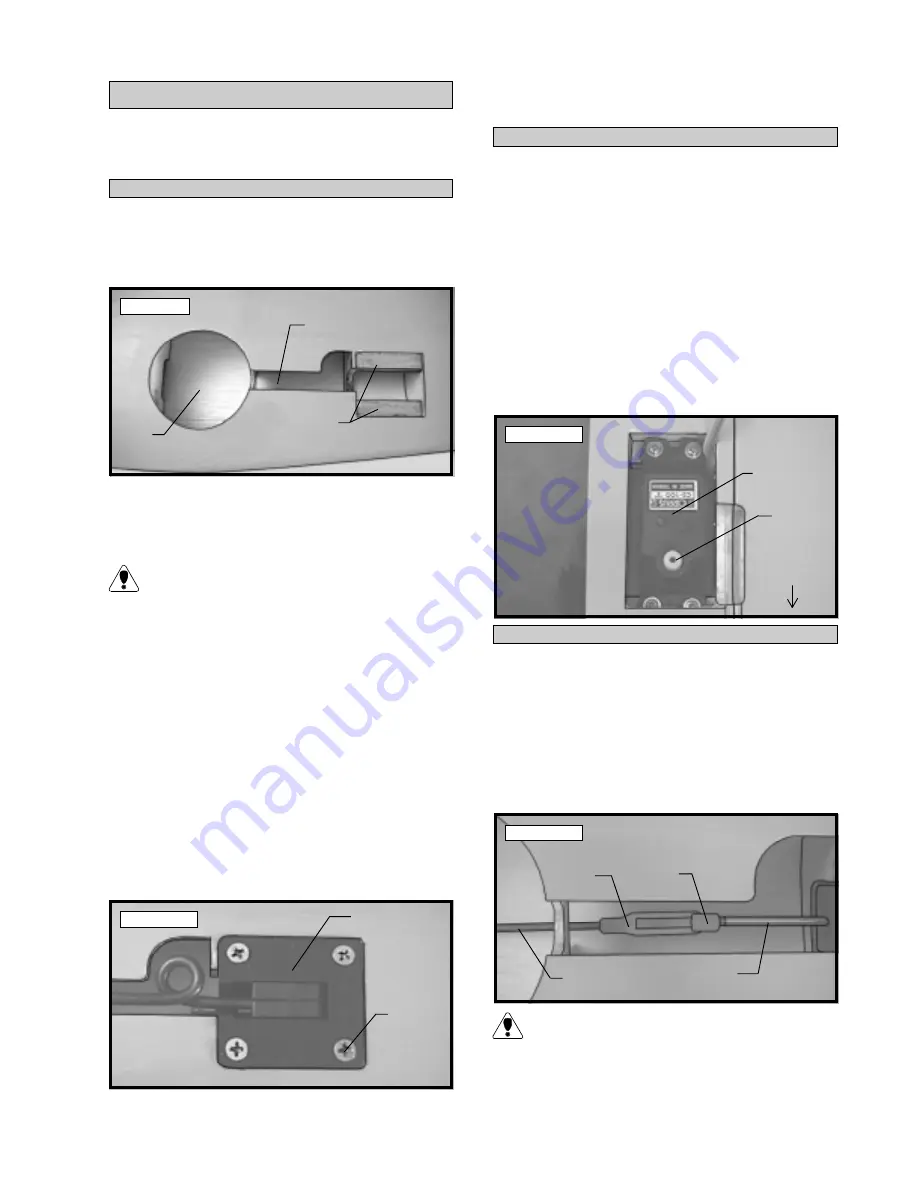

1) Using a modeling knife, remove the cover-

ing from over the two sets of precut wheel wells, gear

strut channels and retract mounting blocks in the bot-

tom of the wing. See photo # 9 below.

Photo # 9

q

2) Working with one wing half at a time, trial

fit the retract mechanism onto the hardwood mount-

ing rails.

The spacing between the two hardwood rails

should be sufficient for most popular brands of

retracts. If your retract mechanism is wider, you will

need to trim equal amounts of material off of the in-

side edge of each hardwood rail. If this is necessary,

we recommend using a Dremel Tool with a sanding

drum attachment.

q

3) When satisfied with the fit of the mechanism,

install the retract onto the rails. Drill 5/64” pilot holes

through the rails to prevent the wood from splitting

when you install the mounting screws. Be careful

not to drill through the top of the wing!

q

4) Install the retract using the mounting screws

provided with the retract. Tighten the screws com-

pletely. See photo # 10 below.

Photo # 10

q

5) Repeat steps # 2 - # 4 for installing the sec-

ond retract mechanism.

INSTALLING THE RETRACT SERVO

q

6) Install the rubber isolation grommets and

brass collets onto your retract servo. Place the servo

onto the preinstalled rails in the servo compartment

in the top of the wing. The servo output shaft should

face the leading edge of the wing.

q

7) Using a 1/16” drill bit, drill pilot holes through

the rails for the mounting screws. Be careful not to

drill through the bottom of the wing!

q

8) Secure the servo in place on the rails using

the mounting screws provided with the servo. See

photo # 11 below.

Photo # 11

INSTALLING THE RETRACT LINKAGE

q

9) Using wire cutters, cut both 12” 2-56 threaded

rods (not included) to 5” long. Thread one nylon cle-

vis (not included) onto each of the two rods.

q

10) Slide the two threaded rods, with the clev-

ises attached, through the precut slots in the ribs, up

to the retract mechanism. Snap the clevises onto the

adjustable control horns. See photo # 12 below.

Photo # 12

The easiest way to get the threaded rods through

the slots is to insert the clevis end first through

the retract servo opening. They will slide through the

slots, up to the retract mechanism without any bend-

ing necessary.

Wheel

Well

Strut

Channel

Mounting

Blocks

Retract

Servo

Output

Shaft

Leading

Edgle

Pushrod

Wire

Nylon

Clevis

Adjustable

Control

Horn

Retract

Arm

Retract

Mechanism

Mounting

Screw

(not included)