5

Need help or have any questions? Call us at 1-714-963-0329 or send us an Email at service@globalhobby.net

SECTION 3: ASSEMBLING YOUR X-TERMINATOR PRO

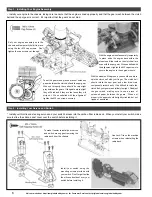

Step 1: Installing the Clutch Assembly

●

Install the flywheel, clutch shoes, clutch springs and clutch bell assembly onto your engine.

●

Temporarily install the M3 cap screw and lock nuts onto your engine mounting lugs in preparation for installing the engine.

Before installing the clutch bell, lightly sand the inside

surface of the clutch bell, using 600 grit sandpaper ,

then clean it thoroughly, using rubbing alcohol.

Doing this will allow the clutch shoes to "bite" better,

reducing clutch slipping.

For now, only partially thread the lock

nuts onto the cap screws.

Install the flywheel and the

clutch nut before installing the

clutch shoes and springs.

Tighten the clutch nut firmly.

Place the clutch shoes, with the clutch

springs, over the three pins on the flywheel.

Using a small screwdriver as a lever, bend

the short end of each clutch spring behind

the clutch nut and push the clutch shoes

down to snap them into place.

Take your time when installing the clutch shoes and springs. This

is a high-performance clutch with very stiff springs. Patience is

necessary to get it installed properly. After installing the clutch

bell, make sure it spins freely. It should not drag over the clutch shoes.

*Note the direction the clutch shoes are installed.

Make sure that the long portion

of the clutch springs fit firmly in

the groove in the clutch shoes.

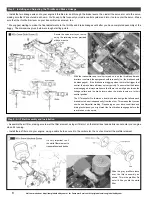

Step 2: Installing the Engine Mounts & Exhaust Header

●

Temporarily slide the two aluminum engine mounts over the M3 lock nuts.

●

Install the exhaust header onto your engine, using the exhaust hanger spring and retainer bracket to hold it in place.

The retainer spring connects

to the retainer bracket and

wraps around the engine to

hold the exhaust header

firmly in place.

The exhaust header fits most .21 size round-port,

rear exhaust engines. If you're using a side exhaust

engine, after-market headers are available.

The flat sides of the hex nuts must line up with the

channel in the engine mounts, so that the engine

mounts can be slid into position. Do not tighten the

cap screws yet.