8

Combination Sander

ADJUSTMENTS AND TOOLS

ADJUSTMENTS AND TOOLS

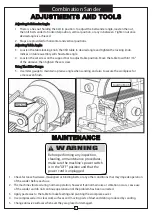

Adjusting Belt Sander Angle:

Adjusting Belt Sander Angle:

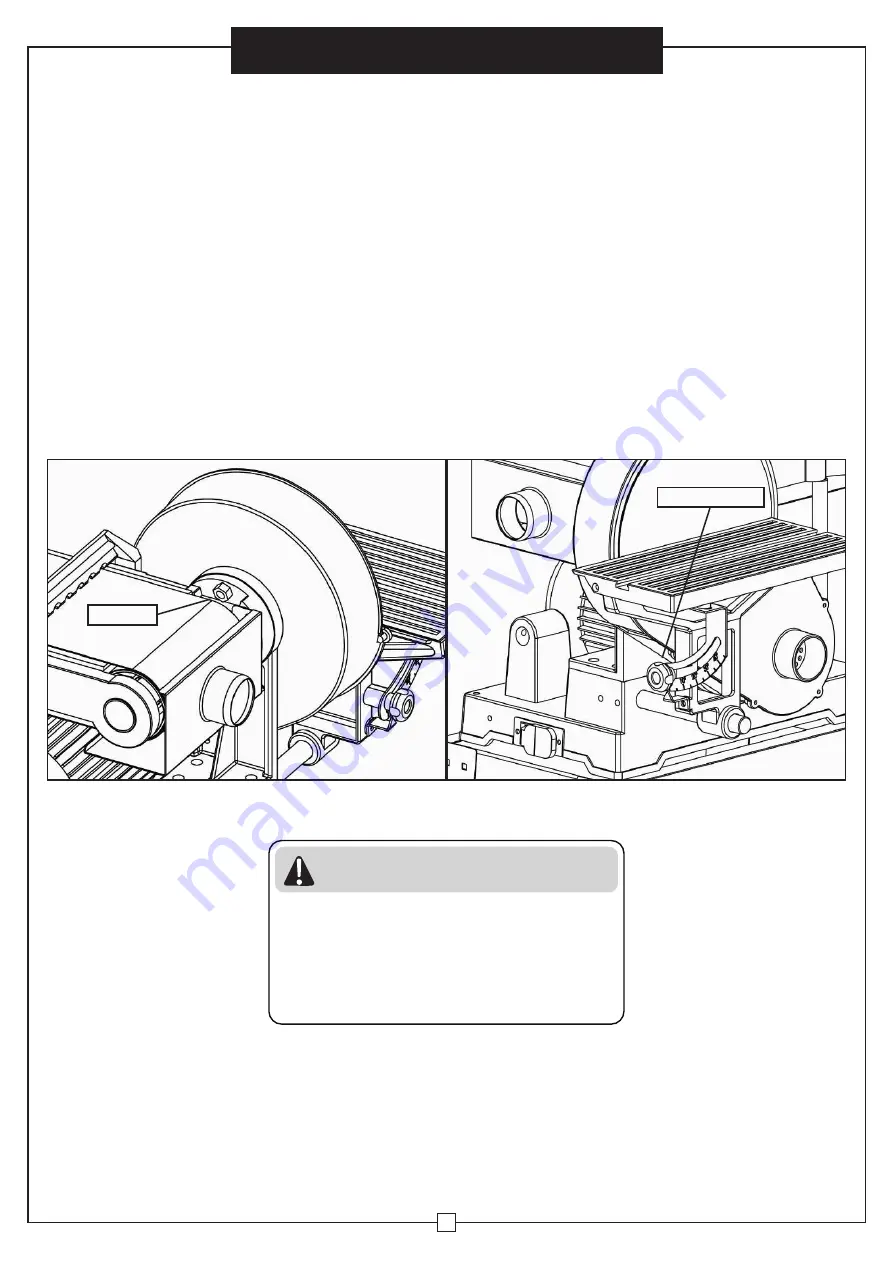

1. There is a hex nut holding the belt in position. To adjust the belt sander angle, loosten the nut,

then tilt belt sander to horizontal position, vertical position, or any in between. Tighten nut once

desired angle is achieved.

2. Stops are provided for horizontal and vertical positions.

Adjusting Table Angle:

Adjusting Table Angle:

3. Loosten the table locking knob, then tilt table to desired angle and tighten the locking knob.

Indices on table assembly will show table angle.

4. Loosten the set screw on the support bar to adjust table position. Move the table to within 1/16"

of the abrasive, then tighten the set screw.

Using The Miter Gauge:

Using The Miter Gauge:

5. Use miter gauge to maintain a precise angle when sanding, and also to secure the workpiece for

a more even finish.

Hex Nut

Locking Knob

MAINTENANCE

MAINTENANCE

WARNING

Before performing any inspection,

cleaning, or maintenance procedures,

make sure the machine's power switch

is in the "OFF" position and that the

power cord is unplugged.

1. Check for loose hardware, misaligned or binding belts, or any other conditions that may impede operation

of the sander before each use.

2. The machine vibrates during normal operation, however if abnormal noise or vibration occurs, cease use

of the sander and do not continue operation until the problem has been corrected.

3. Apply paste wax to the table to make feeding and pivoting the workpiece easier.

4. Use compressed air to clear work surfaces and moving parts of dust and debris produced by sanding.

5. Change abrasive surfaces whenever they are glazed or damaged.