Operating Instructions, Parts List, Warranty, & Warranty Repair Center

IMPORTANT! Read carefully before operating this tool. Failure to operate any power tool

properly can result in personal injury and/or property damage!

Free Speed (RPM) ………………..…..15,000

Air pressure (PSI) ……………..…………..90

Hose Size (ID) …………………...……..… 3/8”

Air Inlet (NPT) ………………………..…... 1/4”

Disc Size …………………………………………..2”

Avg. Air Consump.(cfm).………………… 3

Overall Length ……….………................ 3.7”

Weight (Lbs) …….…….. …..………...…... 1.5

Safety

1.

Always use impact type sockets that are designed for impact wrenches.

2.

Always wear approved eye protection.

3.

Have throttle in “off” position when connecting to air supply.

4.

Disconnect tool before performing service, changing accessories, or when not in use.

5.

Always be in a safe working distance from others when using tools.

6.

Keep tools clean and oiled for best and safest performance.

7.

Follow instructions for lubricating and changing accessories.

8.

Do not wear loose fitting clothing and remove watches and rings.

9.

Use proper hose and fitting. Never use quick change couplings attached at tool.

10.

Keep proper footing and balance at all times.

11.

Never carry too by the hose. Keep hoses from heat, oil, and sharp edges. Check hoses

for weak or worn condition before each use, making certain that all connections are

secure.

Lubrication

Lubricate the tool daily with a good grade of air tool oil. The oil can be applied directly into

the air inlet of the tool and then run the tool. A rust inhibitor oil is acceptable for air tools.

Air Supply

Tools of this class operate on a wide range of air pressure. It is recommended that air

pressure of these tools measure 90 PSI at the tool while running free. Higher pressure and

unclean air will shorten the tool’s life and may create a hazardous condition.

Water in the airline will cause damage to the tool. Ensure that the air tank is drained daily

Clean the air inlet filter screen on at least a weekly basis. The recommended hookup

procedure can be viewed in the illustration below.

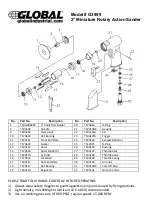

Model # G3999

2” Miniature Rotary Action Sander