3

55

1

2

2

4

5

55

22

2

R-450A

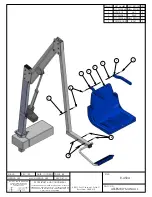

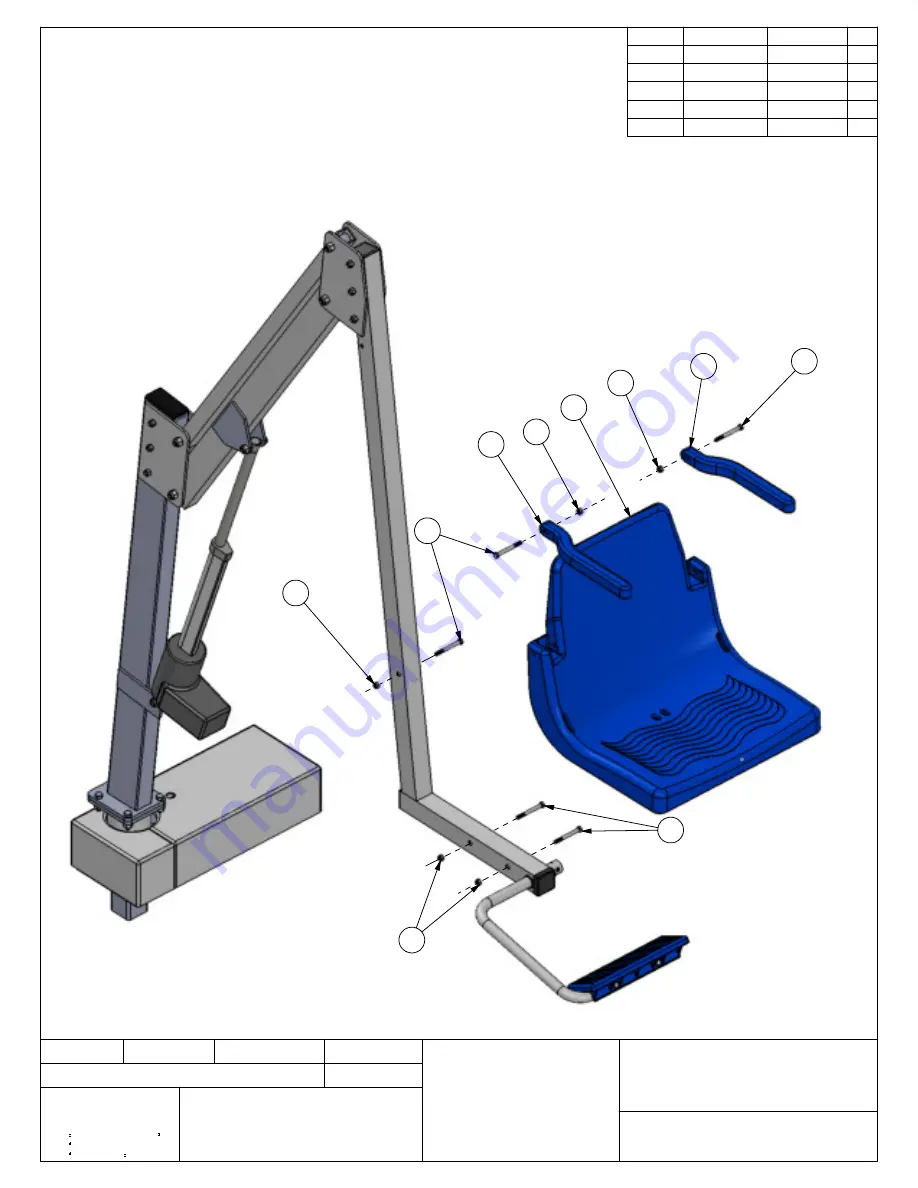

ITEM NO. PART NUMBER DESCRIPTION QTY.

1

GLCSEATB-6R ARM REST RH 1

2

NUT313-18

NUT

5

3

GLCSEATB-1

SEAT

1

4

GLCSEATB-6L ARM REST LH 1

5

BOLT313-18-3

BOLT

5

ASSEMBLY MANUAL

PROPRIETARY AND CONFIDENTIAL

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE

PROPERTY OF Global Lift Corporation. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE WRITTEN PERMISSION OF

Global Lift Corp. IS PROHIBITED.

DO NOT SCALE DRAWING

DWG. NO.

SCALE:

ANGLES 1 DEGREE

HOLES .000 THRU .015

FILLET RADII .000 THRU + .094

FRACTIONAL DIMESIONS .125

.031

.062

.125

XXX. =

XX. =

X. =

UNLESS OTHERWISE SPECIFIED

DIMENSIONS ARE IN INCHES

TOLERANCES ARE:

REV: 100

DWR: B.E.

APVD BY: J.I.

DATE: 11/12/2013

TITLE:

WEIGHT: LBS

MACH WEIGHT: LBS

684 N. Port Crescent, Suite C

Bad Axe, MI 48413