3

An Important Message for Installers and Operators

These instructions include information intended to assure correct installation, operation and trouble-free

service. Prior to attempting installation, service or operation, be certain of the following:

1. You have fully read and understood these instructions

2. You have the tools required and sufficient training to use them.

3.You have met all code, installation and application restrictions.

4. You are familiar with the function and operation of the unit.

5.That these instructions are followed exactly as given.

Inspect for Damage

This unit was packaged and inspected at the factory and

was in excellent condition at the time of shipment. The

transit company or others involved in it’s handling are

responsible for loss or damage that may have occurred

after the unit left the factory. Inspect the underside of the

cabinet and packaging for damage such as a forklift

might cause. Also, look for bent components that might

indicate that the unit has been dropped. Open any

cartons that appear to have damage and inspect the

contents. Always attempt to inspect the unit prior to the

departure of the delivery driver so that the driver can

detail the damage on the freight bill. If damage is found

after uncrating, immediately call the delivery carrier and

request an inspection. Most carriers require that

inspections be done within 15 days of delivery. Retain all

packaging and crating materials for damaged units until

the inspection is complete.

Locating the Cabinet

Select a location where the cabinet will not be exposed

to heat sources such as sun through windows, heating

vents, etc. Extension cords should be avoided, so a

receptacle of the proper type and current rating should

be within 6 feet of the unit’s location.

CLEARANCE REQUIREMENTS: Allow a minimum of

twelve (12) inches between the top of the cabinet

and ceiling and a minimum of two (2) inches

between the back of the cabinet and wall for proper

air circulation through the condensing unit.

Installing the Cabinet

(Models with Top Mounted Compressors)

Whenever possible, leave the crate skid on the cabinet

until it is moved close to the final position. If the cabinet

must me moved through a narrow doorway, it may be

necessary to remove the crate skid. Wood runners are

provided on the underside of the cabinet for ease in

sliding.

The runners should be left attached to the

cabinet when the skid is removed and should remain

attached until after the legs are installed

.

The cabinet can then be pushed around more easily

without scratching the floor. The runners also prevent

damage to the electrical receptacle and condensate pan

hardware on the cabinet bottom. After the cabinet has

been moved to the approximate final location, remove

the package containing the legs from the cabinet interior.

Tape the doors to prevent accidental opening while

handling. Raise the sides of the cabinet high enough to

mount the legs at the locations provided on the bottom of

the cabinet. Level the cabinet by means of the leg

adjustments. The cabinet doors are self-closing, and the

cabinet must be level to operate properly.

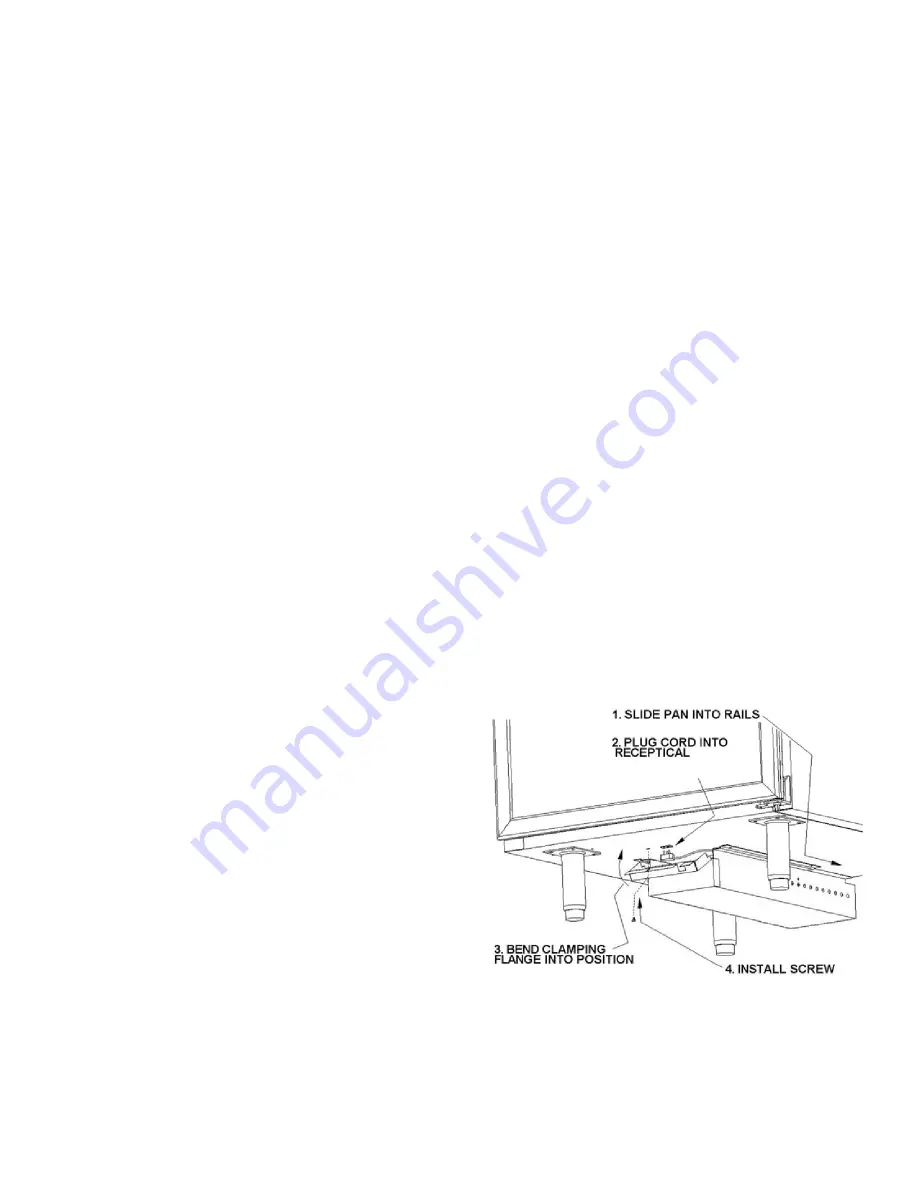

Condensation Pan

(Models with Top Mounted Compressors)

The condensate pan assembly mounts in the “track” pro-

vided on the underside of the cabinet. The pan assembly

must be pushed in from the front of the cabinet far

enough to be positioned under the condensate drain

tube on the backside of the cabinet.

NOTE: THERE IS A PROTECTIVE COVER OVER THE

ELECTRICAL RECEPTACLE ON THE CABINET BOT-

TOM WHICH MUST BE REMOVED AND DISCARDED

PRIOR TO THE CONDENSATE PAN INSTALLATION.

The pan assembly must be secured by a #10-32 thumb

screw and is designed to prevent accidental unplugging

of the pan supply cord. The pan must be in the correct

position to insert the thumb screw. Shut off the power

supply before plugging in pan supply cord.

Installing the Cabinet

(Models with Bottom Mounted Compressors)

To remove the skid the skid mounting clips, located

behind the front griII must be removed.