4

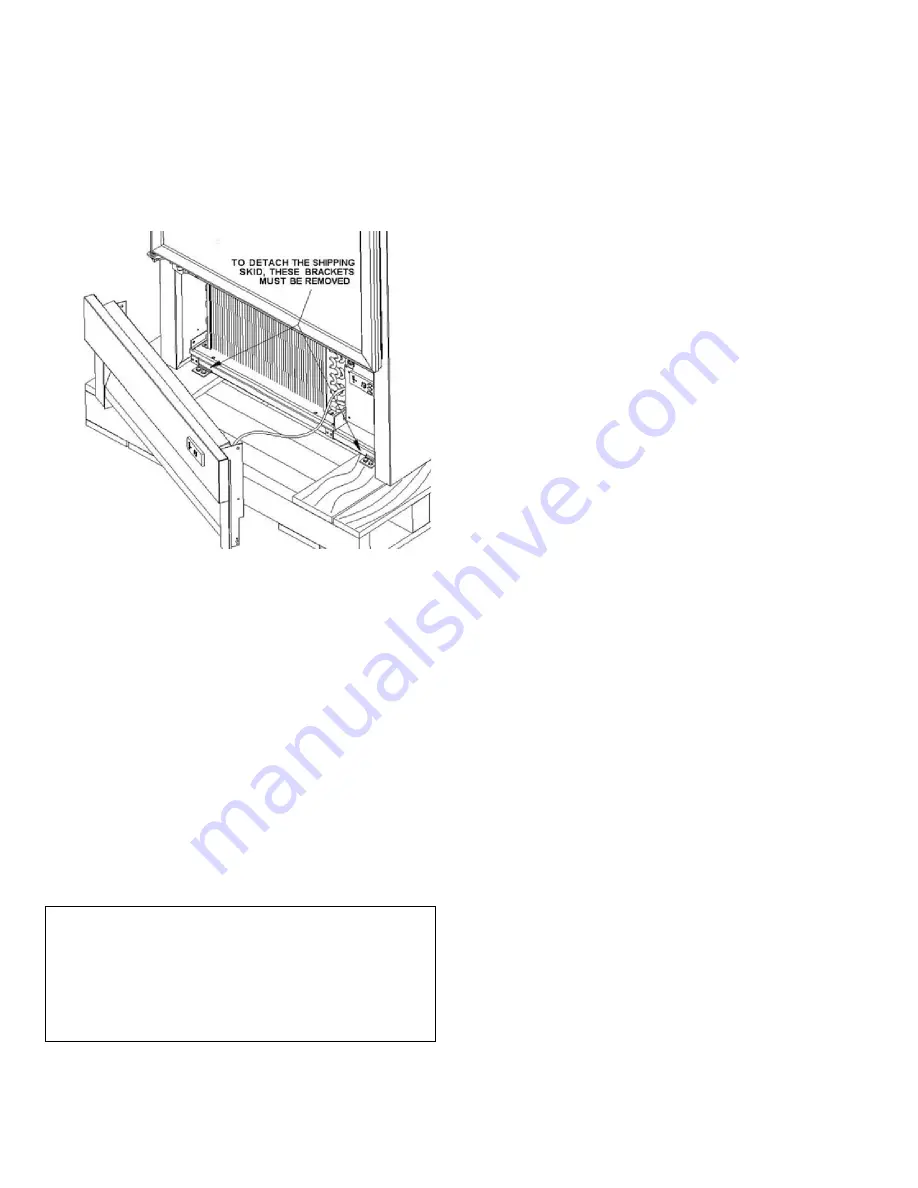

CAUTION: There is cable connecting the grill

mounted display to the control box. Take care to

avoid pulling on it.

Once the front clips are removed the cabinet can be slid

forward to clear the rear mounting clips. After removing

the skid, move the cabinet into location. Make sure the

cabinet is level so that the self-closing doors operate

properly.

Electrical Requirements

Check the electrical rating plate on the cabinet to be

sure the one required matches your requirements.

Check voltage and amp draw on the serial plate to

determine proper fuse and wire size.

CAUTION:

All cabinets must have a grounded

supply receptacle. The cord provided must be used

only with its ground pin intact.

It is recommended that a separate supply circuit be run

for each cabinet to prevent the possibility of another

appliance blowing a fuse, causing subsequent loss of

product. Caution: The insulated space of this cabinet is

sealed to maintain peak efficiency. Holes drilled in the

cabinet may destroy that seal and damage electrical

wiring located in the insulated space.

CAUTION

:

The insulated space of this cabinet is

sealed to maintain peak efficiency. Holes drilled in the

cabinet may destroy that seal or damage electrical

wiring located in the insulated space.

DAMAGED ELECTRICAL WIRING OR WET

INSULATION CAUSED BY DRILLING WILL VOID

THE WARRANTY.

N.S.F. Required Installation Procedures

Shelf Brackets:

To comply with NSF requirements, the shelves and

their brackets must be removable without the use of a

tool. At the time of initial installation, all shelf bracket

screws should be loosened with a tool and re-tightened

“hand tight”.

Floor sealing of cabinets without legs or casters:

(bottom mount cabinets only)

1) Remove front grill.

2) Seal around entire outside perimeter of cabinet

(except sides, if against wall) with an N.S.F.

approved sealant (GE-802, DOW-732).

3) Sealed joint should be smooth and easily cleanable.

4) Replace front grill.

Cabinet Start-up

Once the cabinet has been located in its permanent

location and the proper power and grounding has been

provided, the following items must be checked or

completed:

a.)

Cut and remove the compressor shipping strap

(where supplied) so the compressor “floats” freely.

b.)

Check for traces of oil on the compressor pan which

could mean a broken or leaking refrigeration line.-

UNDER NO CIRCUMSTANCE SHOULD THE

COMPRESSOR BE STARTED WHEN OIL IS

PRESENT UNTIL AFTER AN INSPECTION BY A

SERVICE TECHNICIAN.

c.)

INSPECT FACTORY WIRING FOR TERMINALS

THAT MIGHT HAVE LOOSENED DURING

SHIPPING TIGHTEN ALL SCREW TYPE

TERMINALS

d.)

Check the refrigeration lines to see that they are

'free" and no damage was done during shipping.

e.)

Check that the fan blade(s) rotate freely.

f.)

Turn on the main power switch. Once the compres-

sor starts, the voltage should be checked at the

compressor terminals to determine if there is

proper voltage to the compressor. The voltage

should not exceed the 10% above or below the

rated compressor voltage.

EXAMPLE: If the supply

voltage reads 115 volts with the unit off and it

drops below 103 volts once the compressor is

running, it may indicate that the supply wiring is

insufficient

.