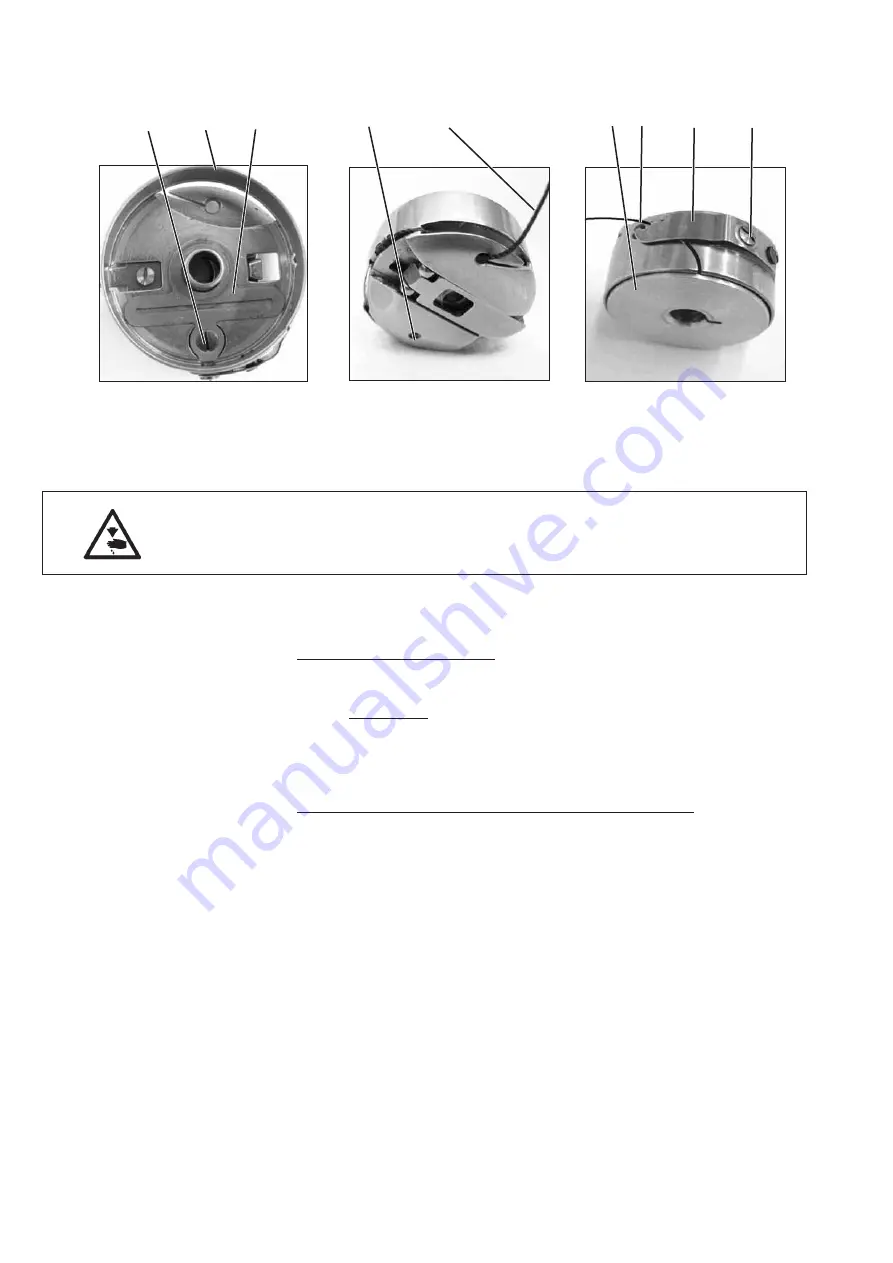

7.4.2

Hook thread tension adjustment

Attention! Danger of injury!

Do adjustments when the main switch is switched off and motor

stopped!

–

The hook thread tension depends on the adjustment of springs (1)

and (2).

Tension spring (1) adjustment

–

Remove the bobbin case (3) from the machine and insert a

full-wound bobbin (4).

–

Do a complete threading according to picture (B).

–

Regulate the spring (1) pressure with a screw (5) so that the thread

tension is in balance with the case and bobbin weight - when hung

down on the thread end (6), the case is dropping slowly with its

own weight.

Adjustment of bobbin brake spring at the thread trimming (2)

–

Bobbin braking should be as small as possible because it causes

difference of tensions of full and empty bobbin and subsequently

of thread interlacing in the stitch (defective look of the seam).

–

Regulate the bobbin braking with a screw (7) and watch the bobbin

unwinding after the thread trimming: remove the case (3) from the

machine, grip it so that the bobbin cannot turn and pull out the

thread end (8). At a correct adjustment, approx. 10 mm of thread

will be pulled out of the case.

16

A

B

C

7

3

2

7

8

4

6

1

5

www.ae-sewingmachines.co.uk