INSTRUCTION MANUAL

Issue.

08 / 2004

Pag.

29 - 42

WARNING

7.2

ELECTRICAL SETUP CHECKS.

The operations for the first start are very important in order to assure a correct and lasting

functioning of the L.B.

Therefore, we recommend you to carry out the operations described below with the utmost care.

Check that the network voltage is the same as the one reported on the plate.

Check that the current is supplied with protection disposal (not included in the L.B. )

Check the good condition of the feeder and the presence of the earthed neutral

(yellow/green). Connect and place the earthed neutral with the utmost care

and according to the current regulations.

Insert the plug

À

in the outlet placed on the power unit console, see

Picture 7-

15

Î

Supply voltage to the L.B. by operating on the

main switch

sulla on the

console of the power unit, see

Picture 7-16

Î

Photo 7-17

Use the remote control .

Check that the

button

À

for

EMERGENCY is

disabled. Now,

press button

Á

UP

only for few

seconds and check

that the lift is

moving.

If the lift does not move, do not insist because the wrong wiring rotation of the

engine, and therefore also of the hydraulic pump, may cause damage to the

hydraulic plant.

In this case invert the two phases of the feeder. DO NOT

À

EMERGENCY

Á

UP

Â

DOWN

Ã

SAFETY RELEASE

make any intervention on the terminal board of

the electric engine.

Test its correct functioning by carrying out a complete up and down stroke.

Make a final check "at sight" at all the pipes connections, at the junctions and at the cylinder in order to

find out eventual leaks of oil. In this case lock tight the junction in the leaks locations.

Not observing the above mentioned instructions cause the invalidation of the warranty conditions,

and any damage that may follow will not be imputed to the Manufacturer.

Summary of Contents for Super Rotax

Page 2: ...USERS MANUAL Year of Manufacture ...

Page 21: ...INSTRUCTION MANUAL Issue 08 2004 Pag 19 42 7 1 1 ELECTRICAL PLANT DIAGRAM ...

Page 22: ...INSTRUCTION MANUAL Issue 08 2004 Pag 20 42 7 1 2 HYDRAULIC PLANT DIAGRAM ...

Page 23: ...INSTRUCTION MANUAL Issue 08 2004 Pag 21 42 7 1 3 PNEUMATIC PLANT DIAGRAM ...

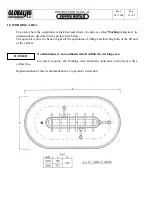

Page 42: ...INSTRUCTION MANUAL Issue 08 2004 Pag 40 42 14 OVERALL DIMENSIONS DRAWING ...