INSTRUCTION MANUAL

Issue.

08 / 2004

Pag.

37 - 42

11.

START AND STOP – SAFETY PROCEDURES.

11.1.

Start up operations

Starting position: the bench is completly lowered and it may be in one of the possible situations

that follows.

-

With crossbeams and bases

-

With side runners

-

With the Globaljig system and the vehicle already in position

-

With side runners and vehicle

Before activating the lifting bench:

-

Check if the power is available.

-

Check the Working Area, make sure that the area is free from objects or people.

-

Check the correct position of the ramps.

-

Check the load stability.

11.2.

Stopping operations

At the end of the job or when you have to have a long break, you should:

–

Reposition the bench horizontally and at its minimum height .

–

Turn off the main switch (on the power unit console) in position

O.

11.3.

Stopping operations in case of a blackout.

In case of a blackout, the lifting bench is out of work and even if it is still safe, (the barring gear is

activated), you must turn off the main switch on the console, until the power is restored.

Summary of Contents for Super Rotax

Page 2: ...USERS MANUAL Year of Manufacture ...

Page 21: ...INSTRUCTION MANUAL Issue 08 2004 Pag 19 42 7 1 1 ELECTRICAL PLANT DIAGRAM ...

Page 22: ...INSTRUCTION MANUAL Issue 08 2004 Pag 20 42 7 1 2 HYDRAULIC PLANT DIAGRAM ...

Page 23: ...INSTRUCTION MANUAL Issue 08 2004 Pag 21 42 7 1 3 PNEUMATIC PLANT DIAGRAM ...

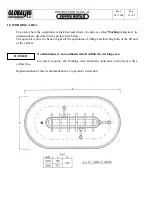

Page 42: ...INSTRUCTION MANUAL Issue 08 2004 Pag 40 42 14 OVERALL DIMENSIONS DRAWING ...