INSTRUCTION MANUAL

Issue.

08 / 2004

Pag.

39 - 42

WARNING

13.

REPAIR/ COMPONENTS AND SPARE PARTS

13.1.

REPAIR

PROBLEM POSSIBLE

CAUSE SOLUTION

The lifting bench does not go

up or down

–

Power current fuse (F1) or

transformer fuses (F2/F3)

damaged.

–

Limit switch for the up-

stroke damaged or with no

connection.

–

Damage t the electric or

hydraulic plant.

–

Replacement of the

damaged fuses.

–

Restore the connection or

replace the limit switch.

–

Call the technician.

13.2.

COMPONENTS AND SPARE PARTS

The documentation of this chapter concerns the diagrams and the drawings described in the

following chapters:

–

Electrical Diagram

cap.7

–

Hydraulic Diagram

cap.7

–

Pneumatic Diagram

cap.7

–

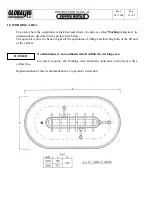

Overall dimensions drawing

cap.14

We advise the operator that it is not possible to provide drawings or information about all the

component parts of this manual. The manufacturer will:

–

Undertake a more detailed test at his own premises or at Assistance Network’s workshop.

–

Be at Customer’s disposal in order to reply to any questions concerning all the components, in

order to grant the correct functioning of the equipment.

The electrical and hydraulic components will be replaced only after manufacturer’s check in order

to determine the cause of the damage.

In case of replacement or assistance, the customer should contact the authorised

local distributor.

The manufacturer is not responsible for injury to people or damage happened during repair carried out

outside manufacturer’s premises or by non authorised staff.

Summary of Contents for Super Rotax

Page 2: ...USERS MANUAL Year of Manufacture ...

Page 21: ...INSTRUCTION MANUAL Issue 08 2004 Pag 19 42 7 1 1 ELECTRICAL PLANT DIAGRAM ...

Page 22: ...INSTRUCTION MANUAL Issue 08 2004 Pag 20 42 7 1 2 HYDRAULIC PLANT DIAGRAM ...

Page 23: ...INSTRUCTION MANUAL Issue 08 2004 Pag 21 42 7 1 3 PNEUMATIC PLANT DIAGRAM ...

Page 42: ...INSTRUCTION MANUAL Issue 08 2004 Pag 40 42 14 OVERALL DIMENSIONS DRAWING ...