206M 201805

35

whether LEDs or indicator light are damaged. Checking ends and display shows Fig 11-1.

Enter position sensor signal check. Press [SET] key to exit.

12.2 Position sensor signal check

This function can check whether position sensor, main shaft, main board circuit are with

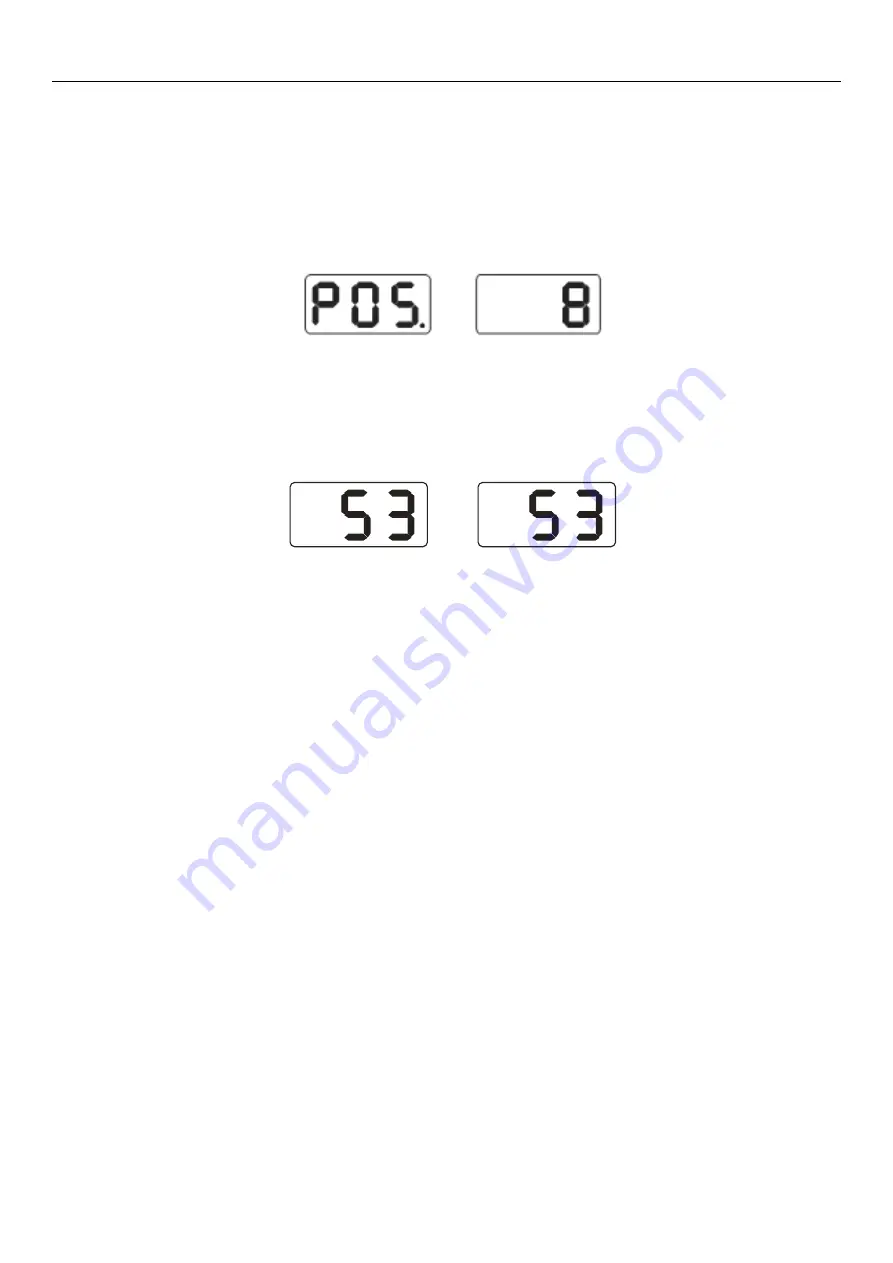

error. As per Fig 12-1, slowly rotate main shaft, value shown in right side display changes

accordingly. Rotate clockwise, value increases; Rotate anticlockwise, value decreases.

Normally, value changes among 0-63. Press [a+] key to enter press sensor signal check.

Press [SET] key to exit.

Fig 12-1

12.3 Press sensor signal check

This function can check whether press sensor , main board signal circuit and power board

are with error.

Follow 12.2 and press [a+] key to enter (Fig12-2). Then lightly press main shaft, if normally,

values shown on display should be changed. Press [a+] or [SET] key to exit.

Fig 12-2

13. Trouble shooting

13.1 Manually rotate wheel to rating speed, LEDs are not off and balancing test is going on.

Computer board, position sensor and cables should be checked.

13.2 After machine power on, there is no display. Check power switch indicator light. If light is

off, power supply gets problem. Otherwise, check power board, computer board and

cables.

13.3 Inaccuracy of precision normally is not caused by balancer. It may be caused by wrong

wheel installation, inaccurate counterweight or inaccurate 100g weight. The original

100g weight must be kept properly for self-calibration only

13.4 Unstable data and poor repeatability of data normally are not caused by balancer. It may

be caused by wrong wheel installation or unstable installation of machine. Machine

should be well fixed on ground by bolt.