0020313973_01 Compact Installation and maintenance instructions

49

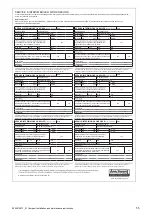

Code/meaning

Possible cause

Measure

F.29

Ignition and check faults during

operation

–

flame has gone out

Reference pressure pipe not

connected

1.

Check whether the reference pressure pipe is connected

between the gas valve assembly and the restrictor for the

reference pressure pipe.

2.

Check whether the reference pressure pipe is connected

between the restrictor for the reference pressure pipe and

the distribution pipe.

F.32

Fan fault

Plug on fan not plugged in or is

loose

▶

Check the plug on the fan and the plug connection.

Multiple plug loose/not plugged

in

▶

Check the multiple plug and plug connection.

Interruption in the cable harness

▶

Check the cable harness.

Fan blocked

▶

Check that the fan works correctly.

Hall sensor defective

▶

Replace the Hall sensor.

Electronics defective

▶

Check the PCB.

F.33

Excessive pressure losses from

the air/flue system

Air/flue pipe blocked or partially

blocked

▶

Check the entire air/flue pipe.

Fan defective

▶

Check that the fan works correctly.

PCB defective

▶

Replace the PCB.

Temperature sensors defective

or not connected correctly

▶

Ensure that the electrical connection for the temperature

sensors has been established correctly, that they are not

corroded, and that they click into place correctly on the

connecting piece.

CO

₂

content too low

▶

Check the CO2 setting and, if required, increase the CO

₂

content while taking the tolerances into consideration.

(

▽

If the increase in the CO

₂

content is not sufficient, set dia-

gnostics code

d.85

to 10.

Presence of a shunt pump in

the circuit

▶

This product is not compatible with a shunt pump in the install-

ation; remove the shunt pump and change the installation's ba-

sic diagram accordingly.

Excessive counter-pressure in

the air/flue pipe

▶

If required, protect the product (wind deflector).

F.46

Cold water sensor short circuit

Cold water sensor defective

▶

Replace the cold water sensor.

Short circuit in the cable har-

ness

▶

Check the cable harness.

F.49

Fault: eBUS

Short circuit in the eBUS con-

nection

▶

Check that the eBUS connection works correctly.

eBUS overload

▶

Check that the eBUS connection works correctly.

Different polarities at the eBUS

connection

▶

Check that the eBUS connection works correctly.

F.61

Fault: Fuel control valve

Short circuit in the cable har-

ness for the gas valve assembly

▶

Check the cable harness for the gas valve assembly.

Gas valve defective

▶

Replace the gas valve.

PCB defective

▶

Replace the PCB.

F.62

Fault: Delayed shutdown of the

fuel control valve

Gas valve defective

▶

Replace the gas valve.

PCB defective

▶

Replace the PCB.

Ignition electrode defective

▶

Replace the ignition electrode.

F.63

Fault: EEPROM

PCB defective

▶

Replace the PCB.

F.64

Fault: Electronics/temperature

sensor

Flow temperature sensor short

circuit

▶

Check that the flow temperature sensor works correctly.

Return temperature sensor

short circuit

▶

Check that the return temperature sensor works correctly.

PCB defective

▶

Replace the PCB.

F.65

Electronics temperature fault

Electronics overheated

▶

Check the external heat effects on the electronics.

PCB defective

▶

Replace the PCB.

F.67

Fault: Electronics/flame

Implausible flame signal

▶

Check the flame signal.

PCB defective

▶

Replace the PCB.

Fault in the flue gas route

▶

Check the entire flue gas route.

Summary of Contents for Compact 24c-AS/1

Page 59: ......