30

Installation and maintenance instructions Compact 0020313973_01

9.6.3

Checking the gas flow rate

The boiler is fitted with a multifunctional automatic gas valve

which ensures that the precise air/gas ratio is provided un-

der all operating conditions. The gas flow rate has been set

during production and does not require adjustment. With the

front casing fitted check the gas flow rate of the boiler as fol-

lows:

▶

Start up the product with the check programme

P.01

.

▶

In addition, ensure that maximum heat can be dissipated

into the heating system by turning up the room thermo-

stat.

▶

Wait at least 5 minutes until the boiler has reached its

operating temperature.

▶

Ensure that all other gas appliances in the property are

turned off.

▶

Measure the gas flow rate at the gas meter.

▶

Compare the measured values with the corresponding

values in the table.

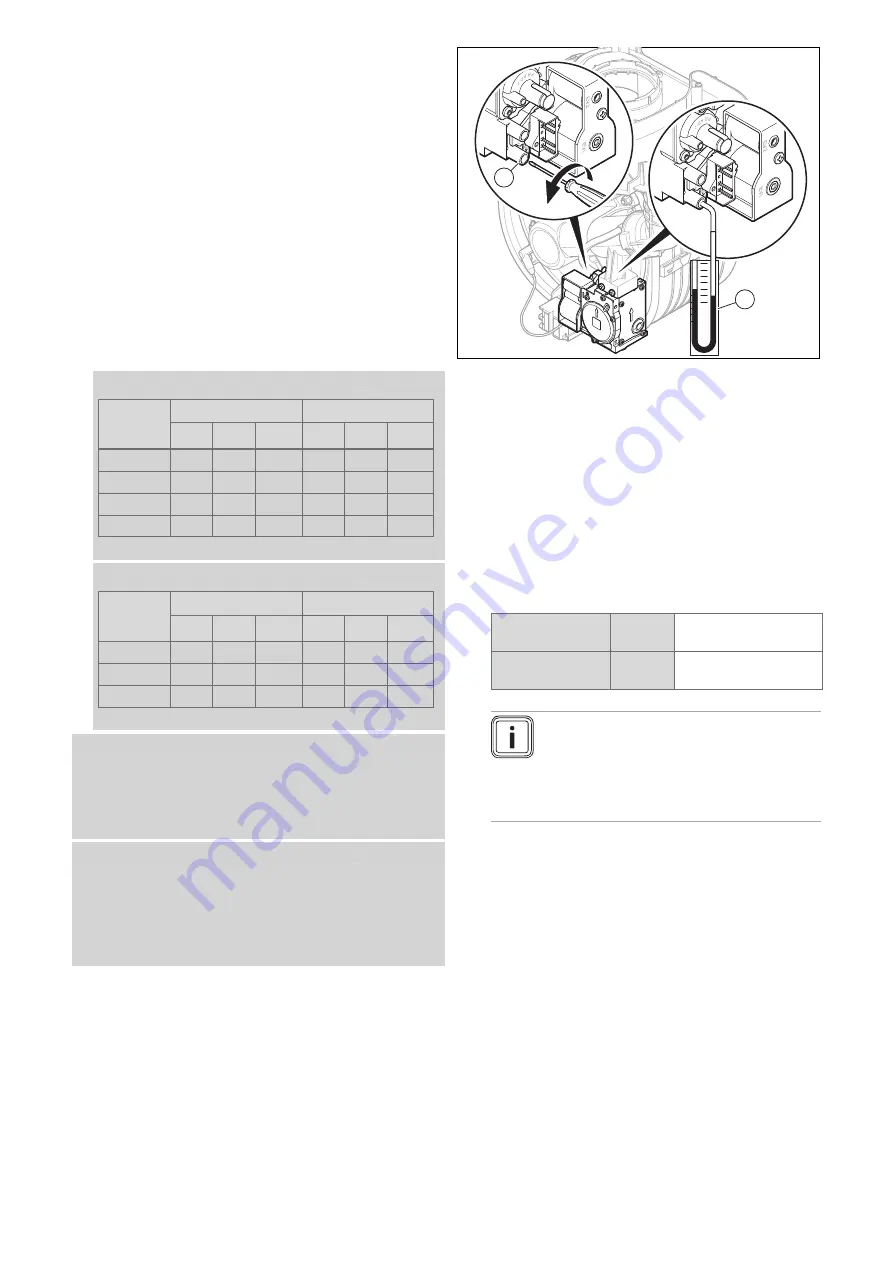

Validity:

Compact 24c-AS/1 (H-GB) OR Compact 24c-AS/1 (P-GB)

Qnw from

the data

plate

H gas in m

³

/h

P gas in m

³

/h

Nom.

+5%

−

10%

Nom.

+5%

−

10%

6.2

0.65

0.68

0.59

–

–

–

8.4

–

–

–

0.34

0.36

0.31

18.8

1.98

2.08

1.78

0.77

0.81

0.69

24

2.53

2.66

2.28

0.98

1.03

0.88

Validity:

Compact 28c-AS/1 (H-GB) OR Compact 28c-AS/1 (P-GB)

Qnw from

the data

plate

H gas in m

³

/h

P gas in m

³

/h

Nom.

+5%

−

10%

Nom.

+5%

−

10%

7.2

0.76

0.80

0.68

0.29

0.30

0.26

24.5

2.58

2.71

2.32

1.00

1.05

0.90

28

2.95

3.10

2.66

1.15

1.21

1.04

Condition

: Gas flow rate not in the permissible range

▶

Check all of the piping and ensure that the gas flow rates

are correct.

▶

Only put the product into operation once the gas flow

rates have been corrected.

Condition

: Gas flow rate in the permissible range

▶

End check programme

P.01

.

▶

Allow the boiler to cool down by allowing pump overrun to

operate for a minimum of two minutes.

▶

Record the boiler maximum gas flow rate onto the

Benchmark gas boiler commissioning checklist.

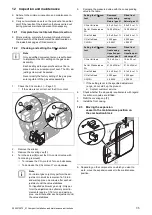

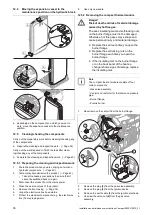

9.6.4

Checking the gas connection pressure/gas

flow pressure

1.

Temporarily decommission the product. (

2.

Hinge the electronics box downwards.

2

1

3.

Turn the screw on the gas pressure measuring point

(1)

anti-clockwise.

–

Anti-clockwise (

↺

): Two rotations

4.

Connect a manometer

(2)

to the test nipple

(1)

.

–

Working materials: U tube manometer

–

Working materials: Digital pressure gauge

5.

Hinge the electronics box upwards.

6.

Open the gas stopcock.

7.

Start up the product with check programme

P.01

(in

doing so, set the output to the maximum). (

8.

Measure the gas connection pressure/gas flow pres-

sure against the atmospheric pressure.

Permissible connection pressure

Great

Bri-

tain

Natural gas

H

1.7 to 2.5 kPa

(17.0 to 25.0 mbar)

Liquefied petro-

leum gas

P

2.5 to 4.5 kPa

(25.0 to 45.0 mbar)

Note

The connection pressure is measured at the

gas valve assembly, meaning that the per-

missible minimum value may be 0.1 kPa (1

mbar) lower than the minimum value spe-

cified in the table.

Result 1:

Gas connection pressure/gas flow pressure in the per-

missible range

▶

Temporarily decommission the product.

(

▶

Hinge the electronics box downwards.

▶

Remove the manometer.

▶

Tighten the screw on the test nipple.

▶

Open the gas stopcock.

▶

Check the test nipple for gas tightness.

▶

Hinge the electronics box upwards.

▶

Install the front casing. (

▶

Start up the product.

Result 2:

Gas connection pressure/gas flow pressure not in the

permissible range

Summary of Contents for Compact 24c-AS/1

Page 59: ......