0020313973_01 Compact Installation and maintenance instructions

35

12 Inspection and maintenance

▶

Adhere to the minimum inspection and maintenance in-

tervals.

▶

Carry out maintenance work on the product at an earlier

point if the results of the inspection that was carried out

during previous maintenance make this necessary.

12.1

Complete Service Interval Record section

▶

After servicing, complete the relevant Service Interval

Record section of the Benchmark Checklist located on

the inside back pages of this document.

12.2

Checking and setting the CO

₂

content

Note

Only a qualified competent person is authorised

to implement the CO

₂

setting on the gas valve

assembly.

Each destroyed tamper-proof seal must be re-

placed with a new tamper-proof seal. The CO

₂

ad-

justing screw must be sealed.

Never modify the factory setting of the gas pres-

sure regulator of the gas valve assembly.

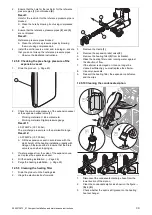

1.

Check the CO

₂

content. (

▽

If the value is not correct, set the CO

₂

content.

2

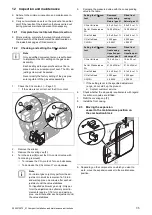

1

2.

Remove the sticker.

3.

Remove the covering cap

(1)

.

4.

Turn the screw

(2)

to set the CO

₂

content (value with

front casing removed).

◁

To increase the CO

₂

content: Turn anti-clockwise

◁

To decrease the CO

₂

content: Turn clockwise

Note

For natural gas only: Only perform the ad-

justment in small increments of a 1/8 turn

and wait approx. one minute after each ad-

justment until the value stabilises.

For liquefied petroleum gas only: Only per-

form the adjustment in extremely small in-

crements (approx. 1/16 turn), and wait ap-

prox. one minute after each adjustment until

the value stabilises.

5.

Compare the measured value with the corresponding

value in the table.

Setting the CO

₂

con-

tent

Removed

front casing

Fitted front

casing

Natural gas H

Natural gas H

CO

₂

at full load

9.0

±

0.3 vol. %

9.2

±

0.3 vol. %

Set for Wobbe index

W

₀

14.09 kW

⋅

h/m

³

14.09 kW

⋅

h/m

³

O

₂

at full load

4.9

±

0.5 vol. %

4.5

±

0.5 vol. %

CO at full load

≤

250 ppm

≤

250 ppm

CO/CO

₂

≤

0.0027

≤

0.0027

Setting the CO

₂

con-

tent

Removed

front casing

Fitted front

casing

Liquefied pet-

roleum gas P

Liquefied pet-

roleum gas P

CO

₂

at full load

10.4

±

0.3 vol.

%

10.6

±

0.3 vol.

%

Set for Wobbe index

W

₀

21.34 kW

⋅

h/m

³

21.34 kW

⋅

h/m

³

O

₂

at full load

5.4

±

0.4 vol. %

5.1

±

0.4 vol. %

CO at full load

≤

250 ppm

≤

250 ppm

CO/CO

₂

≤

0.0024

≤

0.0024

▽

If the setting is not in the specified adjustment

range, do not start up the product.

▶

Contact customer service.

6.

Check whether the air-quality requirements with regard

to carbon monoxide are fulfilled.

7.

Refit the covering cap

(1)

.

8.

Install the front casing.

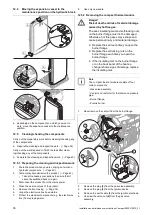

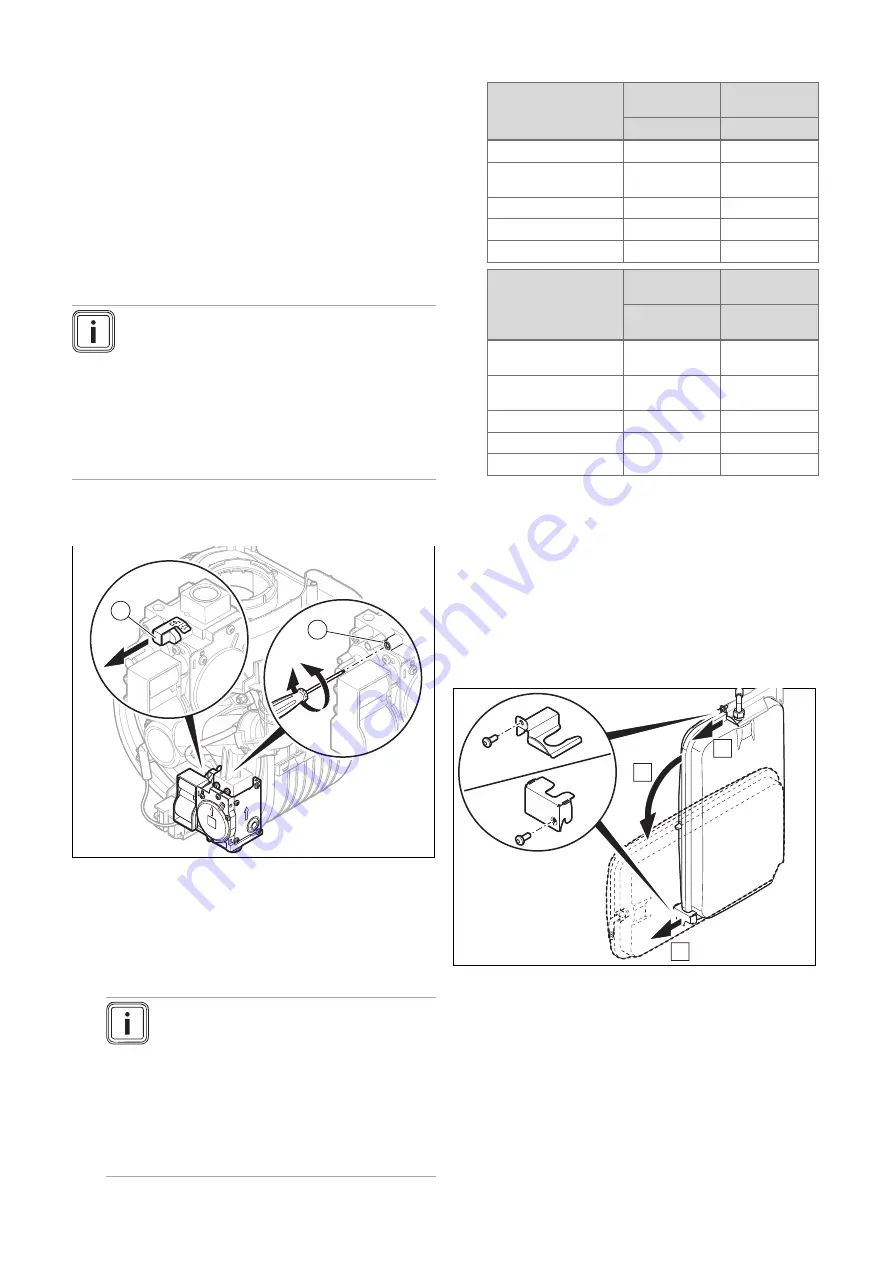

12.3

Moving the expansion

vessel to the maintenance position on

the combustion block

A

A

B

▶

Depending on the components on which you want to

work, move the expansion vessel to the maintenance

position.

Summary of Contents for Compact 24c-AS/1

Page 59: ......