0020313973_01 Compact Installation and maintenance instructions

57

H

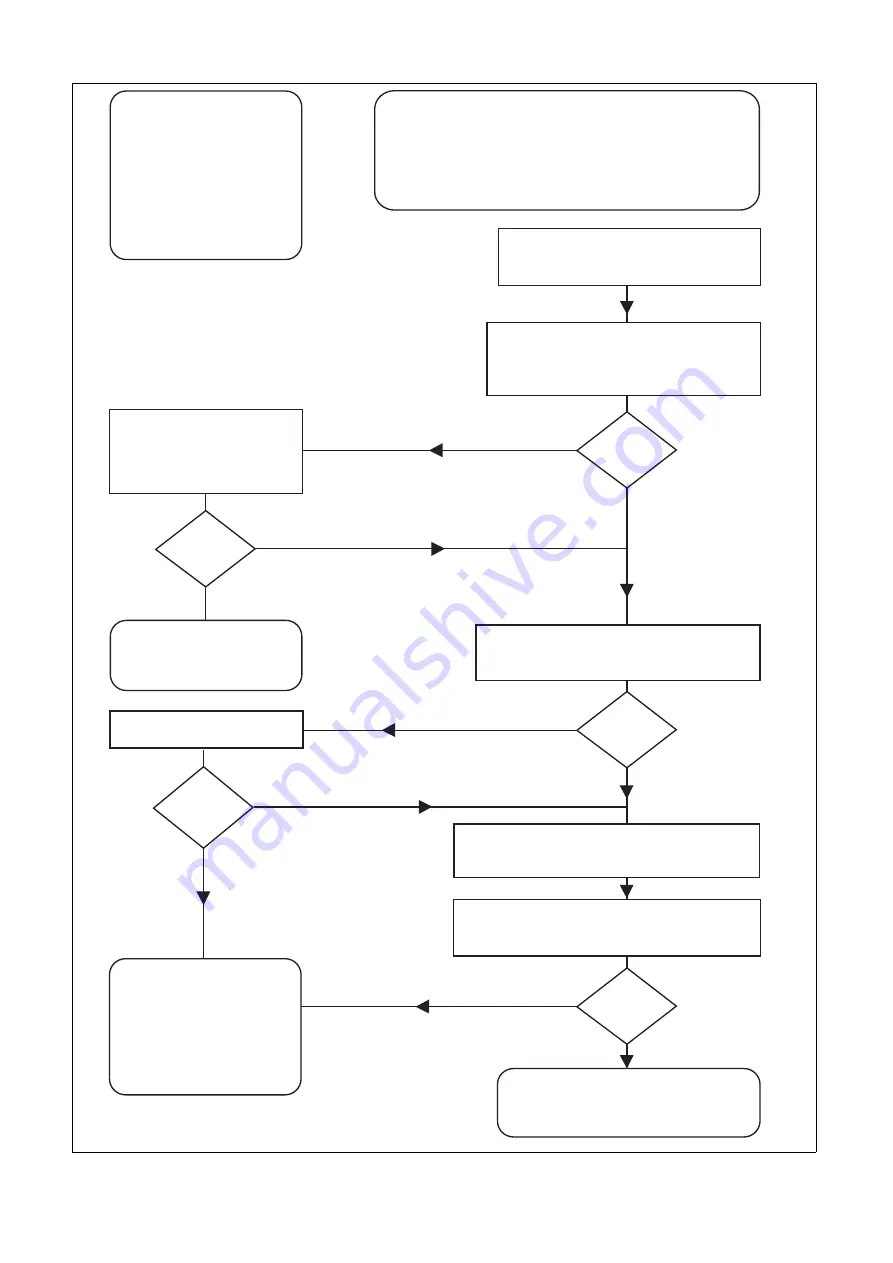

Commissioning Flow Chart

PRIOR TO CO AND COMBUSTION RATIO CHECK

The boiler manufacturer’s installation instructions should have been followed, gas type verified and gas

supply pressure/rate checked as required prior to commissioning.

As part of the installation process,

especially where a flue has been fitted by persons other than the

boiler installer

, visually check the integrity of the whole flue system to confirm that all components are

correctly assembled, fixed and supported. Check that manufacturer’s max. flue lengths have not been

exceeded and all guidance has been followed (e.g. Gas Safe Technical Bulletin TB008).

The flue gas analyser should be of the correct type, as specified by BS 7967

Prior to its use, the flue gas analyser should have been maintained and calibrated as specified by the

manufacturer. The installer must have the relevant competence for use of the analyser.

Check and zero the analyser IN FRESH AIR as per analyser manufacturer’s instructions.

NOTE

THE AIR GAS RATIO VALVE IS FACTORY

SET AND MUST NOT BE ADJUSTED

DURING COMMISSIONING UNLESS THIS

ACTION IS RECOMMENDED FOLLOWING

CONTACT WITH THE MANUFACTURER.

If any such adjustment is recommended and

further checking of the boiler is required the

installer/service engineer must be competent

to carry out this work and to use the flue gas

analyser accordingly.

If the boiler requires conversion to operate with

a different gas family (e.g. conversion from

natural gas to LPG) separate guidance will be

provided by the boiler manufacturer

CARRY OUT FLUE INTEGRITY CHECK USING ANALYSER

Insert analyser probe into air inlet test point and allow readings to stabilise.

NOTE

- where no air inlet test point is provided then a flue integrity check

with the analyser is not possible. The installer should verify that flue

integrity has been visually checked in accordance with the

“Prior to

CO and combustion ratio check”

box above before proceeding to the

“Check CO and combustion ratio at maximum rate”

stage below.

SET BOILER TO MINIMUM RATE

In accordance with boiler instructions, set boiler to operate at minimum rate (to

minimum load condition). Allow sufficient time for combustion to stabilise.

NOTE

- If manufacturer’s instructions do not specify how to set boiler to minimum

rate contact Technical Helpline for advice.

CHECK CO AND COMBUSTION RATIO AT MINIMUM RATE

With boiler still set at minimum rate, insert analyser probe into flue gas sampling

point. Allow readings to stabilise before recording.

NOTE

- If no flue gas sampling point is present and the correct procedure is not

specified in the manual, consult boiler manufacturer for guidance.

CHECK CO AND COMBUSTION RATIO AT MAX. RATE

With boiler still set at maximum rate, insert analyser probe into flue gas

sampling point. Allow readings to stabilise before recording.

NOTE

- If no flue gas sampling point is present and the correct procedure is

not specified in the manual, consult boiler manufacturer for guidance.

SET BOILER TO MAXIMUM RATE

In accordance with boiler instructions, set boiler to operate at max. rate

(full load condition). Allow sufficient time for combustion to stabilise.

NOTE - Do not insert analyser probe during this period to avoid

possible “flooding” of sensor.

Is

CO less than

350ppm and

CO/CO

2

ratio

less than 0.004

Is

O

2

20.6%

and

CO

2

< 0.2%

Is

CO less than

350ppm and

CO/CO

2

ratio

less than 0.004

BOILER IS OPERATING SATISFACTORILY

no further actions required.

Ensure test points are capped, boiler case is correctly replaced and

all other commissioning procedures are completed.

Complete Benchmark Checklist, recording CO and combustion ratio

readings as required.

TURN OFF APPLIANCE AND CALL

MANUFACTURER’S TECHNICAL HELPLINE

FOR ADVICE.

THE APPLIANCE MUST NOT BE

COMMISSIONED UNTIL PROBLEMS ARE

IDENTIFIED AND RESOLVED.

VERIFY FLUE INTEGRITY

Analyser readings indicate that combustion products

and inlet air must be mixing. Further investigation of

the flue is therefore required.

Check that flue components are assembled, fixed

and supported as per boiler/flue manufacturer’s

instructions.

Check that flue and flue terminal are not obstructed.

Is

CO

less than

335ppm

and

CO/CO

2

ratio less

than 0.004

Is

O

2

20.6%

and

CO

2

< 0.2%

Check all seals around the appliance burner,

internal flue seals, door and case seals.

Rectify where necessary.

TURN OFF APPLIANCE AND CALL

MANUFACTURER’S TECHNICAL HELPLINE

FOR ADVICE.

THE APPLIANCE MUST NOT BE

COMMISSIONED UNTIL PROBLEMS ARE

IDENTIFIED AND RESOLVED. IF

COMMISSIONING CANNOT BE FULLY

COMPLETED, THE APPLIANCE MUST BE

DISCONNECTED FROM THE GAS SUPPLY IN

ACCORDANCE WITH THE GSIUR.

NOTE:

Check and record CO and combustion ratio

at both max. and min. rate before contacting the

manufacturer.

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

Summary of Contents for Compact 24c-AS/1

Page 59: ......