10

221462C

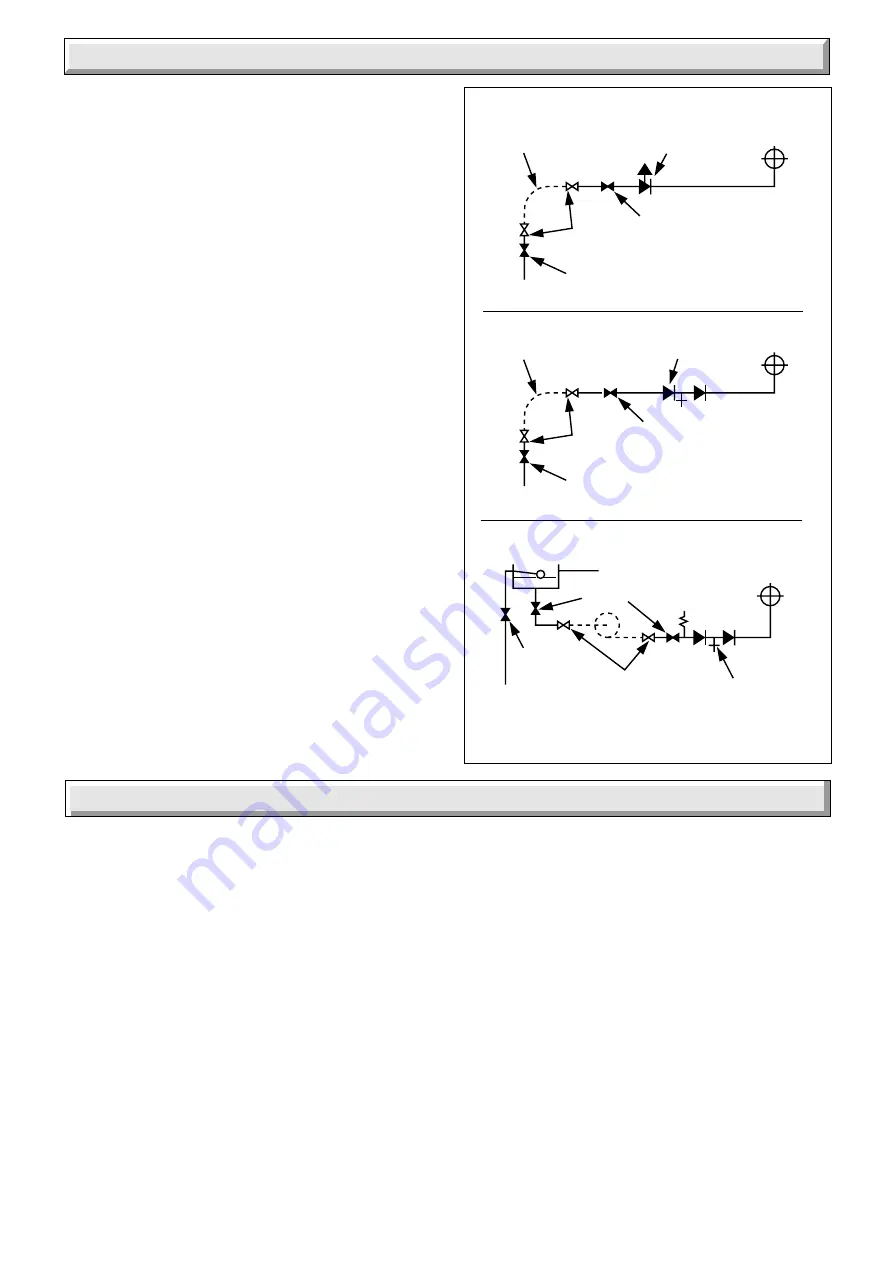

3 Water Systems

Diagram 3.5

FILLING SEALED

WATER SYSTEMS

METHOD 1

METHOD 2

METHOD 3

SUPPLY STOP

VALVE

SUPPLY

PIPE

HOSE

UNIONS

SERVICING

VALVE

TEMPORARY

HOSE

HEATING

SYSTEM

HEATING

SYSTEM

TEMPORARY

HOSE

HOSE

UNIONS

SERVICING

VALVE

SUPPLY

PIPE

SUPPLY STOP

VALVE

DOUBLE CHECK

VALVE ASSEMBLY

HEATING

SYSTEM

SERVICING

VALVE

SUPPLY

STOP VALVE

SUPPLY

PIPE

HOSE

UNIONS

DOUBLE CHECK

VALVE ASSEMBLY

OVERFLOW

CISTERN

COMBINED

CHECK VALVE

AND VACUUM

BREAKER

PRESSURE

REDUCING

VALVE

3132

3.8 Domestic Hot Water Cylinder

SINGLE FEED INDIRECT CYLINDERS ARE NOT SUITABLE.

The domestic hot water cylinder must be of the indirect coil type.

It must be suitable for working at a gauge pressure of 0.35bar

above the safety valve setting.

3.9 Water Make-up

Provision should be made for the replacing the water loss from

the system using a make up bottle mounted in a position higher

than the top point of the system, connected through a non-

return valve to the return side of either the heating circuit of the

domestic hot water cylinder.

Alternatively, provision for make up can be made by using a

filling loop.

3.10 Filling a Sealed Water System

Provision for filling the system at low level must be made. Three

methods are shown in diagram 3.5. There must be no permanent

connection to the mains water supply, even through a non-

return valve.

4.1 Appliance Preparation

Remove the controls cover by pulling it forwards and off, see

diagram 4.1.

Remove the boiler from the carton and lay it on its back.

The side grilles are packed in the bottom of the carton.

Remove the outer case by undoing the screws at the bottom

and unhooking at the top, see diagram 4.1.

Remove the two screws and attach the side grilles by hooking

over the top of the side panel and secure, see diagram 4.1.

4.2 Appliance Fitting

Refer to diagram 1.2 for fixing screw positions and minimum

clearances.

Mark position of the three fixing screws.

Drill and plug the holes, suitable for No10x2in woodscrews.

Fit the screws, leave about 6mm proud.

Hook the boiler on to the lower screw and keyhole slots at the

top, tighten all screws.

Connect the system pipework to the boiler.

Fix the flue to the flue hood in accordance with normal practice.

4 Installation