12

221462C

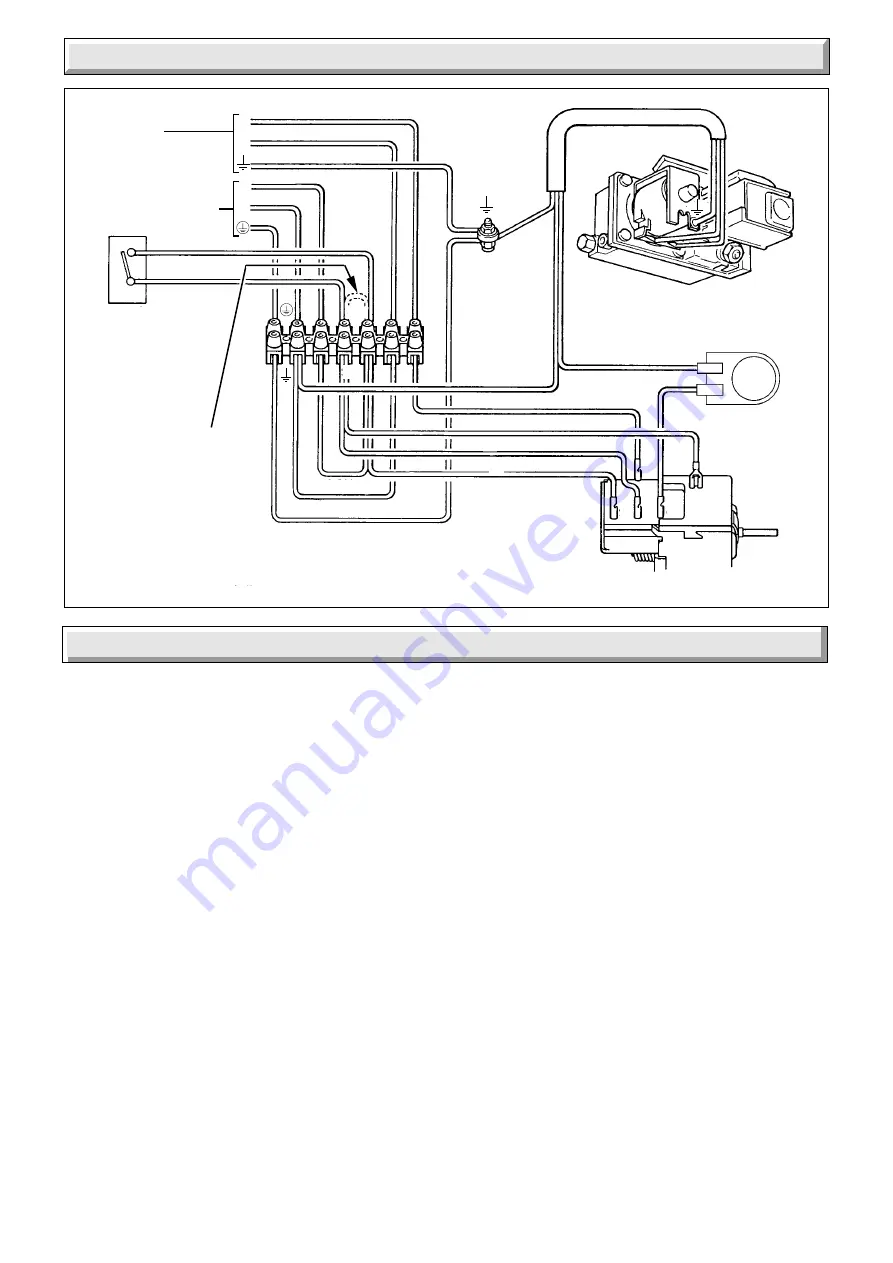

5 Electrical Wiring

6.1 All Systems

Make sure that the system has been thoroughly flushed out with

cold water without the pump in place. Refit the pump, fill the

system with water, making sure that all the air properly vented

from the system and pump.

Before operating the boiler make sure that all external controls

are calling for heat.

6.2 Sealed Water Systems Only

Flush the whole system with cold water without the pump in

place. Refit the pump and fill until the pressure gauge registers

1.5bar (21.5lbf/in

2

). Clear any airlocks and check for water

soundness.

Check the operation of the safety valve, by allowing the water

pressure to rise until the valve opens. The valve should open

/-0.3bar (+/-4.3lbf/in

2

) of the 3bar preset pressure.

Where this is not possible conduct a manual check and test.

Release cold water to initial system design pressure.

The set pointer on the pressure gauge should be set to coincide

with the indicating pointer.

6.3 Initial Lighting and Testing - All Systems

Refit the outer case, see diagram 4.1.

Identify the controls be reference to diagram 6.1.

Turn the control thermostat control knob “A” to “O” the Off

position, see diagram 6.1.

Diagram 5.2

WIRING DIAGRAM FOR CONTROL BOX.

SWITCHED

CONTROL

TIME SWITCH

PROGRAMMER

ETC.

(if fitted)

CIRCULATION

PUMP

240V~ 50Hz

PERMANENT

MAINS SUPPLY

FUSED AT 3A

L

N

L

N

BROWN

BLUE

GRN/YEL

GAS VALVE

BROWN

BROWN

RED

RED

PURPLE

BLUE

BROWN

BLUE

GRN/YELLOW

CHASSIS

EARTH

POST

3

7

6

8

9

Remove Red Link

between 9 and SL

when fitting a time

control etc.

(If link is not

removed the

circulation pump

will run constantly. )

7

8

9

7

8

9

N

L SL

N

L

SL

COMBINED THERMOSTAT AND

PUMP OVERRUN

5353

GRN/YELLOW

BROWN

BLUE

WHITE

F.B.S.D.

Remove the pressure test point screw “K” and fit a suitable

pressure gauge.

Turn the electrical supply on and check that the pump is

working.

Open all windows and put out any naked lights, pipes, cigarettes

and the like.

Turn on the main gas supply and purge in accordance with the

current issue of BS6891.

Turn the boiler gas service cock “J” to On.

Note. Make sure that the flue blockage safety device reset

button “M” is fully pushed in.

Push in control button “B”, keep pushed in and at the same time

operate the piezo button “C” until the pilot burner lights. After the

pilot burner lights keep the button “B” pushed in for about 15

seconds. If the pilot burner fails to light or stay alight a safety

device prevents immediate relighting. Do not attempt to relight

until the safety device has reset.

Note. Should the boiler fail to operate correctly refer to Fault

Finding Section.

Check the length of the pilot flame, it should envelop the

thermocouple tip as shown in diagram 7.7. The pilot rate can be

adjusted by turning screw “H”, having first removed the gas

valve cover by releasing the screws, see diagram 6.1.

Test pilot supply connections for soundness with a suitable leak

detection fluid.

6 Commissioning