3

221462C

Instructions for Use

General Notes and Information

Please read these instructions and follow them carefully for the

safe and economical use of your boiler.

Important Notice

This boiler is for use only on G20 gas.

The convection air openings on the boiler must NEVER be

obstructed.

The Gas Safety (Installation and Use)

Regulations

In your interests and that of gas safety it is the Law that ALL gas

appliances are installed by a competent person in accordance

with the current issue of the above regulations.

Maintenance

To ensure the continued efficient and safe operation of the boiler

it is recommended that it is checked and serviced at regular

intervals. The frequency of servicing will depend upon the particular

installation and usage, but in general once a year should be

enough.

To obtain service, please call your installer, or Heatcall (Glow-

worm’s own service organisation) using the telephone number

given on the controls tray.

If the appliance is installed in a rented property there is a duty of

care imposed on the owner of the property by the current issue of

the Gas Safety (Installation and Use) Regulations, Section 35.

It is the Law that servicing is carried out by a competent person.

Please be advised that the ‘Benchmark’ logbook should be

completed by the installation engineer on completion of

commissioning and servicing.

All CORGI Registered Installers carry a CORGI ID card, and have

a registration number. Both should be recorded in your boiler

Logbook. You can check your installer is CORGI registered by

calling CORGI direct on :- 01256 372300.

Gas Leak or Fault

If a gas leak or fault exists or is suspected the boiler must be turned

off also the electrical supply. Advice/help should be obtained from

your installation/servicing company or the local gas company.

Protection Against Freezing

If the boiler is to be out of use for any long period of time during

severe weather conditions we recommend that the whole of the

system, including the boiler be drained off to avoid the risk of

freezing up. If an immersion heater is fitted in the domestic hot

water cylinder make sure that it is switched off.

If you have a sealed water system you should contact your

installer/servicing company as a sealed water system should only

be drained, refilled and pressurised by a competent person.

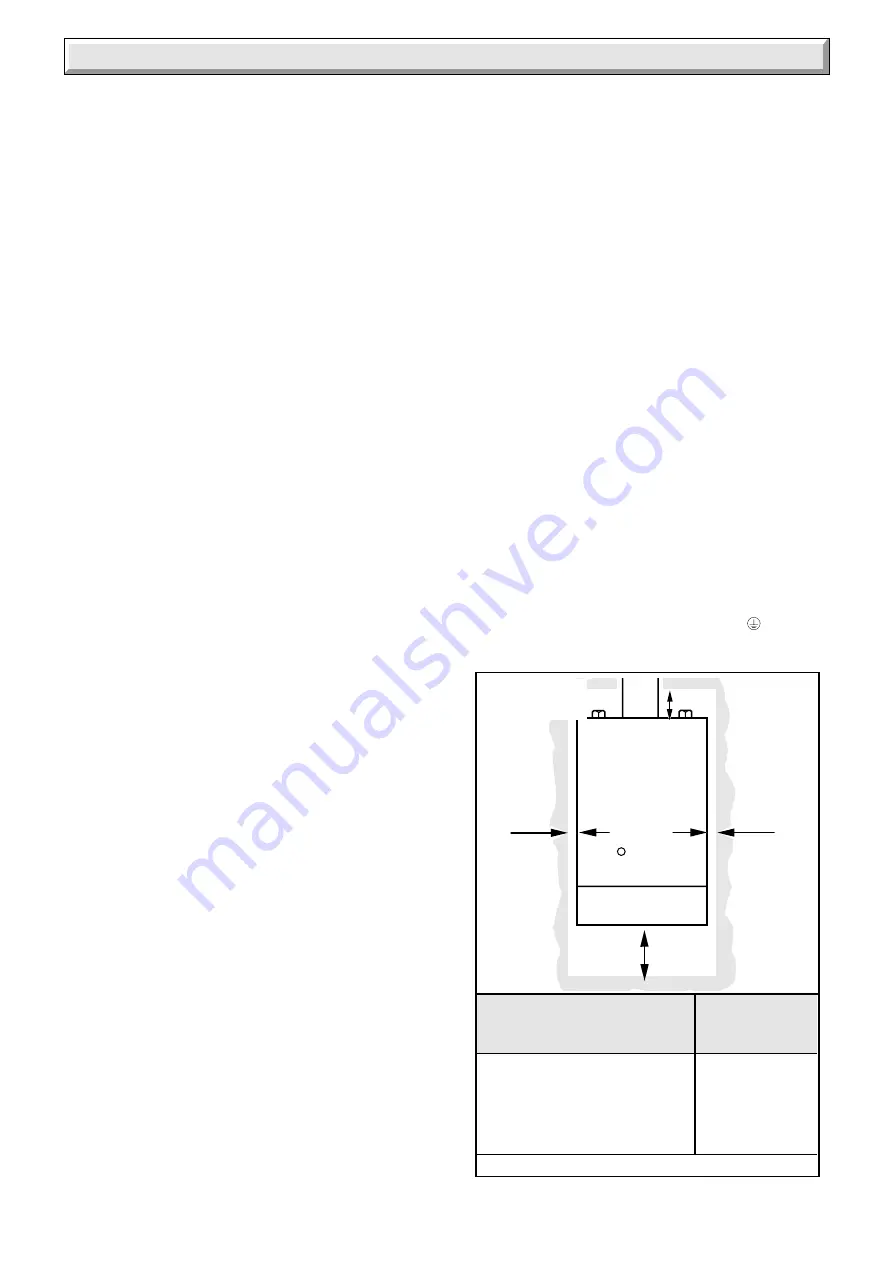

Boiler Clearance

The boiler must be positioned so that at least the minimum

operational and servicing clearances are provided, see diagram

1.

If fixtures are positioned close to the boiler they should be made

removable for access to pipework.

Enough space must be left in front of the boiler for servicing.

Boiler in a Compartment

If the boiler is fitted in a compartment or cupboard, purpose built

ventilation must be provided and kept clear.

Do not use the enclosed space for storage.

Boiler Identification

The type of boiler and its output can be checked against the

details inside the controls cover.

Overheat Cutoff Device

The boiler is fitted with a safety device to prevent damage

through overheating. Should the boiler go out together with the

pilot for no apparent reason, allow the system to cool down, then

relight the boiler.

Should the problem persist, turn the boiler off and consult your

installation/servicing company.

Electrical Supply

WARNING. The boiler must be earthed.

The boiler must only be connected to a 240V~50Hz supply,

protected by a 3A fuse, maximum.

All wiring must be in accordance with the current issue of

BS7671.

Heat resistant cable having a conductor size of 0.75mm

2

, (24/

0.20mm) to BS6500 Table 16 must be used.

The colours of three core flexible cable are, Brown - live, Blue -

neutral, Green and yellow - earth.

As the marking on your plug may not correspond with these

colours continue as follows:

The wire coloured brown must be connected to the terminal

marked “L” or “Red”.

The wire coloured blue must be connected to the terminal

marked “N” or “Black”.

The wire coloured green and yellow must be connected to the

terminal marked “E”, Green or the earth symbol

.

A L.H. and R.H. side of casing

25

B Top of casing

75

C Bottom of casing

150

D Front of boiler (from a

permanent surface

305

OPEN FLUE BOILERS

Minimum Clearances from

Walss, Ceiling, Floor, etc.

Diagram 1

MINIMUM

CLEARANCES

A

B

2390

A

C