26

221129A

1 1 C o m m i s s i o n i n g

The burner pressure is factory preset and no adjustment

should be required.

Check that all remote heating system controls, room

thermostats, integral clock and the like are switched on/

programmed and calling for heat.

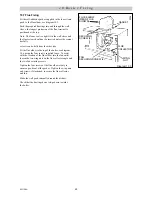

Set switch “C” to “On” as shown in diagram 11.1.

The pump will circulate water through the boiler and the

main burner will light.

Check that the burner pressure, with the heating system

cold to prevent any modulation of the gas pressure, is

/-0.2mbar (+/-0.08in wg) of 8.2mbar (3.4in wg),

SIT and 9mbar (3.4in wg), Honeywell, the central

heating pressure. If the burner pressure is incorrect, it

may be adjusted to the correct setting by turning the

central heating gas pressure adjuster (potentiometer),

using an insulated screwdriver, see diagram 11.6.

Turn the adjuster slowly, always making adjustment by

reducing below the required pressure then increasing up

to the required setting, (turn clockwise to increase).

Isolate the boiler from the electrical supply.

Remove the pressure gauge and tighten the test

point screw.

Note. It will be necessary when finally mounting the

clock to reposition the gas valve solenoid and

thermocouple lead.

Fit the cover and secure the control housing with the

screws previously removed.

Test for gas soundness around the burner pressure test

point with the main burner alight, using leak detection

fluid. Take care not to splash any of electrical

components.

SIT only - Refit the piezo bracket.

11.9 Temperature Settings

The domestic hot water outlet and central heating flow

temperatures are factory preset and sealed, therefore

cannot be adjusted.

The nominal temperature setting for the domestic hot

water outlet is 60

o

C (140

o

F) at a flow rate of

3.6Litre/min (0.8gall/min).

The nominal maximum flow temperature setting for

central heating is 82

o

C (180

o

F).

11.10 Heating System - Commissioning

Check that all remote controls and integral clock are

calling for heat.

Fully open all radiator valves, flow control valve “A”

and bypass valve “B”, see diagram 4.2.

Set the heating system in operation and balance

the radiators.

Adjust the control valve “A” to achieve the required

system differential temperature between the flow

and return.

Turn off all radiators, then adjust bypass valve “B” to

achieve the same temperature difference between the

boiler flow and return.

Refer to Section 4.6 and diagram 4.1/4.1A.

Allow the system to reach maximum temperature then

switch off, isolate the boiler from the electrical supply

and drain the system rapidly whilst still hot.

Fill and vent the system as described in Section 11.2

“Filling the Central Heating Circuit”. Add inhibitor, if

applicable, refer to Section 4.10 “Inhibitor”.

Lower the pressure to the initial cold fill design pressure,

using the external draining tap, close to the boiler, refer

to Section 4.11.

Lock or remove the handles from the spindles of flow

control valve “A” and bypass valve “B” to prevent

unauthorised adjustment.

The permanent mains electrical supply to the boiler must

not be switched off whilst the pilot flame is alight.