9

221129A

4 H e a t i n g S y s t e m

4.1 General Notes

The boiler is intended for use in a sealed system only.

4.2 Safety Valve

The safety valve is an integral part of the boiler.

It cannot be adjusted but has a manual test device.

4.3 Pressure Gauge

A pressure gauge is incorporated into the boiler to

indicate the system pressure.

The gauge has a cold fill set pointer.

4.4 Pump

The circulation pump is integral with the boiler.

The remaining circulating pressure head available from

the boiler is shown in diagram 4.1, Grundfos or diagram

4.1a, Glow-worm Wilo.

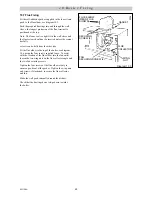

4.5 Expansion Vessel

The boiler has an integral expansion vessel with a

capacity of 8Litres, (1.76gall). If the system water

content exceeds the maximum quoted in Section 1, Data,

an additional vessel should be connected into the system

as close as possible to the central heating return

connection of the boiler, see diagram 4.2.

The pressure shall not be less that the static head at the

point of connection, that is, the height of the top point of

the system above the expansion vessel.

4.6 Flow Rate

A valve must be incorporated in the main flow or return

of the system, valve “A” shown in the flow diagram 4.2.

This valve must be lockable and positioned so that

inadvertent closure or unauthorised interference is not

possible. The design differential can be between 11

o

C

(20

o

F) and 17

o

C (30

o

F), dependent upon the system

resistance and the available pump head.

Grundfos Pump

The pump adjuster should normally be left at maximum

(3) but in some cases it is permissible to adjust the pump

to a lower setting (2), see diagram 4.1.

To use diagram 4.1 start with the required heating

system load.

In the example shown the maximum boiler output has

been chosen, 16.1kW (55,000Btu/h).

Draw a horizontal line from the required system

differential temperature axis to intersect the curve.

In the example 11

o

C (19.8

o

F) has been chosen,

shown - - - - -. At the point of intersection draw a

vertical line to cross the pump curve, from this point

draw a further horizontal line to determine the available

pump head. In the example 2.7m (9ft) is available. A

greater pump head can be achieved by choosing a higher

system differential temperature, up to a maximum of

4.6m (15ft) at a system differential of 17

o

C (30.6

o

F).

The system must be designed such that the available

pump head is not exceeded.

If the heating system load is less than 13.2kW

(45,000Btu/h) then it is permissible to adjust the pump

setting to (2), shown This results in an available

pump head of 2.1m (7ft). This is the maximum that can

be achieved with the pump at this setting.

Glow-worm Wilo Pump

The pump adjuster should normally be left at maximum

(2) but in some cases it is permissible to adjust to a lower

setting (1), see diagram 4.1a.

To use diagram 4.1a start with the required heating

system load.

In the example shown the maximum boiler output has

been chosen, 16.1kW (55,000Btu/h).

Draw a horizontal line from the required system

differential temperature axis to intersect the curve. In

the example 11

o

C (19.8

o

F) has been chosen,

shown . At the point of intersection draw a

vertical line to cross the pump curve. From this point

draw a further horizontal line to determine the available

pump head. In the example 2.7m (9ft) is available. A

greater pump head can be achieved by choosing a higher

system differential temperature, up to a maximum of

4.6m (15ft) at a system differential of 17

o

C (30.6

o

F).

The system must be designed such that the available

pump head is not exceeded.

If the heating system load is less than 13.2kW

(45,000Btu/h) then it is permissible to adjust the pump

setting to (1), shown This results in an available

pump head of 4.2m (13ft9in). This is the maximum than

can be achieved with the pump at this setting.