0020239562_04 EASICOM 3 Installation and maintenance instructions

21

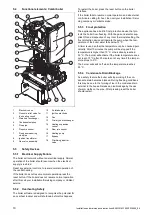

7.7

Connecting the drain cock

1

▶

Connect a hose to the drain cock

(1)

and guide the free

end of the hose to a suitable drainage point.

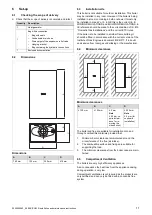

7.8

Flue installation

7.8.1

Installing and connecting the air/flue pipe

1.

You can find out which air/flue pipes may be used by

consulting the enclosed set-up instructions for the

air/flue system.

2.

Observe the information on positioning the air/flue ter-

minal.

Condition

: Installation in damp rooms

▶

You must connect the product to a room-sealed air/flue

system. The combustion air must not be taken from the

installation site.

3.

Install the air/flue pipe using the set-up instructions.

7.9

Electrical installation

Only qualified electricians may carry out the electrical install-

ation.

The product must be earthed.

Danger!

Risk of death from electric shock!

The power supply terminals L and N remain

live even if the product is switched off:

▶

Switch off the power supply.

▶

Secure the power supply against being

switched back on.

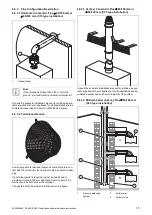

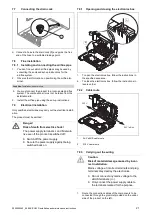

7.9.1

Opening and closing the electronics box

B

B

A

1.

To open the electronics box, follow the instructions in

the specified sequence.

2.

To close the electronics box, follow the instructions in

reverse order.

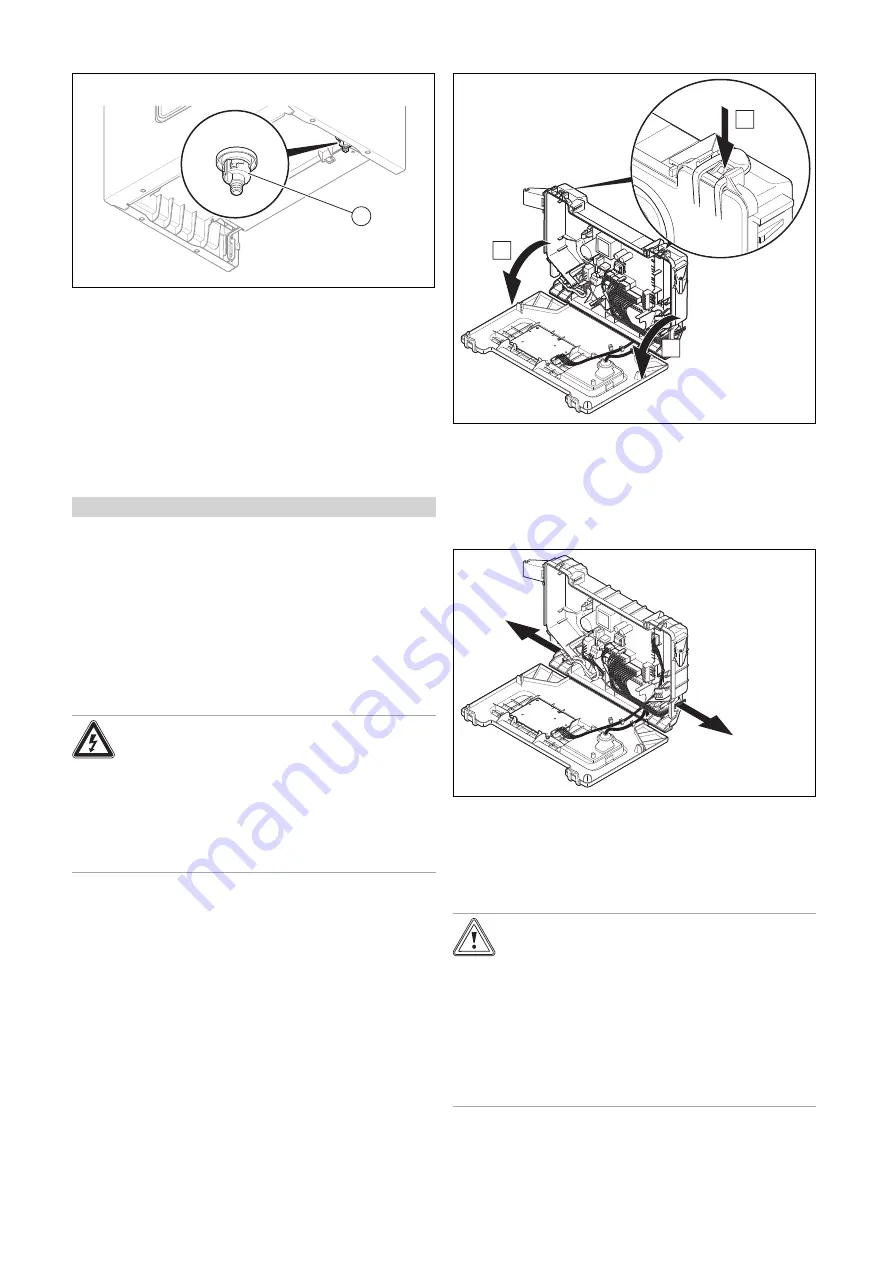

7.9.2

Cable route

230V

24V / eBus

1

24-V eBUS cable route

2

230 V cable route

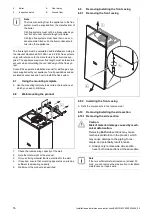

7.9.3

Carrying out the wiring

Caution.

Risk of material damage caused by incor-

rect installation.

Mains voltage at incorrect terminals and plug

terminals may destroy the electronics.

▶

Do not connect any mains voltage to the

eBUS terminals (+/-).

▶

Only connect the power supply cable to

the terminals marked for the purpose.

1.

Route the connection cables of the components to be

connected through the grommet provided on the under-

side of the product on the left.

Summary of Contents for EASICOM 3 24c

Page 1: ...en Installation and maintenance instructions EASICOM 3 24c 28c 0020239562_04 31 07 2020 ...

Page 54: ......

Page 55: ......