Start-up 6

0020201109_01 Energy Installation and maintenance instructions

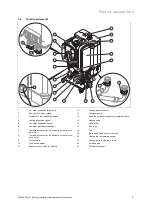

15

10mm

A

B

C

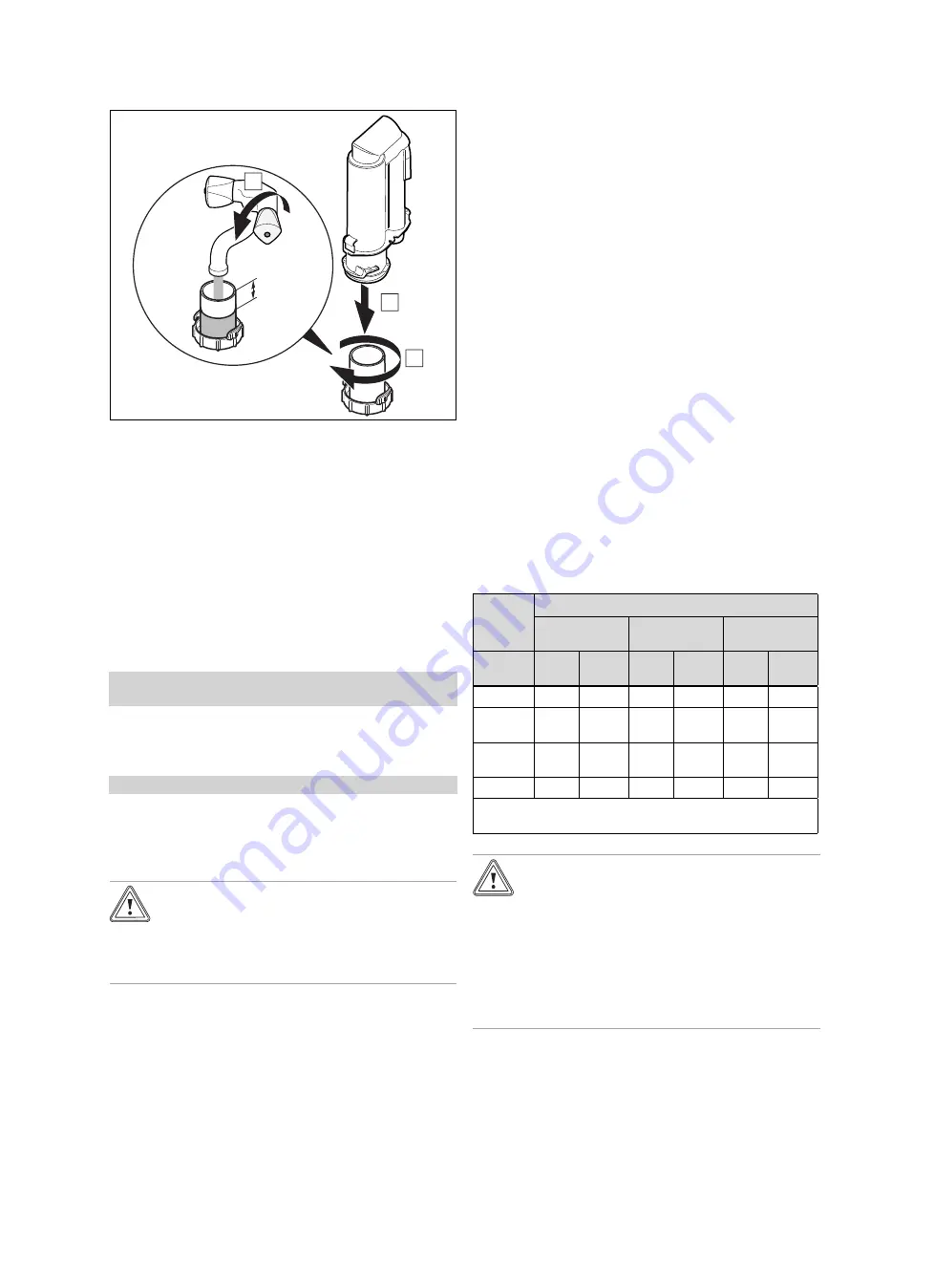

2.

Detach the siphon.

3.

Clean the lower section of the siphon with clean water.

4.

Fill the lower section of the siphon with water.

–

Distance between the edge of the condensate si-

phon and the water: 10 mm

5.

Screw in the siphon tightly.

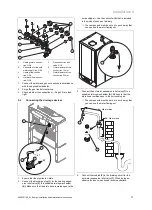

6.3

Checking the factory setting

The product's combustion has been factory tested and pre-

set for the type of gas indicated on the identification plate.

▶

Check the information about the type of gas indicated on

the identification plate and compare this with the type of

gas available at the installation location.

Conditions

: The product design

is not compatible

with the local gas

group

▶

Do not start up the product.

▶

Carry out a gas conversion in accordance with your sys-

tem .

Conditions

: The product design

is compatible

with the local gas group

▶

Proceed as described in the instructions below.

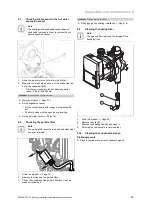

6.4

Checking and treating the heating

water/filling and supplementary water

Caution.

Risk of material damage due to poor-qual-

ity heating water

▶

Ensure that the heating water is of suffi-

cient quality.

▶

Before filling or topping up the system, check the quality

of the heating water.

Checking the quality of the heating water

▶

Remove a little water from the heating circuit.

▶

Check the appearance of the heating water.

▶

If you ascertain that it contains sedimentary materials,

you must desludge the system.

▶

Use a magnetic rod to check whether it contains mag-

netite (iron oxide).

▶

If you ascertain that it contains magnetite, clean the sys-

tem and apply suitable corrosion-protection measures, or

fit a magnet filter.

▶

Check the pH value of the removed water at 25 °C.

▶

If the value is below 8.2 or above 10.0, clean the system

and treat the heating water.

▶

Ensure that oxygen cannot get into the heating water.

(

→

Page 20)

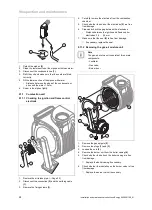

Checking the filling and supplementary water

▶

Before filling the system, measure the hardness of the

filling and supplementary water.

Treating the filling and supplementary water

▶

Observe all applicable national regulations and technical

standards when treating the filling and supplementary

water.

Provided the national regulations and technical standards

do not stipulate more stringent requirements, the following

applies:

You must treat the heating water in the following cases:

–

If the entire filling and supplementary water quantity dur-

ing the operating life of the system exceeds three times

the nominal volume of the heating installation, or

–

If the guideline values listed in the following table are not

met, or

–

If the pH value of the heating water is less than 8.2 or

more than 10.0.

Total

heating

output

Water hardness at specific system volume

1)

≤

20 l/kW

> 20 l/kW

≤

50 l/kW

> 50 l/kW

kW

ppm

CaCO

₃

mol/m

³

ppm

CaCO

₃

mol/m

³

ppm

CaCO

₃

mol/m

³

< 50

< 300

< 3

200

2

2

0.02

> 50

to

≤

200

200

2

150

1.5

2

0.02

> 200

to

≤

600

150

1.5

2

0.02

2

0.02

> 600

2

0.02

2

0.02

2

0.02

1) Nominal capacity in litres/heating output; in the case of multi-

boiler systems, the smallest single heating output is to be used.

Caution.

Risk of material damage if the heating

water is treated with unsuitable additives.

Unsuitable additives may cause changes in

the components, noises in heating mode and

possibly subsequent damage.

▶

Do not use any unsuitable frost and cor-

rosion protection agents, biocides or seal-

ants.

No incompatibility with our products has been detected to

date with proper use of the following additives.

▶

When using additives, follow the manufacturer's instruc-

tions without exception.

We accept no liability for the compatibility of any additive or

its effectiveness in the rest of the heating system.