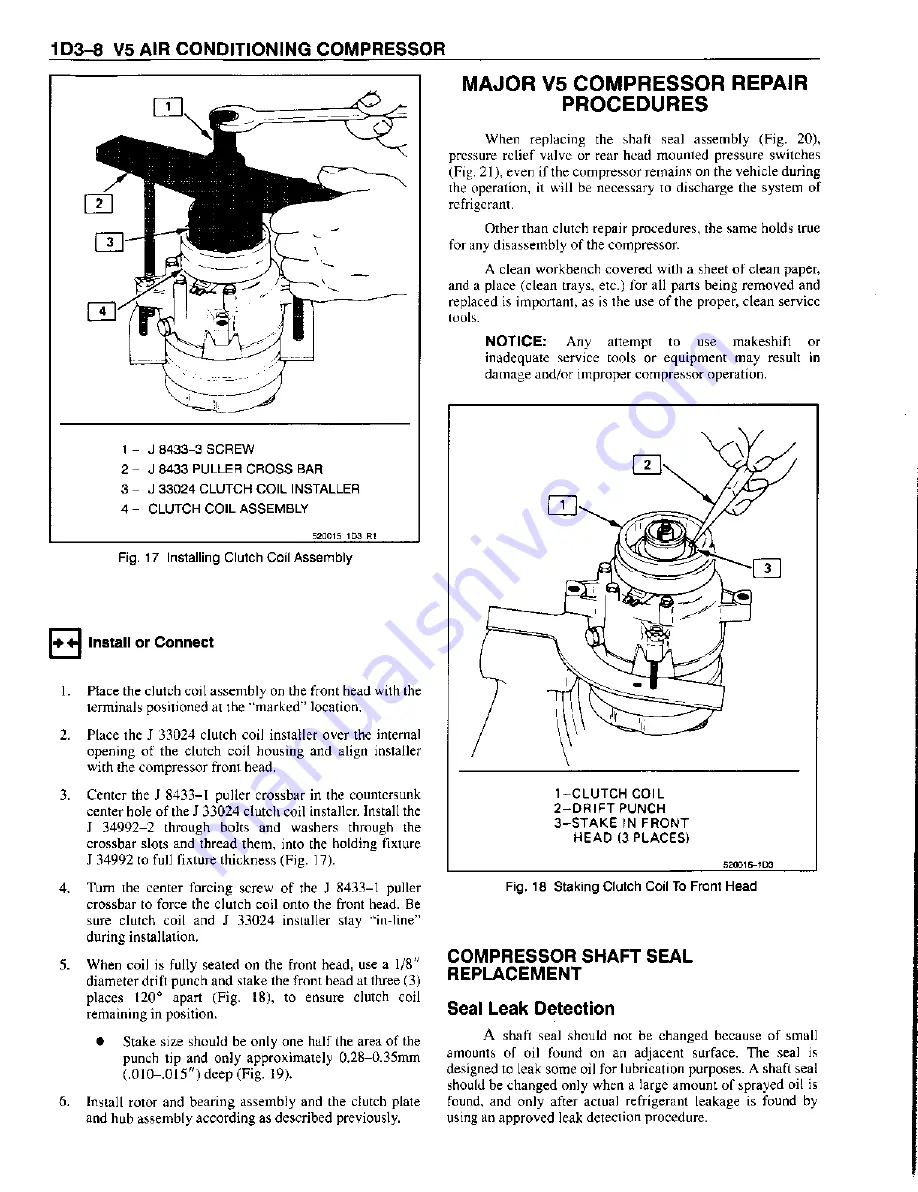

Fig. 17 Installing Clutch Coil Assembly

Install or Connect

1.

P lace the clutch coil assem bly on the front head with the

term inals positioned at the “m arked” location.

2.

P lace the J 33024 clutch coil installer over the internal

opening o f the clutch coil housing and align installer

w ith the com pressor front head.

3.

C enter the J 8433-1 puller crossbar in the countersunk

center hole o f the J 33024 clutch coil installer. Install the

J 3 4 9 9 2 -2 through bolts and w ashers through the

crossbar slots and thread them , into the holding fixture

J 34992 to full fixture thickness (Fig. 17).

4.

Turn the center forcing screw o f the J 8433-1 puller

crossbar to force the clutch coil onto the front head. Be

sure clutch coil and J 33024 installer stay “in-line”

during installation.

5.

W hen coil is fully seated on the front head, use a 1/8"

diam eter drift punch and stake the front head at three (3)

places 120° apart (Fig. 18), to ensure clutch coil

rem aining in position.

•

Stake size should be only one h alf the area o f the

punch tip and only approxim ately 0 .2 8 -0 .35mm

( .0 1 0 -.0 1 5 " ) deep (Fig. 19).

6.

Install rotor and bearing assem bly and the clutch plate

and hub assem bly according as described previously.

MAJOR V5 COMPRESSOR REPAIR

PROCEDURES

W hen replacing the shaft seal assem bly (Fig. 20),

pressure relief valve or rear head m ounted pressure sw itches

(Fig. 21), even if the com pressor rem ains on the vehicle during

the operation, it will be necessary to discharge the system o f

refrigerant.

O ther than clutch repair procedures, the sam e holds true

for any disassem bly o f the com pressor.

A clean w orkbench covered w ith a sheet o f clean paper,

and a place (clean trays, etc.) for all parts being rem oved and

replaced is im portant, as is the use o f the proper, clean service

tools.

NOTICE:

A ny

attem pt

to

use

m akeshift

or

inadequate service tools or equipm ent m ay result in

dam age and/or im proper com pressor operation.

1- C L U T C H C O IL

2 - D R I F T PUNCH

3 - S T A K E IN F R O N T

H E A D (3 PLACES)

____________________________________________________________ 520016-1D3_________

Fig. 18 Staking Clutch Coil To Front Head

COMPRESSOR SHAFT SEAL

REPLACEMENT

Seal Leak Detection

A shaft seal should not be changed because o f small

am ounts o f oil found on an adjacent surface. The seal is

designed to leak som e oil for lubrication purposes. A shaft seal

should be changed only w hen a large am ount o f sprayed oil is

found, and only after actual refrigerant leakage is found by

using an approved leak detection procedure.

1 - J 8433-3 SCREW

2 - J 8433 PULLER CROSS BAR

3 - J 33024 CLUTCH COIL INSTALLER

4 - CLUTCH COIL ASSEMBLY

__________________________________520015-1D3-R1

Summary of Contents for S Series 1994

Page 1: ......

Page 11: ...VIEW A p n n n j VIEW C F7554 Figure 10 Hydra Matic 4L60 E Transmission I D Location...

Page 24: ...NOTES...

Page 26: ......

Page 69: ...NOTES...

Page 71: ...3 2 STEERING...

Page 73: ......

Page 84: ......

Page 102: ...40...

Page 130: ...NOTES...

Page 146: ...NOTES...

Page 162: ...NOTES...

Page 166: ...Figure 5 Removing the Pinion Flange Figure 6 Pressing the Drive Pinion from the Cage...

Page 178: ...Figure 3 Spreading the Differential Case Figure 4 Removing the Differential...

Page 190: ...NOTES...

Page 202: ...NOTES...

Page 206: ...F5785...

Page 212: ...B Button Moved Out of Bearing Bore F5791...

Page 228: ...NOTES...

Page 232: ......

Page 234: ......

Page 236: ...Adjuster 63 Bolt 64 Lock Figure 10 Turning the Adjuster Plug K3 Models...

Page 237: ...Figure 13 Removing the Pinion Seal 39 Bearing Cup Figure 16 Removing the Inner Bearing Cap...

Page 261: ...F7475...

Page 267: ...B Button Moved Out of Bearing Bore F5791...

Page 294: ...NOTES...

Page 300: ...NOTES...

Page 318: ...NOTES...

Page 322: ...SR207LN2 EDS...

Page 324: ......

Page 326: ...OVERHEAD OILING AND RETURN MAIN OIL GALLERY N30005 6A2 J EDS...

Page 368: ...103 153 127 V1200...

Page 370: ......

Page 372: ......

Page 374: ...F9375 Figure 7 Engine Lubrication Diagram Engines Without Balance Shaft...

Page 376: ...Figure 9 Engine Lubrication Diagram Engines With Balance Shaft...

Page 399: ...V2974...

Page 410: ......

Page 412: ...195 196 201 174 252 163 165 164 244 3706r3924...

Page 452: ......

Page 454: ...163 164 V1202...

Page 456: ...20 21x 302 210 4 0 41 2 5 2 5 1 2 51 4 2 e3 54 3 9 252 252 S 255 255 25 6 256 209 V1196...

Page 458: ...100 1 8 4 185 183 177 v 75 201 3706r1204...

Page 460: ......

Page 510: ......

Page 512: ...V2131...

Page 514: ...110 106 106 103 90 93 89 88 87 86 v 7 7 7 7 j A _ 111 f t 2 a a s 53 49 L 47 46 3706r4751...

Page 516: ...259 260 150 237 S lM 180 167180 J 1 82 183 170 169 1 1 78 1 7 9 213212 2 0 7 205 r i 3706r4752...

Page 566: ...NOTES...

Page 574: ...NOTES...

Page 618: ...SPECIAL TOOLS...

Page 620: ...NOTES...

Page 672: ......

Page 682: ......

Page 686: ......

Page 694: ...RH0213 4L60 E...

Page 695: ...657 659 m i J 8092 H J 34196 4 3 34196 5 657 658 665 J 23907 J 7004 1 J 8092 RH0214 4L60 E...

Page 696: ...J 8092 J 34196 4 33 31 J 8092 RH0215 4L60 E...

Page 697: ...SPECIAL TOOLS...

Page 698: ...SPECIAL TOOLS...

Page 758: ...RH0194 4L80 E...

Page 764: ......

Page 770: ...SPECIAL TOOLS...

Page 771: ...SPECIAL TOOLS CONT...

Page 772: ......

Page 775: ......

Page 776: ......

Page 785: ......

Page 804: ...NOTES...

Page 806: ......

Page 808: ......

Page 822: ...3707r5079...

Page 840: ......

Page 848: ...NOTES...

Page 852: ......

Page 860: ...F5435...

Page 866: ......

Page 878: ...F9167...

Page 882: ...16 FrontOutputShaft 18 DrivtQNr 19 DrivenGm t 20 DriveChain 22 FrontOutputBearing V2836...

Page 890: ...F9168...

Page 908: ......

Page 919: ......