7

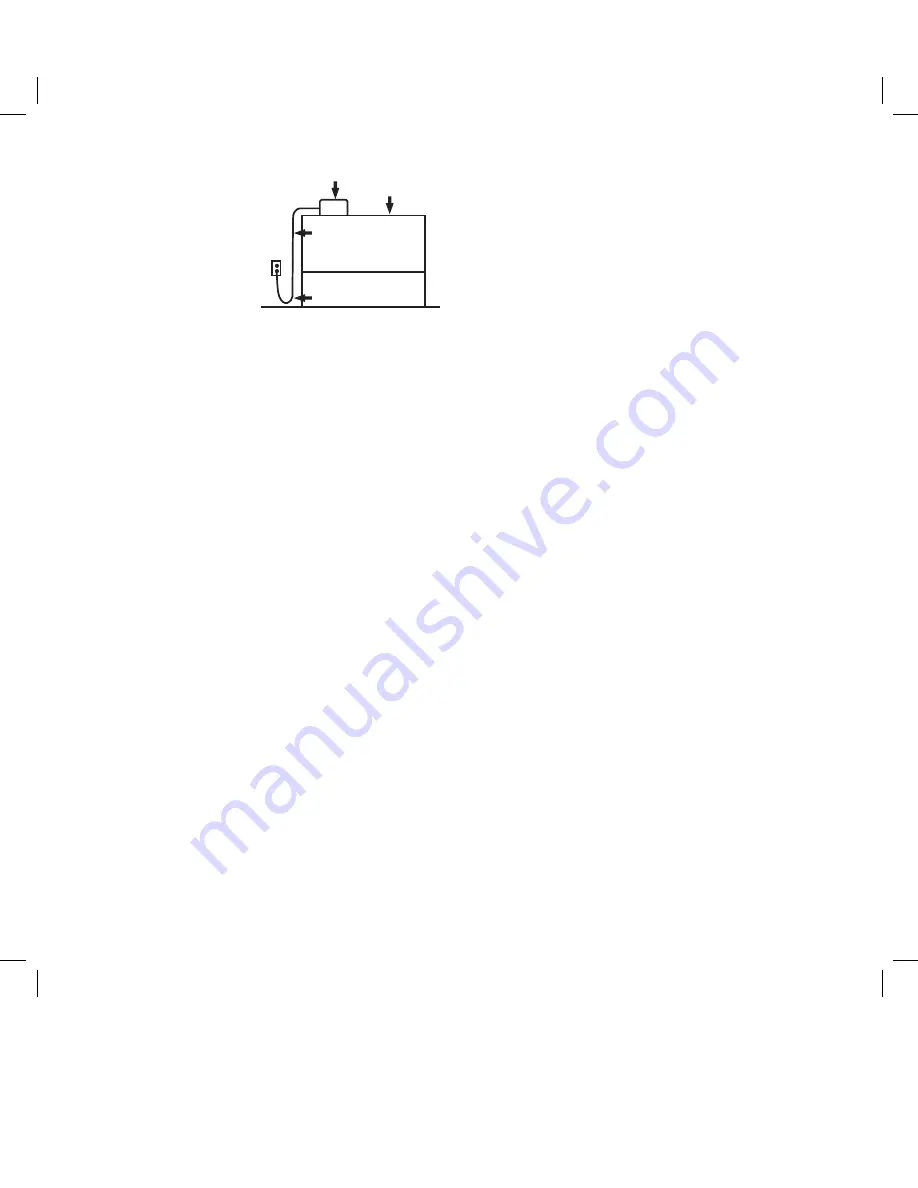

Position of tile saw

1. To avoid the possibility

of the appliance plug or

receptacle getting wet,

position tile saw to one

side of a wall mounted

receptacle to prevent

water from dripping onto

the receptacle or plug. The user should arrange a “drip

loop” in the cord connecting the saw to a receptacle.

The “drip loop” is that part of the cord below the level

of the receptacle, or the connector if an extension cord

is used, to prevent water travelling along the cord and

coming in contact with the receptacle.

2. If water is present have an electrician complete any

necessary work or repairs. DO NOT ATTEMPT ANY

REPAIRS YOURSELF.

Accessories

The GMC WTS550 tile cutting saw is supplied with the

following accessories as standard:

•

2 x Mitre blocks

•

Bevel plate

•

Socket spanner x1

•

Face spanner x1

•

200mm Diamond Blade (Fitted)

•

2 x Tile clamps

•

Support arms and fixing screws

•

Instruction manual

Required tools

A philips head screw driver is required to assemble the

support arms.

Unpacking

Due to modern mass production techniques, it is unlikely

that your GMC Power Tool is faulty or that a part is missing.

If you find anything wrong, do not operate the tool until the

parts have been replaced or the fault has been rectified.

Failure to do so could result in serious personal injury.

1. Remove all loose parts from the carton.

2. Remove the packing materials from around the saw.

3. Carefully lift the saw from the carton and place it on a

level work surface.

����

�����������������

������������������

���������