How to laminate

☞ Lamination

If the test lamination is acceptable, increase its speed for lamination.

Remarks : for the best embossing effect, we recommend 40㎛ Film for 150g papers

25㎛ Film for 200g papers.

※ This machine contains special speed and temperature control program to improve lamination quality.

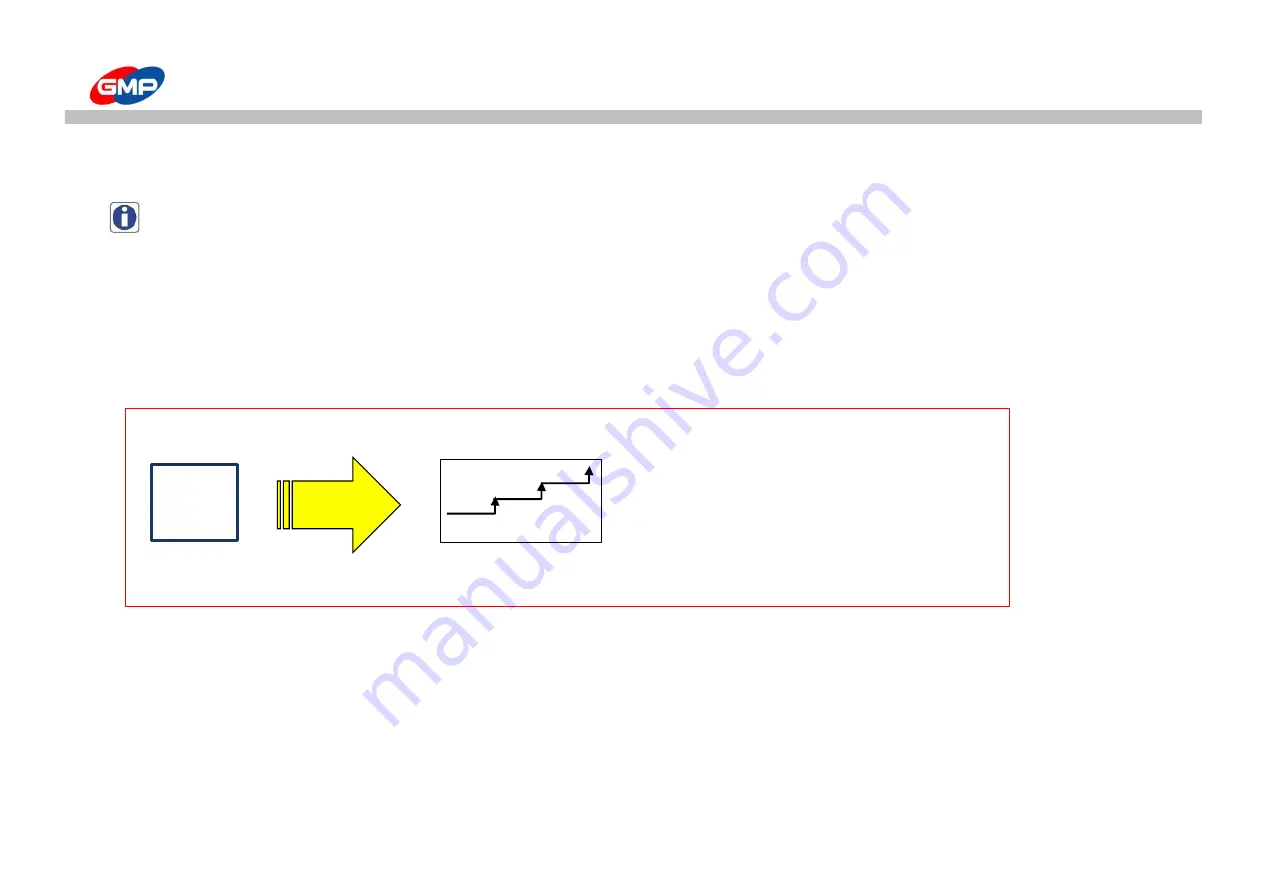

1. Soft Accelerate System

- This program is to apply the change of the job speed within 4secs if the job speed is rapidly increased.

This delays the temperature decrease caused by the high speed rotation to prevent the low temperature

that causes deterioration of laminating quality

2. Temperature control program

- the heater would be linked with speed to compensate the heat of the roller faster while the roller is on the job.

※ Notice for Lamination

1. Stop lamination could make a mark on a laminated results.

2. Basically, thicker substrates requires lower speed or higher temp.

3. Thinner substrates requires higher speed or lower temp.

4. For perfect lamination, similar materials lamination first and adjust the conditions for real lamination.

5. If substrate would not be fed properly, this could be a cause of wrinkle.

Start

(Speed 3)

KEY IN

(SPEED 13)

4sec 4sec 4sec

Example)

Starting job with a speed of 3 and increase the speed to 13

① The speed message will blink while changing

the speed

② The message will no longer blink when the

speed readches the set speed.

Remarks :

if the temperature of the roller is certain degrees lower than the set temperature while increasing the

speed, the speed will not increase from that point and "L-TEMP" message will appear on the display. this "L-TEMP"

message will be disappeared when the compensation of the temperature is made. Please increase the speed again after

32/51