SLEEKING(HOLOGRAM FINISH)

② Spot Hologram Sleeking

Temp. / Speed Setting

PRINTER

Refer to the Table 2.1

HP INDIGO 3500

XEROX 5252

POD Prints

(DIGITAL PRINT)

POD Prints

SLEEKING

FINISH

OFFSET 인쇄물

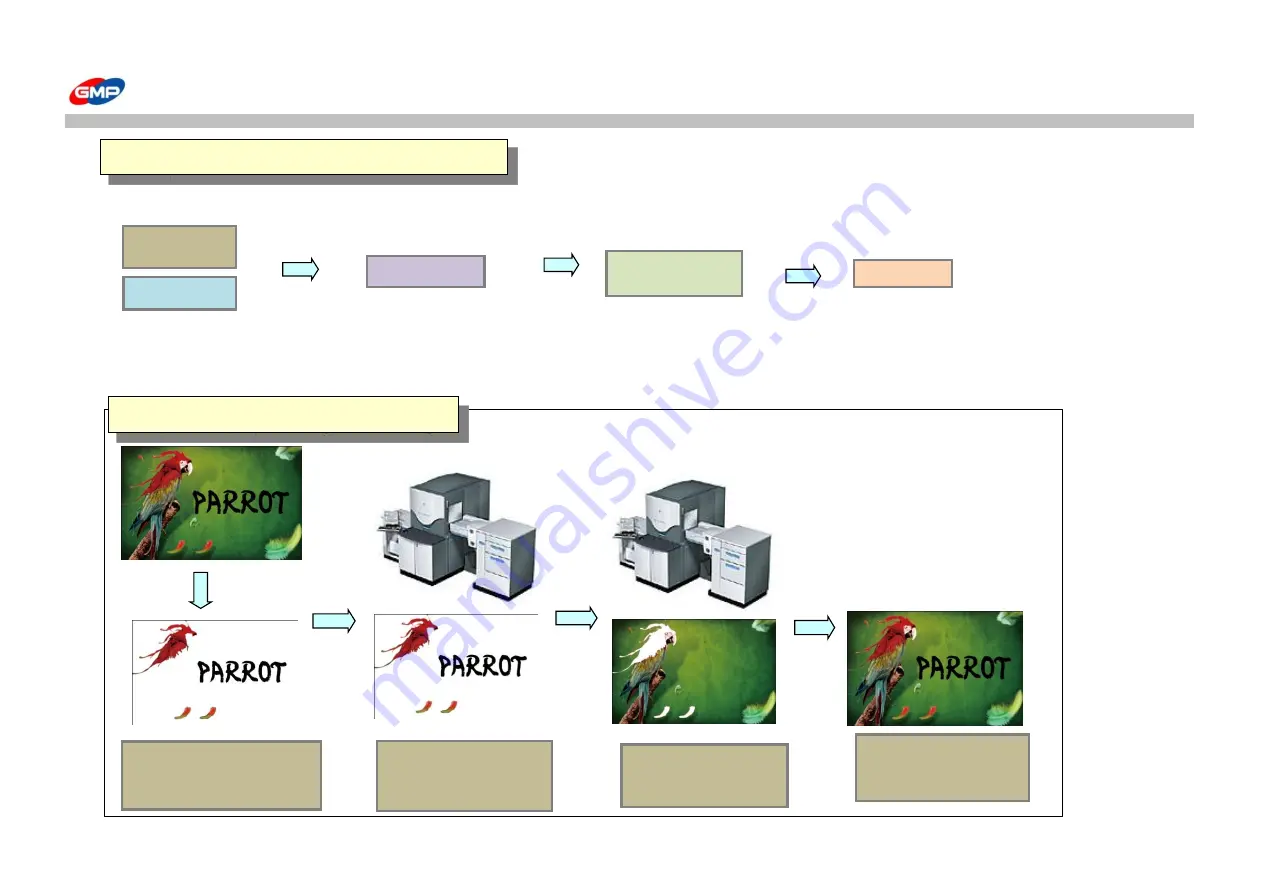

(Table.2.3) Spot Hologram Sleeking

2. Spot HOLOGRAM SLEEKING SOLUTION

1.Cut the Carrot

Image(Picture 2.1) with

Image Editing Program

3. Print the

Background Image.

6. Only the Spot

Image has Hologram

Sleeking Effect.

2. Print the Spot Image

only and Sleeking

47/51