How to laminate

1. How to load film

☞ Composition of Film installing devices

① Film Shaft : The film shaft is used to load a laminating roll films.

② Film Shaft Holder Fixing Pin. : Film Shaft Holder Fixing Pin is used to fix the Film shaft Holder.

③ Film Shaft Holder : The Film Shaft Holder is used to prevent the Film Shaft from moving

④ Film Core : Film Core is used to fix the laminating roll films.

※ How to install film

① Remove the Film Shaft Holder Fixing Pin and pull the Film Shaft Holder

② remove any side of Film Core by using the Film Shaft Holder Fixing Pin

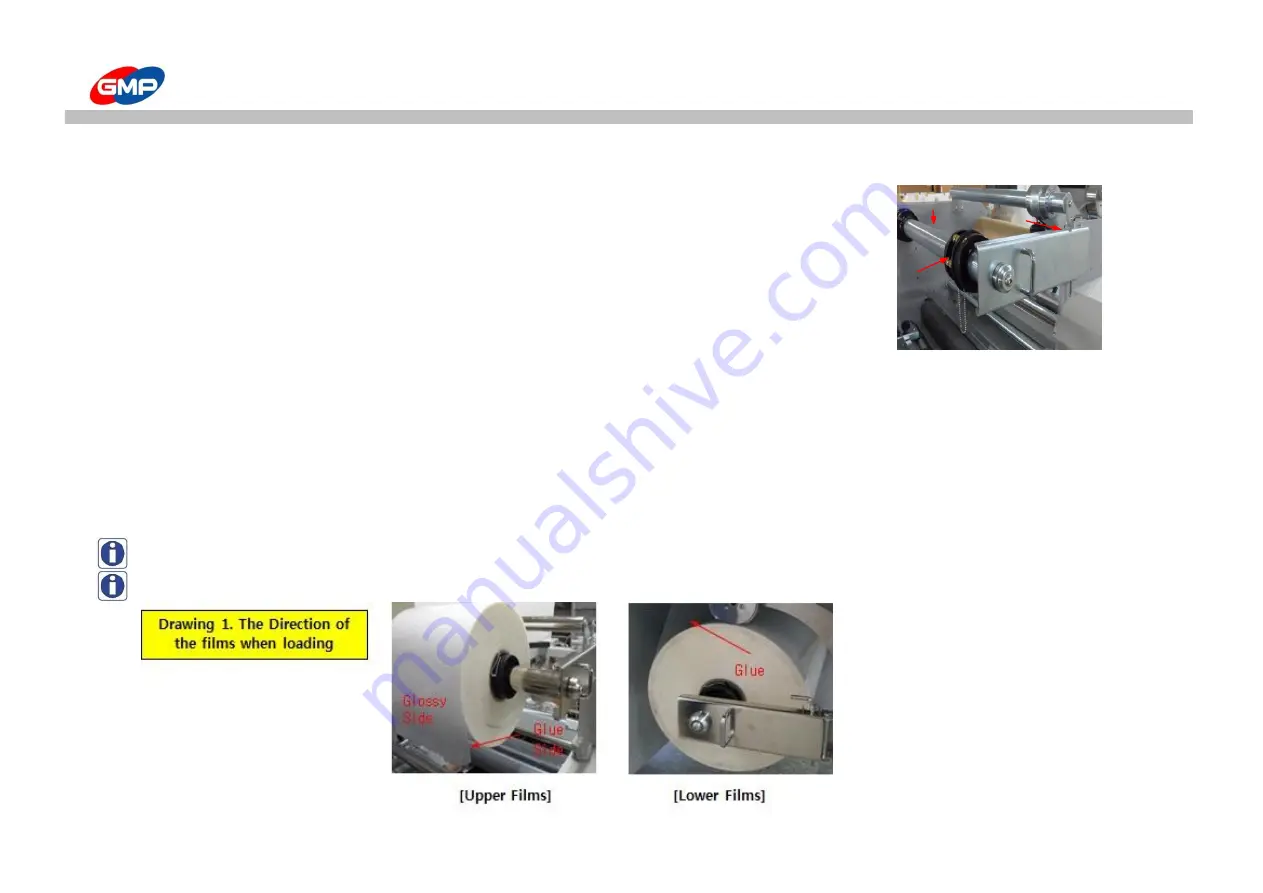

③ Insert or Remove film roll into or from Film Shaft. (Please refer to the Drawing 1)

④ Insert a film roll into the film shaft after the holder fixing pin is removed.

⑤ Tighten the Film core fixing bolt after film is loaded.

Remarks

: When doing

"Single side lamination"

please use 5~10mm narrower width films than substrate to prevent the contamination of cutting error

Remarks

: When doing

"Double side lamination"

Please use the same width for the upper and lower films to to prevent the contamination on roller.

②

①

③

④

37/60