1 0991 483

EN

-

21.12.2011

NGV A3

VALVE

M

ANUAL

I

NSTALLATION

, U

SE AND

M

AINTENANCE

43 / 46

1.05

ENG

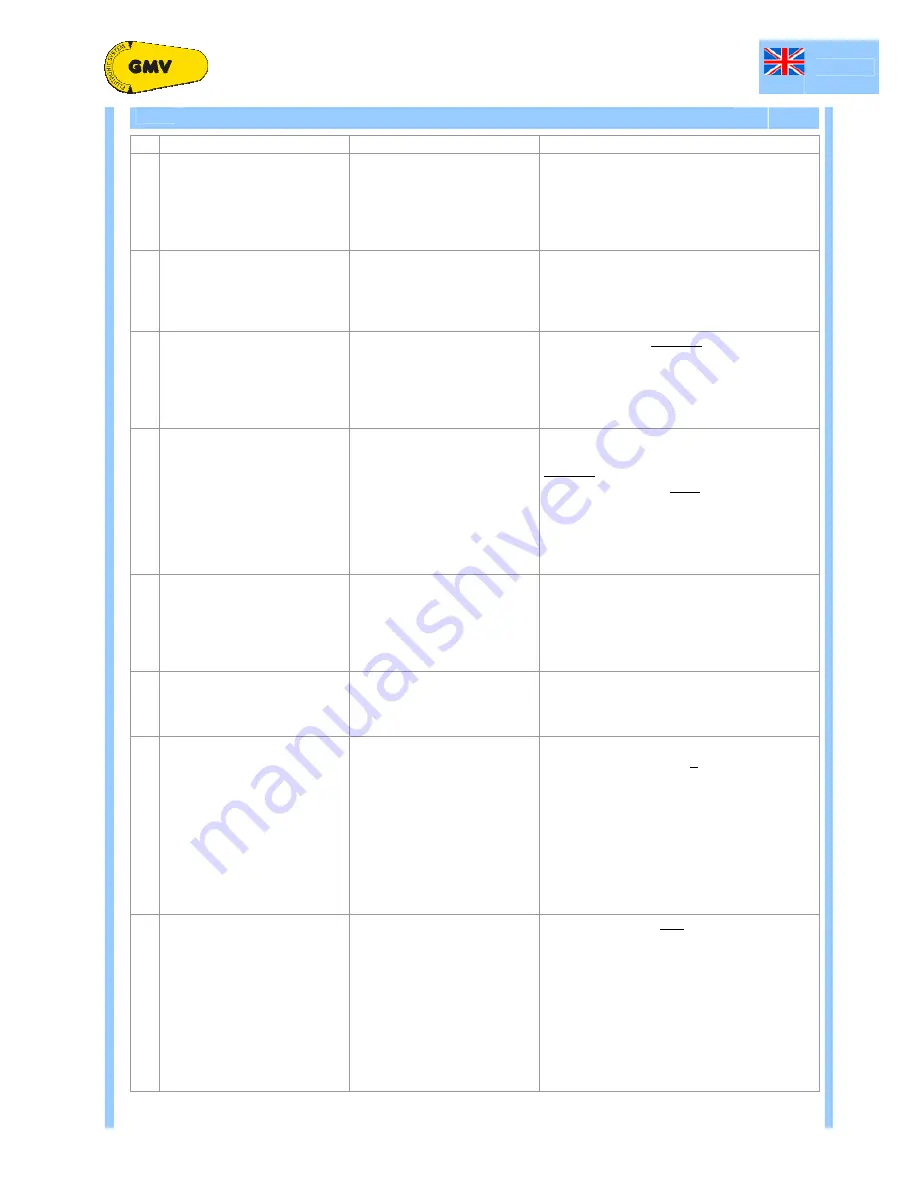

6.4.1 TROUBLESHOOTING

Fault

Possible cause

Possible solution

1 The system

- do not start but the pump

works

The card do not receive the

signal VS from the control

panel.

The control panel do not

receive/recognize the RUN

signal from the card.

Verify in the Menu 1.4 if the card receive

the signal VS from control panel. Verfy that

signals RDY and RUN are according to the

schema 2.3.3

2 The system

- run slowly in up and down

direction

- stops immediately without

deceleration

The Menu 5.12 is set on

“Install” and the system run

only in inspection speed.

The default parameter is “Install”. At the

end of the installation you must set the

parameter 5.12 = “Normal”

3 The system

- run only with low speed

The card

- do not receive the speed

signal (V0, V1, V2)

- receive the speed signal

after the direction signal (VS,

D)

Verify (menu 1.4 S0123DICA) that the card

receives the speed and the direction

signals.

If the card do not receives any signal check

the signal flow from the control panel and

repair the error.

4 The system

- has an abrupt departure in

up direction (run fast for

piece of the travel, slows,

and return to the correct

speed.

The motor starts before of

the RUN signal

Verify that the signals RUN and RDY are in

compliance with § 2.3.3. Verify (menù 1.4

S0123DICA) that all signals are received

and (menù 1.5 1234YND) send correctly

to/from the card.

The motor do not must start before:

- VS, up command

- RUN

- Out 4=UP if used

5 The system

- starts in up direction with

an not regular acceleration

(it starts with a little burst

and immediately return to

the correct acceleration)

The starting time is not

correct, the oil output line

was open in advance and

the oil reach the piston until

the motor is at full.

Increase the value of the menu point 6.8 to

delay the oil output line opening.

6 The system

- run irregularly and

inaccurate

The basic parameters are

not corrects

Verify (menu 5) that the values set are in

compliance with the effective system data.

Particularly, verify values 5.5 Pstat MIN e

5.6 Pstat MAX

7 The system

- stops over/under the

landing level when the

system has a reduced floor

distance (< 1,8m)

The system arrive at landing

in nominal speed (Vo)

instead of intermediate

speed V1.

The intermediate speed set

is too high

Verify that the card receives the speed

signal V1 (menu 1.4 S0123DICA). If the

card do not receive the signal check the

signal flow from the control panel and

repair the error.

If the card receive the signal you must

decrease the intermediate speed V1

parameter (in up direction menu 6.2, in

down direction menu 7.2 recommended

value 0,3 m/s) and/or increase the

deceleration distance.

8 The system

- do not decelerate correctly

The speed signals (V0, V1 o

V2) are not according with §

3.5 or the magnet position is

not correct

Verify (menù 1.4 S0123DICA) that the

status of the speed signal V0 changes from

1 to 0 when the car comes in the

deceleration zone.

Verify that the parameters 4.9, 4.10, 4.11 e

4.12 are correctly set (default = 0) and

otherwise, set the correct value.

Verify that the magnets are at the correct

distance from the floor

If the problem persist, please, contact the

technical support.

Summary of Contents for NGV A3

Page 47: ... ...