13

OPERATION OF EQUIPMENT

Drainage

Drainage of the air tank should be performed to eliminate the condensed water

accumulation inside the tank. The drainage frequency depends on environmental conditions

and operating time, on average the drainage is recommended to be done on a daily basis.

To perform the drainage, insert the hose which is connected to the register (12) located

underneath the tank inside a container for water disposal. Open the register slowly until all

the accumulated water is drained and air starts to flow again. Close the register firmly so

that no leakage can occur.

BioQualyAir 65L

BioQualyAir 40L

Compressed air outlet

The air pressure on the outlet can be adjusted through

the register (11), check the setting on the pressure gauge

(09). The air outflow rate can also be adjusted in the

register (10).

In tandem with the pressure and flow rate registers,

there is a filter that removes moisture and impurities

remaining in the air, the moisture that is removed from

the outlet will get stored in the reservoir (A), to empty it

press the pin underneath the reservoir.

11

09

A

10

12

12

PRECAUTIONS, RESTRICTIONS AND WARNINGS

This equipment must be transported and stored observing the following directions:

- Avoid falls and impacts;

- Keep it dry, do not expose it to rain, water drops or wet floor;

- Keep it away from water and direct sunlight, and in it original wrapping;

- Don’t move it over irregular surfaces, protect it from rain and observe the maximum

stack quantity specified in the packaging;

- Transportation and storage temperature range: -12°C to 50°C.

- Ambient temperature range recommended by 10 ° C to +35 ° C.

Transportation, storage and operation

Summary of Contents for BioQualyAir 40L

Page 1: ......

Page 9: ...9 TECHNICAL SPECIFICATIONS Dimensions mm BioQualyAir 65L BioQualyAir 40L ...

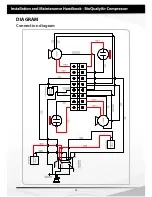

Page 24: ...24 DIAGRAM Connection diagram ...

Page 28: ......