5

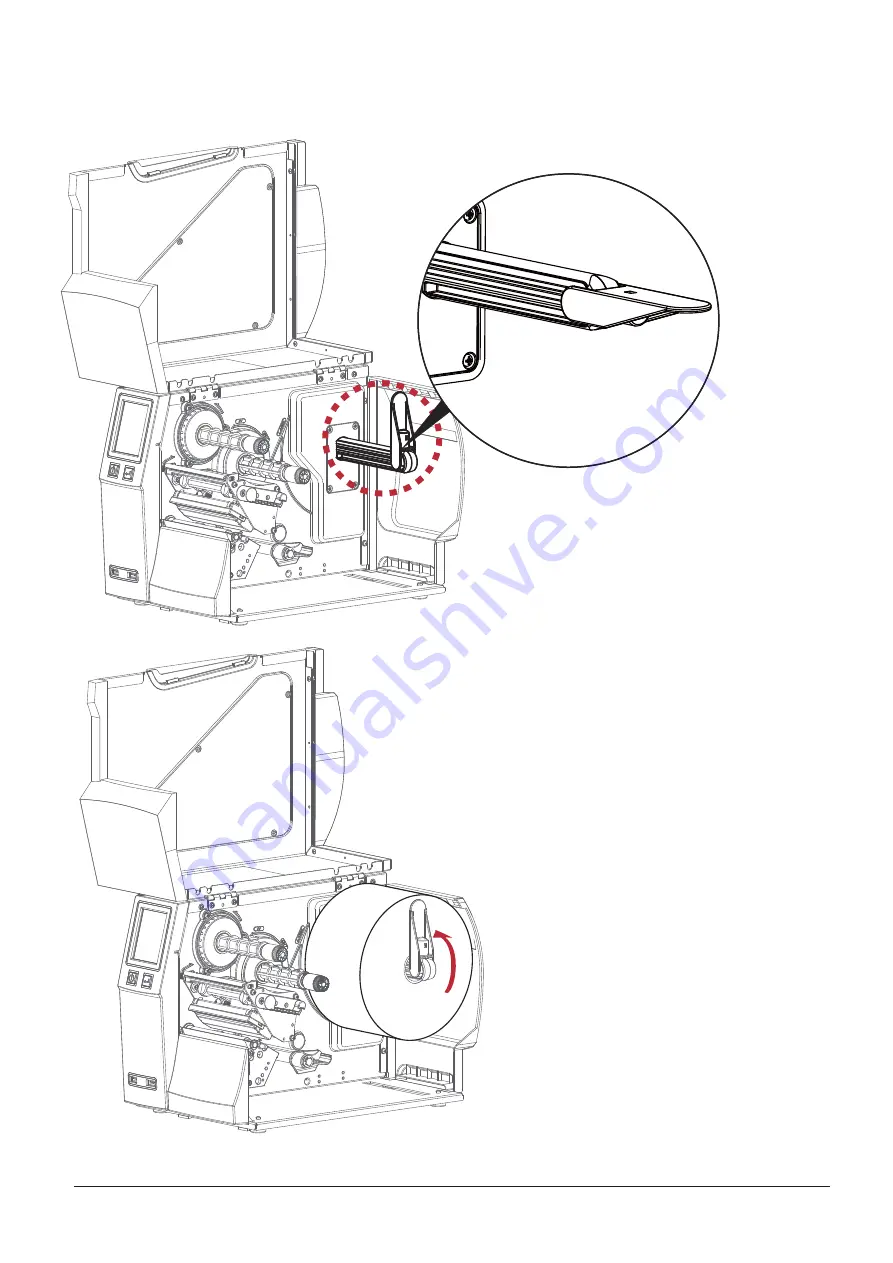

Now slide the label roll guide forward and fold it down

Place the label roll on the label supply hub

, pushing it right up to the printer housing.

(Do not apply too much pressure to avoid

damaging the label stock.)

*

:KHQPRYLQJWKHODEHOUROOJXLGHKROGLWRQO\E\WKHHQGWKDWLVDWWDFKHGWRWKHEUDFNHWQRWE\LWVWRS

1RWH

2

Printer Setup