Appendix

Appendix

INTERFACE

RT700i SERIES USER MANUAL

APPENDIX

Pinout Description

Connector Type : Type B

Serial Port

Default settings

:

Baud rate 9600, no parity, 8 data bits, 1 stop bit, XON/XOFF

protocol and RTS/CTS

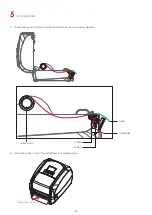

RS232 Housing(9-pin to 9-pin)

DB9 Socket

DB9 Plug

-

RXD

TXD

DTR

GND

DSR

RTS

CTS

RI

Computer

1 1

2 2

3 3

4 4

5 5

6 6

7 7

8 8

9 9

+5V, max 500mA

TXD

RXD

N/C

GND

RTS

CTS

RTS

N/C

Printer

*

***

The total current to the serial port may not exceed 500mA.

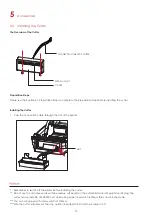

USB

Pin NO.

1

2

3

4

Function

VBUS

D-

D+

GND