Leak detector type LAG 2000 A

16 / 28

part no. 15 071 53 e

Installation dimension

a

for the LDL tank within the scope of replacing leak detectors

•

The minimum installation dimension amin for replacing leak detectors within the scope of

TRbF 501 is to be determined according to calculation equations [5] and [6] and be

complied with. The installation dimension

a

max

may not be exceeded and must be

determined according to calculation equation [4].

•

The following applies:

a

min

≤ a ≤

a

max

[1]

•

Distance between the check valve and the bottom of the LDL tank: ≥ 10cm

The arrangement of the LDL tank for above-ground and underground tanks is shown

schematically in

Figure 4

.

Calculation equations for installation dimension

a

(scope a TRbF)

a

min

=

D

x (

ρ

- 1) +

p

o,1

+ 30

[5]

Calculation equation [5] applies only with [6]

a

≥ w + 30

[6]

Tabelle 7:

The following changes compared to Table 6 (scope TRbF):

Symbol

Unit

Explanation

Comment

30

cm

Safety allowance

only for underground tanks

According to VdTÜV fact sheet 904

•

For underground tanks

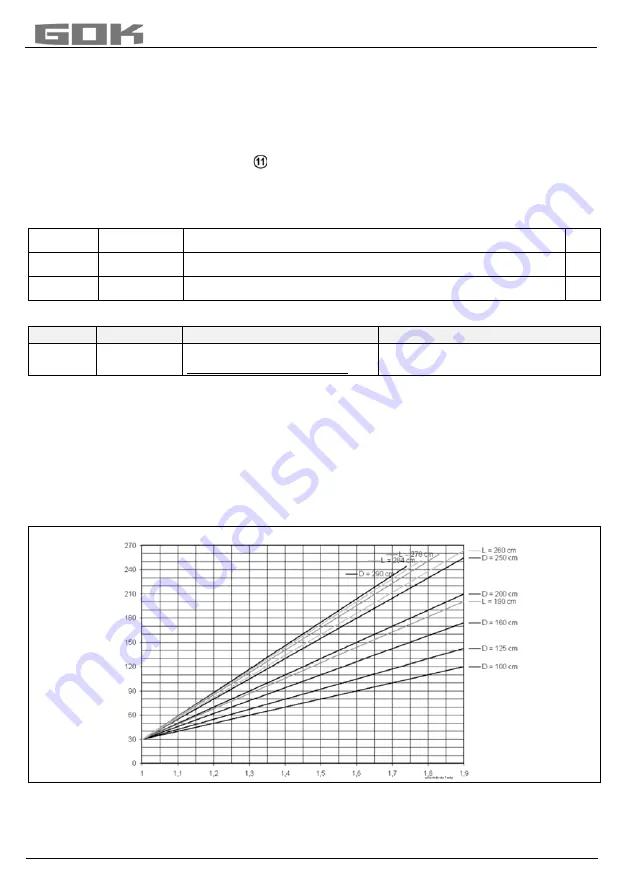

diagram 3

can be used to determine the minimum installation

dimension

a

min

in relation to the density of the storage medium with the parameter tank

diameter D or tank height

L

.

Assumed as:

p

s,2

= 550mbar,

w

= 0,

p

o,1

= 0

•

As opposed to calculating the installation dimension a according to EN 13160-3, when the

installation dimension a is calculated according to TRbF 501 and VdTÜV

fact sheet 904, the bottom of the LDL tank is used as the reference line.

Min. installation dimension

a

min

for underground tanks acc. to DIN 6608-2, DIN 6619-2

Diagramm 3:

Density of the storage medium in [kg/l]

M

ini

m

um

ins

ta

lla

tion di

m

ens

ion

a

m

in

[c

m]